En este artículo, exploraremos las causas comunes de sobrecarga en las punzonadoras, cómo detectarlas y solucionarlas, y las mejores soluciones para prevenirlas en el futuro. Ya sea operador, técnico de mantenimiento o gerente de fábrica, comprender cómo resolver y prevenir problemas de sobrecarga es crucial para mantener el rendimiento óptimo de su equipo de punzonado.

1. Comprensión de la sobrecarga de la máquina punzonadora

Antes de analizar las soluciones, es importante comprender qué significa la sobrecarga de la punzadora. La sobrecarga se produce cuando la punzadora se somete a una fuerza o tensión excesiva que supera su capacidad de diseño. Esto puede deberse a un exceso de trabajo, ajustes incorrectos o incluso al uso de un grosor de material inadecuado.

La condición de sobrecarga puede forzar los sistemas mecánicos, eléctricos e hidráulicos de la punzonadora, causando problemas como:

- Precisión de perforación reducida

- Desgaste excesivo de los componentes

- Aumento del tiempo de inactividad debido a reparaciones

- Posibles riesgos de seguridad para los operadores

La sobrecarga no solo tiene que ver con el estrés mecánico del equipo; también puede afectar la eficiencia general de la producción y resultar en reparaciones más costosas si no se aborda rápidamente.

2. Causas comunes de sobrecarga de la máquina punzonadora

Hay varias razones por las que una perforadora Puede experimentar sobrecarga. A continuación, destacamos las causas más comunes y cómo reconocerlas:

a. Espesor incorrecto del material

El uso de materiales demasiado gruesos para la punzonadora puede causar una tensión excesiva en los componentes de la máquina. Cada perforadora Tiene una capacidad nominal, y excederla puede provocar una sobrecarga. Por ejemplo, perforar láminas gruesas de acero inoxidable en una máquina diseñada para materiales más delgados puede provocar una sobrecarga.

b. Alta velocidad y velocidad de avance

Punzonar a velocidades y velocidades de avance superiores a las recomendadas puede aumentar la tensión en la máquina. Si se fuerza a la máquina a punzonar demasiado rápido, podría no ser capaz de soportar la tensión, lo que provocaría una sobrecarga. Los operadores deben comprender los parámetros de velocidad y avance especificados por el fabricante de la máquina.

c. Mantenimiento deficiente

La falta de mantenimiento rutinario puede causar fricción y otros problemas mecánicos que provocan sobrecarga. Componentes como la matriz de punzonado, el sistema hidráulico y el motor deben revisarse periódicamente para garantizar su correcto funcionamiento. Los filtros obstruidos, las piezas desgastadas y la falta de lubricación pueden hacer que el sistema trabaje más de lo necesario.

d. Configuración incorrecta de la máquina

Los ajustes incorrectos, como la configuración incorrecta de la carrera, pueden sobrecargar la máquina. Configurar la punzonadora para un punzonado más profundo o complejo sin tener en cuenta la resistencia del material puede sobrecargar el sistema.

e. Problemas del sistema hidráulico

El sistema hidráulico desempeña un papel crucial en el funcionamiento de las punzonadoras. Si la presión hidráulica no está correctamente calibrada o si los niveles de fluido hidráulico son bajos, la máquina puede sobrecargarse. Las fallas del sistema hidráulico también pueden provocar que la máquina ejerza demasiada fuerza, lo que provoca una sobrecarga.

3. Detección de sobrecarga en máquinas punzonadoras

Es importante detectar problemas de sobrecarga a tiempo para evitar mayores daños a la punzonadora. A continuación, se presentan algunas señales comunes de sobrecarga:

a. Sonidos inusuales

Escuchar ruidos fuertes o inusuales, como chirridos, chirridos o traqueteos, puede indicar que la máquina está bajo tensión y tiene dificultades para funcionar correctamente. Estos ruidos pueden indicar fricción entre piezas móviles u otros problemas mecánicos.

b. Resultados de perforación inconsistentes

Si observa que los punzones no son siempre limpios ni precisos, podría ser señal de que la máquina está sobrecargada. La fuerza de punzonado podría no ser uniforme, lo que provoca cortes irregulares.

c. Disminución de la velocidad de la máquina

Cuando una punzonadora se sobrecarga, puede empezar a disminuir su velocidad. Si nota una disminución en la velocidad de punzonado, podría deberse a que el sistema tiene dificultades para mantener los parámetros establecidos.

d. Sobrecalentamiento

El calor excesivo generado durante el funcionamiento puede ser un indicador de sobrecarga. Si la máquina se calienta demasiado, podría deberse a una fricción excesiva, una lubricación deficiente o un sistema hidráulico sobrecargado.

e. Daños visuales

Señales físicas como matrices de punzón agrietadas, herramientas dobladas o bastidores de máquinas deformados pueden ser evidentes en máquinas sometidas a sobrecarga. Estos problemas deben abordarse de inmediato para evitar daños mayores.

4. Cómo solucionar la sobrecarga de la punzonadora

Una vez identificada una situación de sobrecarga, es importante resolverla de inmediato para evitar daños y garantizar un funcionamiento continuo y sin problemas. Estos son los pasos clave para solucionar la sobrecarga de una punzonadora:

a. Ajustar la configuración de la máquina

Asegúrese de que todos los ajustes de la máquina, incluyendo la longitud de carrera, la velocidad de avance y la velocidad, estén configurados según los parámetros recomendados. Consulte el manual del fabricante para conocer los ajustes óptimos para el material y el espesor con el que trabaja. Ajustar los ajustes puede reducir la carga de la máquina y evitar la sobrecarga.

b. Inspeccionar y reemplazar componentes desgastados

La sobrecarga puede acelerar el desgaste de componentes críticos, como matrices de punzonado, válvulas hidráulicas y rodamientos. Las inspecciones periódicas permiten identificar piezas desgastadas que deben reemplazarse. Asegúrese de que todos los componentes mecánicos estén correctamente lubricados y limpios para evitar la fricción y la tensión.

c. Reducir el espesor del material

Si el material utilizado es demasiado grueso para la punzonadora, considere cambiar a un material más delgado que se ajuste a la capacidad nominal de la máquina. Como alternativa, ajuste la velocidad de punzonado y la velocidad de avance para adaptar el material más grueso o utilice una punzonadora con mayor capacidad de tonelaje.

d. Calibrar el sistema hidráulico

Asegúrese de que la presión hidráulica esté dentro de los límites recomendados. Si el sistema hidráulico presenta fallas, revise si hay fugas, niveles bajos de líquido u otros problemas. Asegúrese de cambiar el líquido hidráulico regularmente para garantizar un funcionamiento fluido.

e. Implementar el mantenimiento rutinario

Establezca un programa de mantenimiento regular para garantizar la inspección, limpieza y lubricación de todas las piezas. Esto incluye la revisión del sistema hidráulico, la matriz de punzonado y el motor para garantizar su óptimo funcionamiento. Un mantenimiento adecuado puede prevenir la mayoría de los problemas de sobrecarga antes de que ocurran.

f. Capacitación del operador

Asegúrese de que los operadores estén debidamente capacitados en el uso y funcionamiento correctos de la punzonadora. Una capacitación adecuada puede reducir la probabilidad de ajustes y operaciones incorrectos, que son causas principales de sobrecarga.

5. Cómo prevenir la sobrecarga de la máquina punzonadora en el futuro

Prevenir futuros problemas de sobrecarga requiere una combinación de uso adecuado de la máquina, mantenimiento y capacitación del operador. Para evitar futuras sobrecargas, implemente las siguientes estrategias:

a. Instalar sistemas de protección contra sobrecargas

Algunas punzonadoras modernas incorporan sistemas de protección contra sobrecarga que las apagan automáticamente si exceden su capacidad nominal. Esta función protege tanto a la máquina como al operador de los riesgos asociados a la sobrecarga.

b. Utilice las herramientas adecuadas

Asegúrese de utilizar las matrices y herramientas de punzonado adecuadas para el material y la aplicación en cuestión. Usar herramientas incorrectas puede causar un esfuerzo innecesario en la máquina.

c. Actualizar el equipo

Si su punzonadora actual se sobrecarga con frecuencia, quizás sea hora de cambiarla por una más potente con mayor capacidad de tonelaje. Esto garantizará que la máquina pueda manejar la carga de trabajo sin sobrecargarse.

d. Monitoreo regular del desempeño

Supervise periódicamente el rendimiento de la punzonadora mediante métricas como la velocidad de corte, la precisión y el desperdicio de material. El seguimiento de estas métricas ayuda a identificar cualquier signo de sobrecarga antes de que se convierta en un problema grave.

Conclusión

La sobrecarga en las punzonadoras es un problema común pero grave que puede provocar tiempos de inactividad significativos, mayores costos de mantenimiento e incluso representar riesgos potenciales para la seguridad. Cuando una punzonadora se sobrecarga, puede provocar un desgaste excesivo de los componentes, provocando fallas prematuras en las piezas. Esto puede interrumpir el proceso de fabricación, lo que provoca retrasos en la producción y una disminución de la productividad general. Además, las condiciones de sobrecarga pueden incluso comprometer la seguridad de los operarios, exponiéndolos a condiciones peligrosas, incluyendo el riesgo de fallas mecánicas o accidentes.

Comprender las causas subyacentes de la sobrecarga en las punzonadoras es crucial para mitigar el problema. Las causas comunes incluyen ajustes incorrectos de la máquina, fuerza excesiva aplicada durante la operación o el uso de materiales que exceden la capacidad de la máquina. La sobrecarga también puede ocurrir debido a un mantenimiento inadecuado, como no lubricar las piezas móviles o no reemplazar componentes desgastados. Reconocer las primeras señales de sobrecarga, como ruidos inusuales, aumento de la vibración o rendimiento inconsistente, es esencial para abordar el problema antes de que cause daños significativos.

Para prevenir problemas de sobrecarga, los fabricantes deben priorizar el mantenimiento regular de sus punzonadoras. Esto incluye inspecciones rutinarias, garantizar una lubricación adecuada y reemplazar las piezas desgastadas con prontitud. Además, es fundamental asegurar que la máquina esté correctamente ajustada al material y la tarea específicos para prevenir la sobrecarga. Los operadores deben recibir la capacitación adecuada para reconocer y evitar las situaciones de sobrecarga, comprendiendo las limitaciones de la máquina y siguiendo los procedimientos operativos estándar. La selección adecuada del material también es fundamental para prevenir la sobrecarga, ya que los materiales demasiado gruesos o duros para la máquina pueden causar fácilmente tensión y daños.

Al seguir estas prácticas recomendadas (mantenimiento regular, configuración correcta de la máquina, selección adecuada de materiales y capacitación integral del operador), los fabricantes pueden prolongar la vida útil de sus punzonadoras, reducir el tiempo de inactividad y mejorar la eficiencia operativa. Invertir en medidas preventivas no solo protege la máquina, sino que también garantiza un proceso de producción más confiable y rentable, lo que, en última instancia, mejora el rendimiento general de la empresa.

Este artículo completo compara en profundidad estas dos máquinas en función de su estructura, rendimiento, rango de aplicación, capacidad de automatización, mantenimiento, rentabilidad y más.

Diseño estructural y calidad de construcción

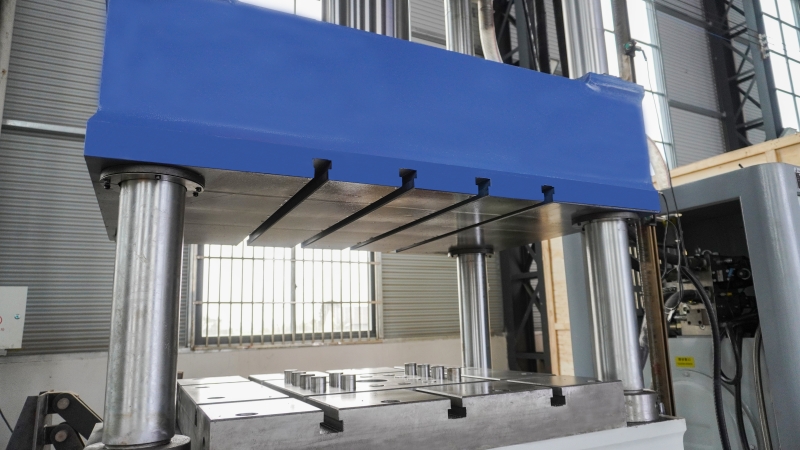

Prensa hidráulica Y32

La prensa hidráulica Y32 cuenta con una estructura vertical de cuatro columnas, reconocida por su excelente rigidez y equilibrio. Este diseño facilita operaciones de embutición profunda que requieren una distribución simétrica de la presión y una deformación mínima, incluso con cargas elevadas.

Ventajas estructurales:

- Las columnas de alta resistencia garantizan una fuerte resistencia a la distorsión del marco.

- Más adecuado para la formación de cavidades profundas y complejas.

- Estructura rígida ideal para componentes de precisión

Prensa hidráulica Y27

La serie Y27 está diseñada con una configuración de bastidor en C (columna única), lo que facilita la accesibilidad del operador y es ideal para trabajos de conformado de ligeros a moderados. Su diseño compacto facilita su integración en talleres pequeños.

Ventajas estructurales:

- El diseño frontal abierto permite cambios rápidos de matriz

- Compacto y eficiente para espacios de producción pequeños

- Más conveniente para sistemas de automatización periféricos

Descripción general de los parámetros técnicos

| Característica | Serie Y32 | Serie Y27 |

|---|---|---|

| Tipo de estructura | Cuatro columnas | Marco en C (columna única) |

| Rango de fuerza de presión | 100 – 2000 toneladas | 63 – 250 toneladas |

| Longitud del trazo | Hasta 1000 mm | Hasta 600 mm |

| Tamaño de la mesa | Personalizable | Formatos compactos estándar |

| Apertura durante el día | Hasta 1600 mm | Hasta 800 mm |

| Espesor de material adecuado | Láminas de grosor medio a grueso | Hojas finas a medianas |

| Panel de control | Pantalla táctil PLC + HMI | Interfaz básica del PLC |

| Huella de instalación | Requiere más espacio en el piso | Pequeño taller amigable |

Adecuación de la aplicación

Aplicaciones de la prensa hidráulica Y32

La prensa Y32 está optimizada para operaciones de conformado de alta precisión y alta exigencia. Es ideal para:

- Embutición profunda de autopartes como tanques de combustible, tapas de radiador y cárteres de aceite

- Utensilios de cocina grandes como fregaderos de cocina y ollas de acero inoxidable

- Formación de paneles para electrodomésticos y armarios

- Enderezamiento y troquelado donde se requiere uniformidad de alta presión

Ofrece una plataforma estable para aplicaciones de carrera larga y alta fuerza que involucran geometría de conformado compleja.

La prensa hidráulica Y32 es ideal para aplicaciones de alto rendimiento, garantizando una alta precisión en las operaciones de conformado. Proporciona una base sólida para aplicaciones con geometrías de conformado complejas, que requieren alta fuerza y gran recorrido. Esta prensa está optimizada para tareas que exigen fiabilidad y precisión en procesos de fabricación exigentes. Además, la prensa hidráulica Y32 está diseñada para ofrecer un rendimiento constante en entornos industriales rigurosos, satisfaciendo las exigencias de los requisitos de conformado complejos y de alta fuerza. Su diseño robusto y sus características avanzadas la convierten en un recurso valioso para diversos entornos de fabricación.

Aplicaciones de la prensa hidráulica Y27

La prensa Y27 es ideal para tareas más ligeras que requieren ciclos rápidos y cambios frecuentes de herramientas. Sus usos típicos incluyen:

- Perforación y recorte de piezas de chapa metálica

- Estampado y marcado de logotipos

- Conformado de trabajo ligero Para electrónica, elementos filtrantes y placas de identificación.

- Pruebas de moldes y trabajos de reparación

Es popular en pymes, departamentos de mantenimiento y talleres de producción por lotes.

La prensa Y32 está diseñada para tareas de conformado exigentes y de alta precisión. Se destaca por proporcionar una base robusta para geometrías de conformado complejas que requieren gran capacidad de fuerza y carrera. Por el contrario, la prensa Y27 está diseñada para operaciones más ligeras que requieren ciclos rápidos y ajustes frecuentes de las herramientas. Sus aplicaciones más comunes incluyen pequeñas y medianas empresas, unidades de mantenimiento e instalaciones de fabricación por lotes.

Automatización y personalización

Prensa Y32:

- Admite la integración con líneas de alimentación, alimentadores servo y cambiadores automáticos de matrices.

- Puede equiparse con sensores de presión, amortiguadores de matriz, eyectores y cortinas de seguridad.

- Adecuado para automatización de piezas complejas y conectividad de fábricas inteligentes

Prensa Y27:

- Compatible con herramientas de automatización ligera como transportadores y pedales.

- Configuraciones manuales más rápidas ideales para tiradas cortas

- Admite medidas de seguridad básicas y sensores opcionales.

Eficiencia energética y diseño de sistemas

Serie Y32:

- Equipados con sistemas de válvulas servohidráulicas o proporcionales

- Optimizado para ahorro de energía y control de presión constante

- La unidad hidráulica cuenta con reducción de ruido y control de temperatura del aceite.

Serie Y27:

- Configuración básica de la bomba hidráulica

- Rentable para aplicaciones intermitentes o de menor presión

- Mantenimiento más sencillo con circuitos hidráulicos simplificados

Facilidad de operación y ergonomía

| Criterios | Serie Y32 | Serie Y27 |

| Accesibilidad del operador | Cerrado, pero permite un funcionamiento seguro. | Marco en C completamente abierto para un fácil acceso |

| Tiempo de preparación del troquel | Moderado (depende de la complejidad) | Tiempos de configuración más cortos con marco abierto |

| Ergonomía | Diseñado para trabajos de precisión | Diseñado para la velocidad y la simplicidad |

| Interfaz de control | PLC avanzado multimodo | Interfaz de control fácil de aprender |

Mantenimiento y durabilidad

Ventajas del Y32:

- Componentes de alta resistencia adecuados para operaciones con un ciclo de vida prolongado

- Requiere mantenimiento programado para los sistemas hidráulicos y eléctricos.

- Diseñado para uso de alta carga con un desgaste mínimo

Ventajas del Y27:

- El diseño hidráulico simple garantiza un fácil mantenimiento

- Menor riesgo de fallos en entornos de trabajo ligero

- Las piezas de repuesto están ampliamente disponibles

Costo y retorno de la inversión

Serie Y32:

- Mayor inversión de capital

- Adecuado para líneas de producción de gran volumen con retorno de la inversión a largo plazo

- Ahorros en reducción de desechos, mayor precisión e integración de automatización.

Serie Y27:

- Inversión inicial más baja

- Implementación rápida y retorno de la inversión para talleres pequeños y medianos

- Ideal para talleres con diversas necesidades de productos y producción de lotes pequeños.

Caso práctico: Industria automotriz vs. industria de electrodomésticos

Fabricante de automóviles (Y32) Un proveedor automotriz de primer nivel eligió la serie Y32 para la embutición profunda de cárteres de aceite y tapas de batería de acero. Los requisitos clave fueron:

- Presión uniforme sobre matrices grandes

- Larga carrera operativa y longevidad de la herramienta

- Integración con un sistema de alimentación automático

El resultado fue un aumento de 35% en la productividad y una reducción de 25% en la tasa de desperdicio.

Fabricante de electrodomésticos (Y27) Un tamaño mediano aparato El productor seleccionó la prensa Y27 para gestionar operaciones rápidas como el grabado de logotipos y el recorte de hojas. Las principales consideraciones fueron:

- Tamaño compacto de la máquina

- Cambio rápido de herramientas

- Restricciones presupuestarias

El fabricante observó una mejora en la eficiencia del flujo de trabajo del 40% en un espacio limitado.

Cómo elegir el modelo adecuado para su taller

| Requisito | Modelo recomendado |

| Conformado profundo y de alto tonelaje | Serie Y32 |

| Espacio compacto y cambios rápidos | Serie Y27 |

| Integración de fábricas inteligentes | Serie Y32 |

| Operación manual y flexibilidad | Serie Y27 |

| Formación de carrera larga | Serie Y32 |

| Pruebas y reparación de moho | Serie Y27 |

Resumen: ¿Qué prensa hidráulica debería elegir?

Las prensas de las series Y32 e Y27 ofrecen un rendimiento confiable, pero atienden necesidades industriales muy diferentes:

- Elige el Y32 Si su enfoque está en la potencia, la precisión y la producción automatizada de gran volumen.

- Elige el Y27 Si su objetivo es flexibilidad, rentabilidad y diseño compacto.

HARSLE ofrece configuraciones personalizadas de prensas hidráulicas que se adaptan a su aplicación específica, garantizando la máxima eficiencia y durabilidad. Contacte con nuestro equipo de ingeniería para obtener asesoramiento profesional según sus objetivos de producción.

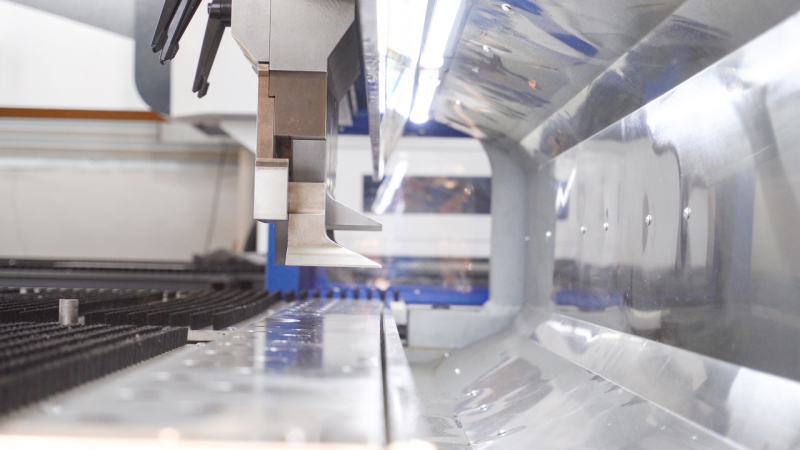

In this article, we will explore the top 5 advantages of using a CNC panel bender for sheet metal processing and provide a detailed breakdown of how this equipment can transform your production floor in both small and large manufacturing environments.

1. Unmatched Bending Speed and Productivity

One of the most significant benefits of CNC panel benders is their exceptional bending speed. Unlike conventional press brakes that require manual repositioning, realignment, and multiple tool changes, panel benders automate the entire bending sequence. The sheet metal is clamped in place, and a programmable bending blade performs each bend in sequence, rotating and adjusting automatically between bends.

This highly automated cycle dramatically reduces manual handling time, setup changes, and human error. CNC panel benders are particularly useful in Just-In-Time (JIT) production environments, where efficiency, speed, and repeatability are critical.

Real-World Benefits of Increased Speed:

- Shorter cycle times: Each panel is bent in seconds instead of minutes.

- Minimal downtime: Rapid changeover between part types with stored programs.

- High output: Suitable for high-volume production and custom batch runs alike.

- Quick setup: No need for frequent tool changes between bends.

Panel benders allow manufacturers to meet tight production schedules while delivering consistent results across hundreds or thousands of units.

2. Superior Bending Consistency and Accuracy

Precision is paramount in any sheet metal operation. A CNC panel bender ensures accurate and repeatable bending for every single part, regardless of operator skill level or production volume. Traditional press brakes, while versatile, depend significantly on the operator’s expertise and manual calibration for each job, which can introduce variation.

With a panel bender, computer-controlled settings manage every motion of the blade, clamps, and sheet rotation. Sensors detect material properties and automatically compensate for springback and deformation, maintaining tight tolerances throughout the production process.

Consistency That Boosts Quality:

- Integrated angle measuring systems: Guarantee accuracy for each bend.

- Material sensing: Adjusts for sheet thickness or hardness variations in real time.

- Error elimination: No more guesswork or trial-and-error.

- Perfect for symmetrical parts: High consistency in enclosures, drawer fronts, and cabinet panels.

This level of precision is especially valuable when manufacturing parts that must fit together perfectly or where cosmetic finish is important, such as in appliance or electrical enclosure production.

3. Greater Design Flexibility and Capability

CNC panel benders support a vast range of bending operations, offering flexibility that is difficult to achieve with traditional press brakes. Unlike press brakes that require individual tools for each bend angle or flange size, panel benders use universal tooling that can create different geometries without changeover.

With advanced programming software, manufacturers can produce complex panel shapes that include multiple radii, closed hems, shallow boxes, offset flanges, and variable-height returns—all within a single cycle.

What Makes Panel Benders Versatile:

- Universal tooling: Handles different geometries without changeover.

- Multi-radius forming: Ideal for panels with varying profiles.

- Pre-coated and sensitive materials: Panel benders avoid surface marring.

- Different materials: Works with stainless steel, aluminum, galvanized, and painted sheets.

By removing tooling restrictions, CNC panel benders encourage innovation in part design. Engineers can design more complex, functional, and aesthetic parts without being limited by forming capabilities.

4. Reduced Operator Dependency and Labor Costs

One of the biggest challenges in manufacturing today is the shortage of skilled labor. CNC panel benders offer a compelling solution by reducing reliance on highly trained press brake operators. Their intuitive software and automated material handling systems allow even entry-level staff to produce high-quality parts after minimal training.

This democratization of sheet metal bending reduces labor bottlenecks and allows your experienced team members to focus on higher-value tasks such as design, quality control, or maintenance.

How Panel Benders Reduce Operator Burden:

- Graphical programming interfaces: Easy to learn and use.

- Job storage: Save hundreds of part programs for quick recall.

- Minimal manual handling: Automatic clamping, rotation, and positioning.

- Ergonomic operation: Less lifting, reducing fatigue and injury risk.

In regions facing skilled labor shortages, or for companies expanding rapidly, panel benders make it easier to scale production while maintaining high quality.

5. Lower Total Cost of Ownership (TCO)

Although the upfront cost of a CNC panel bender may appear higher than that of a press brake, the overall total cost of ownership is often significantly lower. Faster production, fewer reworks, less scrap, and lower labor requirements all contribute to long-term cost savings.

Additionally, the universal tooling used in panel benders drastically reduces tooling inventory, change over time, and maintenance costs. Many panel benders are designed for 24/7 operation with minimal downtime, and remote diagnostics further help reduce service interruptions.

Cost-Effective Factors to Consider:

- Fewer scrap parts: Thanks to precision bending and reduced operator error.

- Lower rework costs: Higher consistency means less quality control intervention.

- Energy savings: Servo-electric drives consume less power than hydraulic systems.

- Fewer tool purchases: Universal tooling supports multiple bend types.

- Higher machine uptime: Built-in diagnostics and remote support minimize maintenance downtime.

The ROI on a CNC panel bender can often be realized within a few years, especially in facilities with high mix/low volume or JIT production models.

Additional Benefits: Safety, Sustainability, and Scalability

Beyond speed, precision, and cost, panel benders offer a number of secondary benefits that are increasingly important in modern manufacturing.

Safety Improvements:

- Fully enclosed bending area with safety interlocks

- Reduced manual handling lowers injury risk

- Automatic part ejection keeps operator hands away from tooling

Sustainability and Environmental Efficiency:

- Many machines feature energy-efficient motors and standby modes

- Lower waste and scrap rates reduce raw material usage

- Cleaner operation with electric drives (compared to hydraulic systems)

Scalable Growth Potential:

- Integrates easily into smart factory systems and MES platforms

- Supports robotic loading/unloading for lights-out manufacturing

- Software updates and upgrades extend machine lifespan

These extended benefits make panel benders a strong investment not just for present needs, but also for future automation and sustainability goals.

Applications Across Industries

CNC panel benders are used across a variety of sectors where precision sheet metal fabrication is essential:

- Electrical enclosures and switchgear panels

- HVAC units and ventilation systems

- Furniture components, including drawer fronts and cabinet doors

- Appliance housing such as washing machines and ovens

- Piezas de automóvil like battery trays and structural reinforcements

- Architectural elements including decorative panels and metal facades

Their versatility, speed, and precision make them valuable assets in both job shop environments and high-throughput automated lines.

Conclusión

If your business involves regular production of sheet metal panels, investing in a CNC panel bender can lead to measurable improvements in speed, accuracy, flexibility, and cost savings. By replacing manual operations and simplifying complex bend sequences, these machines empower manufacturers to stay competitive in an increasingly demanding market.

From lower scrap rates to faster lead times and reduced reliance on skilled labor, the benefits of CNC panel benders are significant and far-reaching. As product designs become more complex and customer expectations rise, upgrading to a CNC panel bender could be the key to unlocking new levels of efficiency, scalability, and profitability in your fabrication process.

Whether you’re expanding your production line, starting a new shop, or simply modernizing your capabilities, a CNC panel bender offers long-term advantages that make it one of the most worthwhile investments in sheet metal manufacturing today.

1. Metal Forming and Fabrication

Overview of Metal Forming

Hydraulic presses are widely used in the metalworking industry for various forming and fabrication processes. These include deep drawing, punching, stamping, forging, and bending. The hydraulic press’s ability to deliver controlled force over a longer stroke distance makes it ideal for working with metals, particularly in forming complex shapes without causing material stress or deformation.

Deep Drawing

One of the most common applications of hydraulic presses in metal forming is deep drawing. This process involves shaping a flat sheet of metal into a deep, hollow shape, such as car body panels or kitchen sinks. A hydraulic press exerts consistent pressure, allowing the material to flow evenly into the die. This process ensures a smooth, wrinkle-free finish, which is essential for producing high-quality metal parts.

Punching and Stamping

Prensas hidráulicas are also used for punching and stamping operations, where the press forces a punch through a sheet of metal to create holes or cut out specific shapes. This process is vital in the manufacturing of metal components for electronics, automotive parts, and appliances. The precision and force control offered by these machines make them ideal for high-volume production lines, ensuring each part meets exact specifications.

Advantages in Metal Forming

The versatility of hydraulic presses allows them to handle various metal thicknesses, from thin sheets to thick plates. Moreover, they provide better control over force, speed, and stroke, which reduces material waste and enhances the quality of the final product. Metal fabricators benefit from their ability to perform multiple operations, such as bending and cutting, in a single press cycle.

2. Automotive Industry

Automotive Part Manufacturing

The automotive industry relies heavily on hydraulic presses for manufacturing a wide range of parts, including chassis components, body panels, engine parts, and transmission housings. They are used to shape, trim, and assemble these components, ensuring they meet the high safety and performance standards required in the automotive sector.

Forming Car Body Panels

One of the most crucial applications of hydraulic presses in the automotive industry is the forming of large car body panels, such as doors, hoods, and fenders. These parts require precision forming to ensure proper fit and finish. They provide the necessary force to shape these panels while maintaining the integrity of the material, resulting in high-quality, durable parts.

Forging Engine and Transmission Components

In addition to sheet metal forming, hydraulic presses are also used in the forging of engine and transmission components. The high pressure exerted by the press allows for the deformation of metal billets into complex shapes, which are then used to manufacture engine blocks, crankshafts, gears, and other critical components. This process ensures the strength and durability needed for automotive parts that withstand high stresses and temperatures.

Advantages in the Automotive Industry

Hydraulic presses offer the automotive industry several advantages, including the ability to produce high-strength components with complex geometries. They also improve production efficiency by enabling faster cycle times and reducing the need for secondary operations. As automotive manufacturers continue to push for lighter, more fuel-efficient vehicles, they are playing a key role in the development of lightweight, high-strength materials such as aluminum and advanced high-strength steels.

3. Aerospace Industry

High-Precision Forming

The aerospace industry demands precision and quality in the manufacturing of parts, as even the smallest defect can lead to catastrophic failures in flight. They are used to form high-strength alloys, composites, and other materials into complex shapes required for aircraft components such as wings, fuselages, and landing gear.

Forming Lightweight Components

Hydraulic presses are particularly useful in the forming of lightweight materials like titanium and aluminum, which are essential for reducing the weight of aircraft and improving fuel efficiency. These materials can be difficult to work with using traditional mechanical presses, but hydraulic presses offer the precise control needed to form them without cracking or warping.

Composite Materials and Aerospace Parts

Hydraulic presses are also essential in the aerospace industry for forming composite materials, which are increasingly used for their strength-to-weight ratio and resistance to corrosion. Composites, such as carbon fiber-reinforced plastics, are used in various aircraft parts, including fuselage sections, wings, and interior components. The controlled pressure and slow application of force provided by hydraulic presses allow these materials to be shaped and cured without damaging their structural integrity.

Advantages in Aerospace

In the aerospace industry, where precision is paramount, hydraulic presses ensure that parts are manufactured to exact specifications with minimal variation. The flexibility of hydraulic systems also allows for adjustments during the forming process, reducing the risk of material defects and ensuring consistent quality. Furthermore, hydraulic presses can handle a wide variety of materials, making them an essential tool for the production of advanced aerospace components.

4. Plastics and Rubber Processing

Plastic Molding and Forming

Hydraulic presses play a significant role in the plastic and rubber processing industries, particularly in molding and forming operations. In plastic molding, hydraulic presses are used to shape plastic resins into various products, such as automotive components, packaging materials, and consumer goods. The controlled pressure exerted by the press ensures uniformity in the molded parts, reducing material waste and improving product quality.

Rubber Vulcanization

In rubber processing, hydraulic presses are used for vulcanization, a process that strengthens rubber by adding sulfur and applying heat and pressure. This process is critical for manufacturing durable rubber products, such as tires, seals, gaskets, and conveyor belts. The precise control of pressure and temperature provided by hydraulic presses ensures that the vulcanization process is carried out efficiently, producing high-quality rubber products that meet stringent industry standards.

Compression Molding

Another common application of hydraulic presses in the plastics and rubber industries is compression molding. This process involves placing a preheated material, such as plastic or rubber, into a heated mold cavity, where the press applies pressure to shape the material. Compression molding is used to produce a wide range of products, including automotive components, electrical housings, and appliance parts. Hydraulic presses are ideal for this process due to their ability to maintain consistent pressure and heat throughout the molding cycle.

Advantages in Plastics and Rubber

Hydraulic presses offer precise control over force and pressure, which is essential for producing high-quality plastic and rubber products. They also allow for faster production cycles, increasing output and reducing costs. Additionally, hydraulic presses can accommodate larger molds and more complex designs, making them ideal for the mass production of plastic and rubber components.

5. Electronics Industry

PCB Manufacturing

The electronics industry uses hydraulic presses in the production of printed circuit boards (PCBs), which are the foundation of most electronic devices. Hydraulic presses are used to laminate multiple layers of conductive material onto a substrate, creating the intricate circuits needed for modern electronics. The press ensures even pressure is applied across the entire PCB, resulting in high-quality, reliable boards that meet the strict standards of the electronics industry.

Potting and Encapsulation

Hydraulic presses are also used in the potting and encapsulation of electronic components, where the press helps to enclose delicate components in protective materials such as epoxy or silicone. This process ensures that electronic components are shielded from environmental factors such as moisture, dust, and heat, which could otherwise damage the device.

Advantages in Electronics

Hydraulic presses provide the electronics industry with the precision and control needed to produce high-quality components. Their ability to apply consistent pressure is essential for processes like PCB lamination and potting, where even slight variations can lead to defects. Furthermore, the flexibility of hydraulic presses allows them to be used in a variety of applications, from small-scale component manufacturing to large-scale production runs.

Conclusión

Hydraulic presses are integral to a wide range of industries, offering flexibility, precision, and control in various manufacturing processes. Whether it’s forming complex metal components in the automotive and aerospace sectors, molding plastic parts, or producing high-quality electronic components, hydraulic presses play a crucial role in ensuring that products meet stringent quality standards. Their versatility and adaptability have made them indispensable across industries, and as technology continues to advance, the applications for hydraulic presses are likely to expand even further.

En el acelerado mundo de la fabricación actual, la demanda de eficiencia, precisión y flexibilidad es mayor que nunca. Industrias como la automotriz, la aeroespacial y la metalurgia dependen de maquinaria avanzada para producir componentes de alta calidad, minimizando al mismo tiempo los costos y los tiempos de producción. Un equipo que ha transformado la fabricación moderna es la prensa plegadora CNC (Control Numérico Computarizado). Con la integración de la automatización, Prensas plegadoras CNC Están revolucionando la forma en que los fabricantes doblan, dan forma y procesan el metal, mejorando tanto la velocidad como la precisión.

El papel de la automatización en las prensas plegadoras CNC

La automatización en las prensas plegadoras CNC se refiere al uso de software avanzado, sensores y asistencia robótica para optimizar el proceso de plegado. La automatización puede gestionar diversos aspectos del funcionamiento de la prensa plegadora, como el cambio de herramientas, la manipulación de materiales e incluso los controles de calidad. Al minimizar la intervención humana, la automatización mejora la eficiencia y la consistencia de la producción.

Componentes clave de la automatización de la prensa plegadora CNC:

- Cambiadores de herramientas automatizados

Los cambiadores automáticos de herramientas permiten que la prensa plegadora alterne entre diferentes juegos de punzones y matrices sin intervención manual. Esto resulta especialmente beneficioso para fabricantes que trabajan con múltiples tipos de plegados o trabajos complejos que requieren diferentes herramientas. El cambio automático de herramientas reduce el tiempo de configuración y aumenta el tiempo de funcionamiento de la máquina, lo que se traduce en ciclos de producción más rápidos. - Brazos robóticos para manipulación de materiales

Los robots se integran cada vez más en los sistemas de prensas plegadoras CNC para gestionar la carga y descarga de material. Esto minimiza el trabajo manual, reduce el riesgo de lesiones laborales y permite una producción continua, incluso en turnos largos. Los brazos robóticos también garantizan la colocación precisa de las piezas, lo que contribuye a una mayor precisión. - Sensores y cámaras para control de calidad

Sensores y cámaras avanzados monitorizan cada operación de plegado para detectar cualquier defecto o inconsistencia en tiempo real. Los controles de calidad automatizados garantizan que cada pieza cumpla con las especificaciones requeridas sin necesidad de inspección manual, lo que se traduce en menos piezas rechazadas y una mayor calidad general. - Software de simulación de curvatura

La automatización de la prensa plegadora CNC incluye software que simula el proceso de plegado antes de comenzar. Esto ayuda a los operadores a visualizar el resultado final, predecir posibles errores y optimizar la secuencia de plegado para una mayor eficiencia. Estas simulaciones reducen el ensayo y error y ahorran un valioso tiempo de producción. - Ajustes automáticos del tope trasero

El tope trasero determina la posición de la chapa metálica durante el proceso de plegado. Los sistemas automatizados de tope trasero pueden reposicionar rápidamente la chapa según las especificaciones programadas, mejorando la velocidad y la precisión de cada plegado. Esta automatización también permite a la máquina manejar geometrías más complejas y múltiples plegados en una sola pieza.

Beneficios de la automatización de la prensa plegadora CNC

La automatización de las prensas plegadoras CNC ofrece importantes ventajas a los fabricantes, especialmente a aquellos que se centran en la producción a gran escala y los trabajos personalizados. A continuación, se presentan algunas ventajas clave:

1. Mayor velocidad de producción

Gracias a la automatización, las prensas plegadoras CNC pueden ejecutar plegados complejos a una velocidad mucho mayor que las máquinas manuales. Los cambiadores de herramientas automatizados, los robots de manipulación de materiales y la programación eficiente reducen el tiempo de preparación y permiten una producción continua sin necesidad de intervención frecuente del operador. Esto no solo aumenta la productividad, sino que también acorta los plazos de entrega, lo que permite a los fabricantes cumplir con plazos ajustados.

2. Precisión y exactitud mejoradas

La tecnología CNC ya ofrece una precisión excepcional, pero la automatización la lleva al siguiente nivel. Los sistemas automatizados eliminan el riesgo de error humano tanto en la manipulación de materiales como en la configuración de herramientas, garantizando que cada pliegue sea consistente y se ajuste a la tolerancia. Los sensores y los sistemas de monitorización en tiempo real detectan incluso las desviaciones más pequeñas y corrigen los problemas antes de que afecten al producto final.

3. Mayor flexibilidad

En industrias como la aeroespacial y la automotriz, donde las piezas personalizadas y la producción en lotes pequeños son comunes, la automatización permite que las prensas plegadoras CNC gestionen una amplia variedad de trabajos sin necesidad de una reconfiguración exhaustiva. Los cambiadores de herramientas automatizados y los topes traseros programables permiten transiciones rápidas entre diferentes diseños de piezas, lo que reduce el tiempo de inactividad entre trabajos y maximiza la utilización de la máquina.

4. Costos laborales reducidos

La automatización reduce la necesidad de mano de obra en tareas como la manipulación de materiales, la configuración de herramientas y la inspección. Esto no solo reduce los costos de mano de obra, sino que también permite que los operadores cualificados se concentren en tareas más complejas, como la programación y la supervisión de varias máquinas. La automatización robótica también puede funcionar de forma continua, aumentando la productividad sin gastos adicionales de mano de obra.

5. Seguridad mejorada

Una de las principales ventajas de la automatización es la reducción del trabajo físico necesario para operar la prensa plegadora. Los brazos robóticos manipulan materiales pesados, eliminando el riesgo de lesiones por levantamiento manual. Además, los sistemas automatizados garantizan cambios de herramientas más seguros y previenen accidentes causados por errores humanos, lo que aumenta la seguridad general del lugar de trabajo.

6. Mejor utilización de los recursos

Las prensas plegadoras CNC automatizadas optimizan el uso de materiales al minimizar el desperdicio. Los sistemas automatizados pueden calcular las secuencias de plegado más eficientes, reduciendo el material sobrante y garantizando que cada chapa se aproveche al máximo. Esto mejora la rentabilidad y reduce el impacto ambiental.

Cómo maximizar la eficiencia con la automatización de prensas plegadoras CNC

Si bien la automatización de las prensas plegadoras CNC ofrece un enorme potencial, los fabricantes deben implementarla estratégicamente para maximizar la eficiencia. Aquí tiene algunos consejos para ayudarle a sacar el máximo provecho de su sistema de prensa plegadora automatizada:

1. Invertir en formación integral

Aunque la automatización reduce la necesidad de intervención manual, los operadores aún necesitan comprender cómo programar y supervisar las máquinas. Ofrecer una capacitación integral garantiza que los operadores puedan aprovechar al máximo las capacidades de la máquina y solucionar cualquier problema que surja. La capacitación avanzada en programación CNC, configuración y mantenimiento de herramientas es esencial para el buen funcionamiento de las operaciones.

2. Optimizar las herramientas y la configuración

El uso de las herramientas adecuadas es fundamental para maximizar la eficiencia. Invierta en herramientas de alta calidad que puedan manejar diferentes tipos de plegados y materiales. Considere sistemas de herramientas modulares que se puedan cambiar o ajustar rápidamente mediante automatización. Además, el uso de software de programación sin conexión permite a los operadores preparar configuraciones sin detener la máquina, lo que aumenta su tiempo de funcionamiento.

3. Implementar mantenimiento preventivo

Las prensas plegadoras CNC automatizadas son muy fiables, pero requieren un mantenimiento regular para que funcionen a pleno rendimiento. Implemente un programa de mantenimiento preventivo que incluya inspecciones de los sistemas hidráulicos, sensores y herramientas. Las actualizaciones periódicas de software y las comprobaciones de calibración también garantizarán que la máquina mantenga su precisión a lo largo del tiempo.

4. Aproveche la monitorización de datos en tiempo real

Muchas prensas plegadoras CNC automatizadas incorporan sistemas de monitorización de datos que monitorizan el rendimiento de la máquina en tiempo real. Mediante el análisis de estos datos, los fabricantes pueden identificar ineficiencias, predecir posibles fallos de la máquina y optimizar los programas de producción. Los sistemas de monitorización también proporcionan información valiosa sobre el desgaste de las herramientas y el uso de material, lo que ayuda a reducir el desperdicio.

5. Integración con otros sistemas automatizados

Para aumentar aún más la eficiencia, considere integrar su prensa plegadora CNC con otros sistemas automatizados, como la manipulación robótica de materiales o una línea de producción totalmente automatizada. Esto permite transiciones fluidas entre las diferentes etapas de producción, reduciendo los cuellos de botella y garantizando un flujo de trabajo fluido.

El futuro de la automatización de las prensas plegadoras CNC

La automatización de las prensas plegadoras CNC está en rápida evolución, gracias a las nuevas tecnologías que mejoran tanto las capacidades de las máquinas como la eficiencia de la producción. Los avances futuros probablemente se centrarán en una mayor conectividad, donde las prensas plegadoras se integrarán en redes de fábricas inteligentes que utilizan dispositivos IoT (Internet de las Cosas) para comunicarse con otras máquinas y supervisar la producción general en tiempo real.

El software basado en IA también está en auge, con el potencial de optimizar las secuencias de plegado, la configuración de herramientas y el control de calidad con mínima intervención humana. A medida que mejoren los algoritmos de aprendizaje automático, las prensas plegadoras CNC serán aún más autónomas, capaces de tomar decisiones basadas en datos históricos y análisis predictivos.

Conclusión

Maximizar la eficiencia con la automatización de las prensas plegadoras CNC es crucial para los fabricantes que buscan mantenerse competitivos en el mercado actual. Al automatizar los cambios de herramientas, la manipulación de materiales, el control de calidad y más, las prensas plegadoras CNC pueden reducir significativamente los tiempos de producción, mejorar la precisión y reducir los costos de mano de obra. Para los fabricantes que buscan llevar su producción al siguiente nivel, adoptar la automatización en las prensas plegadoras CNC no es solo una opción, sino una necesidad.

Invertir en los sistemas automatizados, la capacitación y el mantenimiento adecuados permitirá a las empresas aprovechar al máximo los beneficios de la automatización, impulsando la productividad y la rentabilidad en los próximos años.

Understanding CNC Press Brakes

Press brakes are advanced machines used for bending and shaping metal sheets into desired forms. Unlike traditional press brakes, which require manual operation, CNC press brakes utilize computer programming to automate the bending process. This automation enables precise control over the bending angle, depth, and positioning, significantly enhancing productivity and accuracy.

Key Components of CNC Press Brakes

- Sistema de control: The brain of the CNC press brake, the control system interprets the programmed instructions and coordinates the machine’s movements.

- Bending Tooling: These include punches and dies, which come in various shapes and sizes to create different bends and profiles.

- Hydraulic or Electric Mechanism: CNC press brakes can be hydraulic or electric. Hydraulic systems are known for their power, while electric systems are recognized for their energy efficiency and precision.

- Calibre trasero: This component positions the metal sheet accurately before bending, ensuring consistency in production runs.

Advantages of CNC Press Brakes in Custom Fabrication

1. Precision and Consistency

One of the most significant advantages of CNC press brakes is their ability to provide precise and consistent bends. In custom fabrication, even minor discrepancies can lead to significant issues. CNC technology eliminates human error, ensuring that each piece meets exact specifications. This precision is particularly crucial in industries such as aerospace, automotive, and structural engineering, where tolerances can be extremely tight.

2. Flexibility in Design

CNC press brakes allow for complex geometries and custom shapes that would be challenging to achieve with manual methods. Fabricators can easily modify designs and quickly adapt to changing customer requirements. This flexibility is essential in custom fabrication, where each project may have unique specifications.

3. Increased Productivity

Automation significantly increases productivity in custom fabrication. CNC press brakes can perform multiple bends in a single cycle, reducing the time required to complete a project. This efficiency allows fabricators to take on more projects and meet tight deadlines without sacrificing quality.

4. Costos laborales reducidos

While the initial investment in CNC technology can be substantial, the reduction in labor costs can offset this expense over time. Fewer operators are needed to run CNC machines compared to manual press brakes, allowing companies to allocate their workforce more effectively.

5. Enhanced Safety Features

Modern CNC press brakes come equipped with safety features such as light curtains and emergency stop buttons. These enhancements protect operators and minimize the risk of accidents, making the workplace safer.

Applications of CNC Press Brakes in Custom Fabrication

CNC press brakes serve a wide range of applications in custom fabrication across various industries. Here are some notable examples:

1. Aerospace Industry

In the aerospace sector, precision is paramount. CNC press brakes are used to fabricate components such as brackets, supports, and frames that require exacting standards. The ability to create complex shapes with tight tolerances makes CNC press brakes indispensable in this field.

2. Automotive Manufacturing

The automotive industry relies heavily on custom fabrication for parts like chassis components, body panels, and interior fittings. Press brakes enable manufacturers to produce these parts efficiently and accurately, ensuring they meet safety and performance standards.

3. Architectural Fabrication

Custom fabrication in architecture often involves creating unique metal structures, railings, and decorative elements. CNC press brakes can bend metal sheets into intricate designs, allowing architects and designers to bring their visions to life.

4. Industrial Equipment

Manufacturers of industrial equipment often require custom components tailored to specific applications. Press brakes facilitate the production of brackets, covers, and housings with precision, enhancing the overall functionality of the equipment.

5. Sheet Metal Fabrication

In general sheet metal fabrication, CNC press brakes are used to create a variety of products, from HVAC ducts to enclosures. The versatility of CNC press brakes allows fabricators to handle diverse projects with ease.

The Custom Fabrication Process Using CNC Press Brakes

The custom fabrication process using CNC press brakes typically involves several key steps:

1. Design and Engineering

The first step in the custom fabrication process is designing the part. Engineers use CAD (Computer-Aided Design) software to create detailed drawings and specifications. This design is crucial for programming press brake.

2. Programming the Prensa plegadora CNC

Once the design is finalized, the next step is to program the CNC press brake. Operators input the specifications into the machine’s control system, including the bending sequence, angles, and tooling requirements. Advanced software can simulate the bending process, allowing for adjustments before actual production.

3. Material Preparation

The metal sheets are prepared for bending. This step may involve cutting the sheets to size and ensuring they are free from defects. Proper preparation is essential to achieve the desired results.

4. Bending Process

With everything set up, the metal sheet is placed in the press brake. The machine executes the programmed bending sequence, creating the desired shape. Operators monitor the process to ensure everything runs smoothly.

5. Quality Control

After bending, the finished parts undergo quality control checks to ensure they meet the specified tolerances. This step is critical in custom fabrication, where precision is non-negotiable.

6. Finishing Touches

Finally, any additional finishing processes, such as welding or surface treatment, are performed to complete the fabrication process.

Challenges in Custom Fabrication with CNC Press Brakes

While CNC press brakes offer numerous advantages, they are not without challenges. Understanding these challenges can help fabricators optimize their processes:

1. Initial Investment Costs

The cost of acquiring a press brake can be significant. Smaller businesses may struggle to justify this expense, particularly if they are just starting. However, the long-term benefits often outweigh the initial investment.

2. Skill Requirements

While CNC machines reduce the need for manual labor, they require skilled operators to program and maintain them. Finding qualified personnel can be a challenge, particularly in regions with a shortage of skilled workers.

3. Maintenance and Downtime

Like any machinery, CNC press brakes require regular maintenance to operate efficiently. Unexpected downtime due to mechanical issues can disrupt production schedules and lead to delays in fulfilling customer orders.

4. Material Limitations

Certain materials may present challenges when it comes to bending. Fabricators must understand the properties of the materials they work with to avoid issues such as cracking or warping during the bending process.

The Future of CNC Press Brakes in Custom Fabrication

As technology continues to evolve, so too will CNC press brakes. Several trends are shaping the future of these machines in custom fabrication:

1. Integration with Industry 4.0

The rise of Industry 4.0 is leading to greater connectivity and automation in manufacturing. CNC press brakes will increasingly integrate with other machines and systems, allowing for seamless data exchange and improved production workflows.

2. Advanced Materials and Techniques

The development of new materials and bending techniques will expand the capabilities of CNC press brakes. Fabricators will be able to work with a broader range of materials, including composites and advanced alloys.

3. Improved User Interfaces

Future CNC press brakes are likely to feature more intuitive user interfaces, making it easier for operators to program and control the machines. This will reduce the learning curve and improve overall efficiency.

4. Sustainability Initiatives

As sustainability becomes a priority in manufacturing, press brakes will be designed with energy efficiency in mind. Innovations that reduce power consumption and waste will be key to meeting environmental goals.

Conclusión

CNC press brakes play a crucial role in custom fabrication, providing precision, flexibility, and efficiency that traditional methods cannot match. As industries continue to demand customized solutions, the importance of CNC press brakes will only grow. By understanding their capabilities and potential challenges, fabricators can leverage this technology to enhance their operations and meet the evolving needs of their customers. The future of custom fabrication is bright, and press brakes will undoubtedly be at the forefront of this transformation.

1. Understanding Hydraulic Press Automation

Prensas hidráulicas have long been a staple in industries that require heavy-duty material processing, from metal forming to plastic molding. Traditional presses rely on manual or semi-automated controls, which can limit efficiency and introduce variability. However, automation takes these machines to the next level by integrating cutting-edge technology to handle repetitive tasks, optimize processes, and improve output accuracy.

Modern hydraulic press automation refers to the use of programmable systems, sensors, and robotics to control the operation of the press. Automated presses can be tailored to perform specific tasks with greater speed and consistency, making them ideal for high-volume production environments.

2. Benefits of Hydraulic Press Automation

Integrating automation into hydraulic presses offers numerous advantages that translate to improved operational efficiency:

a. Increased Production Speed

Automated hydraulic presses can operate faster than manually controlled machines, drastically reducing cycle times. Automation eliminates the need for human intervention in repetitive processes, allowing the machine to continuously operate at its maximum capacity.

b. Improved Accuracy and Precision

Automation reduces human error, resulting in more consistent and precise outputs. With programmable logic controllers (PLCs) and computer numerical control (CNC) systems, the press can be finely tuned to perform the same task with exact precision every time, which is critical in industries like aerospace, automotive, and electronics.

c. Enhanced Safety

Safety is a top priority in any manufacturing environment, and hydraulic press automation reduces the risk of injury by removing operators from hazardous areas. Automated presses are equipped with sensors, safety guards, and emergency stop functions that ensure safe operation and prevent accidents.

d. Lower Operational Costs

Although the initial investment in automation may be significant, it ultimately leads to reduced labor costs, fewer material wastages, and minimized downtime. Automated presses require less human intervention, which allows workers to focus on higher-value tasks, thus improving overall operational efficiency.

e. Better Data Collection and Monitoring

Automated systems allow for real-time data collection and monitoring of press operations. Sensors and software provide insights into performance metrics like cycle time, tonnage, and machine wear, enabling proactive maintenance and reducing the risk of unplanned downtime.

3. Key Components of Hydraulic Press Automation

To fully understand how automation maximizes efficiency in hydraulic presses, it’s important to break down the key components that make it possible.

a. Programmable Logic Controllers (PLCs)

PLCs are the brains behind hydraulic press automation. These digital computers control and monitor the machine’s operations by receiving input from sensors and executing pre-programmed instructions. PLCs can be programmed to manage various press functions, such as adjusting pressure, regulating cycle time, and ensuring safety protocols.

b. Human-Machine Interface (HMI)

An HMI is the visual interface through which operators can interact with the hydraulic press. Modern HMIs provide intuitive touchscreens where operators can monitor the machine’s status, configure settings, and access real-time data. The HMI simplifies machine control and enhances operator convenience.

c. CNC Systems

Computer Numerical Control (CNC) technology is often integrated with hydraulic presses to provide precise control over the machine’s movements and operations. CNC systems ensure that tasks like metal bending or stamping are performed with high accuracy, reducing waste and ensuring consistent results.

d. Sensors and Actuators

Sensors play a crucial role in monitoring machine performance, detecting anomalies, and ensuring the safety of the press. Common sensors include pressure transducers, proximity sensors, and limit switches. Actuators are responsible for converting electrical signals into mechanical movements, ensuring that the press operates smoothly and precisely.

e. Robotics and Material Handling Systems

Robotics can be integrated into hydraulic press automation to handle tasks such as loading and unloading materials. Automated material handling systems reduce manual labor, speeding up the production process and minimizing the risk of injury. Robots are particularly useful in high-volume production environments where consistency and speed are critical.

f. Safety Systems

Automated hydraulic presses come with advanced safety systems, including light curtains, safety mats, and emergency stop buttons. These systems prevent the press from operating when an operator is in a dangerous position and can halt the machine instantly in case of an emergency.

4. Steps to Maximizing Efficiency with Hydraulic Press Automation

To fully benefit from hydraulic press automation, manufacturers should implement the following strategies to optimize efficiency:

a. Evaluate Your Production Needs

The first step in maximizing efficiency is understanding your production requirements. Analyze your current operations to identify bottlenecks, inefficiencies, and opportunities for improvement. Consider factors such as production volume, material type, and cycle time when determining the level of automation required.

b. Choose the Right Automation Technology

Not all hydraulic presses are created equal, and the level of automation needed will vary depending on your specific application. For instance, a CNC press brake may be ideal for precision bending tasks, while a fully automated stamping press may be better suited for high-speed production. Work with your machine provider to select the right automation solution for your needs.

c. Integrate Data Monitoring and Analytics

Data collection and analysis are key to maximizing efficiency. Equip your automated press with sensors and software that can provide real-time data on performance metrics such as cycle time, pressure, and wear. Use this data to identify trends, optimize machine settings, and schedule preventive maintenance.

d. Train Operators on Automation Systems

Even though automated presses require less human intervention, operators still need to understand how to interact with the machine’s systems. Ensure that your team is properly trained on how to use the HMI, monitor the PLC, and troubleshoot common issues. Well-trained operators can quickly identify and resolve potential problems before they lead to costly downtime.

e. Prioritize Preventive Maintenance

Automation doesn’t eliminate the need for regular machine maintenance. In fact, with the increased speed and precision of automated presses, maintenance becomes even more critical. Implement a preventive maintenance schedule based on the data collected from sensors and analytics to reduce wear and tear on components and extend the lifespan of the press.

f. Focus on Safety

While automation improves safety by reducing human interaction with the press, it’s still essential to prioritize safety protocols. Regularly inspect and test safety systems, ensure that emergency stop functions are in place, and conduct periodic safety training for operators.

5. Common Challenges and Solutions in Hydraulic Press Automation

While hydraulic press automation brings numerous benefits, it also comes with its challenges. Understanding these challenges and knowing how to address them can further enhance efficiency.

a. High Initial Investment

Automating a hydraulic press can involve significant upfront costs, including the purchase of new equipment, software, and integration services. However, the long-term benefits of increased productivity, reduced labor costs, and improved output quality often outweigh the initial investment.

b. Integration with Existing Systems

For manufacturers with legacy equipment, integrating new automation technology with existing hydraulic presses can be challenging. Working with a knowledgeable automation provider can help ensure a smooth transition, and in some cases, retrofitting older machines with modern automation systems is a viable option.

c. Downtime During Implementation

Implementing automation may require temporary downtime as the new system is installed, programmed, and tested. Proper planning, training, and testing can minimize this downtime and ensure a smooth rollout.

6. The Future of Hydraulic Press Automation

As industries continue to embrace Industry 4.0, the future of hydraulic press automation looks promising. Innovations such as IoT integration, AI-driven predictive maintenance, and energy-efficient designs are poised to further enhance the performance of automated hydraulic presses. By adopting these technologies, manufacturers can stay ahead of the competition and continue to push the boundaries of efficiency.

Conclusión

Hydraulic press automation represents a significant leap forward for manufacturers seeking to maximize efficiency, improve output quality, and enhance safety. By integrating PLCs, CNC systems, sensors, and robotics into hydraulic presses, businesses can streamline their production processes and achieve higher levels of consistency and precision. Although there are challenges in implementing automation, the long-term benefits are clear. With proper planning, training, and maintenance, manufacturers can unlock the full potential of modern hydraulic press automation and position themselves for success in an increasingly competitive market.

In this article, we will explore the 10 most common hydraulic press errors and provide actionable tips on how to prevent them.

1. Incorrect Pressure Settings

The Issue:

One of the most frequent errors when using a prensa hidráulica is setting the incorrect pressure. Every application requires a specific amount of pressure to form, cut, or shape the material properly. Setting the pressure too high can damage both the machine and the workpiece, while too low a setting might result in incomplete or poor-quality results.

How to Avoid:

- Understand Material Requirements: Different materials require different levels of force. Familiarize yourself with the specifications of the material being used and adjust pressure settings accordingly.

- Use Proper Tools: Ensure that your hydraulic press has an accurate pressure gauge or digital readout that allows you to monitor and set the appropriate pressure.

- Perform Regular Calibration: Calibrate your press periodically to ensure that the pressure settings are accurate and reliable.

2. Insufficient Lubrication

The Issue:

Hydraulic presses rely on various moving parts to operate smoothly. Without proper lubrication, friction increases, leading to wear and tear, overheating, and eventual machine breakdowns. Lack of lubrication also accelerates the deterioration of seals and bearings.

How to Avoid:

- Follow the Manufacturer’s Guidelines: Always use the recommended lubricants as specified in the machine manual. Using improper lubricants can harm the machine components.

- Establish a Lubrication Schedule: Regularly check and apply lubricant to key moving parts such as the cylinder, ram, and guide rails.

- Monitor Lubricant Quality: Over time, lubricants can degrade and become contaminated with debris. Make it a point to check the condition of the lubricant and replace it as needed.

3. Improper Alignment of the Workpiece

The Issue:

Incorrect positioning or alignment of the workpiece is a common issue that can lead to uneven pressure distribution, inaccurate forming, or damage to the material. Misalignment increases the risk of breaking tools and causing machine failures.

How to Avoid:

- Use Positioning Tools: Employ fixtures, jigs, or positioning aids to ensure the workpiece is properly aligned before each operation.

- Double-Check Alignment: Make it a habit to visually inspect the workpiece alignment before activating the press.

- Train Operators: Train personnel on the importance of workpiece alignment and how to check for misalignment.

4. Overloading the Press

The Issue:

Exceeding the rated capacity or tonnage of a hydraulic press is a serious mistake that can result in significant damage to the press structure, cylinder, and hydraulic system. Overloading also poses a safety risk to operators.

How to Avoid:

- Know Your Machine’s Limits: Always be aware of the tonnage limits of your hydraulic press and avoid using it for tasks that require more force than it can safely deliver.

- Use Appropriate Presses for the Job: If a task consistently requires higher tonnage, consider using a different press that is designed for higher capacities.

- Install Load Monitors: Some hydraulic presses come with load sensors or overload protection systems. Use these features to prevent accidental overloading.

5. Hydraulic Fluid Contamination

The Issue:

Contaminated hydraulic fluid is one of the most common causes of hydraulic system failures. Dust, dirt, water, or metal particles can enter the hydraulic fluid, causing damage to internal components like pumps, valves, and seals.

How to Avoid:

- Use High-Quality Fluids: Always use the recommended hydraulic fluid grade and ensure it is from a trusted source.

- Regular Fluid Inspections: Check the hydraulic fluid for signs of contamination, such as cloudiness or particles. Change the fluid at regular intervals to keep it clean.

- Install Filters: Make sure the hydraulic system has efficient filters to trap contaminants before they reach critical components. Replace filters regularly as part of your maintenance routine.

6. Seal Wear and Failure

The Issue:

Seals in hydraulic systems are crucial for maintaining pressure and preventing fluid leaks. Over time, seals can wear out due to friction, heat, or chemical exposure. Seal failure leads to pressure loss, leaks, and inefficient press operation.

How to Avoid:

- Regular Seal Inspection: Inspect seals for signs of wear, cracking, or hardening. Replace them immediately if they show any deterioration.

- Use Compatible Seals: Ensure that the seals you use are compatible with the hydraulic fluid and operating temperature of the press.

- Prevent Overheating: Excessive heat accelerates seal degradation, so avoid running the press at extreme temperatures for prolonged periods.

7. Incorrect Tooling Setup

The Issue:

Setting up the wrong tooling for the job can lead to inaccurate results, material damage, and even press breakdowns. Incorrect die, punch, or fixture setup can strain the press beyond its intended capabilities.

How to Avoid:

- Match Tooling to the Task: Make sure the tooling used is appropriate for the material and the operation. Different tasks, such as bending or punching, require specific tooling configurations.

- Follow Manufacturer’s Instructions: Use the tooling recommended by the press manufacturer, and follow their setup instructions for optimal performance.

- Train Operators on Tooling: Proper training on tooling setup and changeover procedures can reduce setup errors and improve press performance.

8. Overheating the Hydraulic System

The Issue:

Hydraulic systems generate heat during operation, and without adequate cooling or ventilation, the system can overheat. Overheating leads to fluid degradation, increased wear on components, and ultimately machine failure.

How to Avoid:

- Monitor Operating Temperature: Use temperature sensors to monitor the hydraulic fluid temperature. If the press regularly overheats, consider installing a cooling system.

- Proper Ventilation: Ensure the press is in a well-ventilated area to allow heat to dissipate naturally. Avoid operating the press in overly hot environments.

- Regular Maintenance of Cooling Systems: If your hydraulic press has a built-in cooling system, regularly check and maintain it to ensure optimal performance.

9. Neglecting Preventative Maintenance

The Issue:

Skipping routine maintenance can lead to accumulated wear, undetected faults, and sudden machine breakdowns. This oversight often results in expensive repairs and extended downtime.

How to Avoid:

- Implement a Maintenance Schedule: Develop and follow a regular maintenance schedule that includes checking hydraulic fluid levels, inspecting seals, testing pressure settings, and cleaning the machine.

- Use Checklists: Keep a detailed checklist of maintenance tasks to ensure that nothing is overlooked during inspections.

- Document Issues: Record any recurring issues or necessary repairs to identify patterns and address underlying causes before they escalate.

10. Ignoring Operator Training

The Issue:

Untrained or under-trained operators are more likely to make critical errors that can lead to accidents, machine damage, and inefficient operation. Lack of training increases the risk of incorrect pressure settings, poor alignment, and mishandling of the equipment.

How to Avoid:

- Comprehensive Operator Training: Provide thorough training for all operators on machine functionality, safety protocols, and common troubleshooting procedures.

- Ongoing Skill Development: Offer refresher courses and additional training as needed, especially when new technologies or features are introduced to the press.

- Supervised Operation: For new operators, supervised operation is crucial until they become proficient in handling the hydraulic press independently.

Conclusión

Hydraulic presses are powerful tools that play a vital role in various industries, but they require proper handling and maintenance to function at their best. By being mindful of common errors such as incorrect pressure settings, improper alignment, and lack of lubrication, operators can prevent equipment failures and ensure safe, efficient operation. Implementing preventative maintenance, investing in operator training, and using high-quality hydraulic fluids are essential steps in prolonging the lifespan of your hydraulic press and avoiding costly repairs or downtime.

By addressing these 10 common errors, you can significantly improve the performance, safety, and longevity of your hydraulic press, ultimately benefiting your production line and your bottom line.

1. Assessing the Need for an Upgrade

Before diving into the specifics of upgrading, it’s crucial to assess whether your hydraulic press needs an upgrade or if it’s time for a complete replacement. Start by asking these questions:

- Is the machine meeting current production demands?