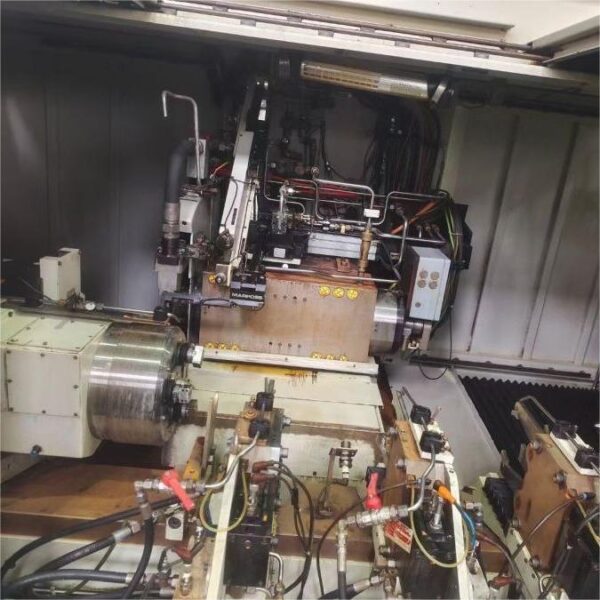

Used SMTCL YK2110 CNC Internal Circular Grinding Machine For Sale

| 무게 | 999 kg |

|---|---|

| 상태 |

90% 신규 |

| 기원 |

중국 |

| 지불 방법 |

LC ,티/티 |

| 가격 기간 |

EXW |

| 보증 |

1년 |

| 상표 |

오쿠마 |

| 모델 |

YK2110 |

| 기능 |

연마 |

| 제조 연도 |

2012 |

30

지금 이 제품을 보고 있는 사람들!

설명

A CNC internal circular grinding machine is a specialized machine tool used for precision grinding of internal cylindrical surfaces, such as bores, holes, and tubes, within a workpiece. This type of machine employs computer numerical control (CNC) technology to automate and control the grinding process, ensuring accurate and repeatable results. Here’s a comprehensive description of the components and features typically found in a CNC internal circular grinding machine:

- Machine Structure: A CNC internal circular grinding machine,The machine’s structure is designed to provide stability and rigidity during the grinding process, minimizing vibrations and ensuring precision. The construction may include a heavy base, column, and grinding head assembly.

- CNC 제어 시스템: A CNC internal circular grinding machine,The heart of the machine is the CNC control system, which interprets programming instructions and generates commands for precise tool movement. Operators input parameters through a user-friendly interface, allowing for accurate control over the grinding process.

- Internal Grinding Spindle: A CNC internal circular grinding machine features a high-precision grinding spindle that rotates an abrasive grinding wheel. The spindle can be adjusted for speed, rotation direction, and angular positioning, enabling accurate grinding of internal cylindrical surfaces.

- Linear Motion System: Linear guides, ball screws, and servo motors facilitate controlled movement of the grinding wheel and workpiece along various axes, ensuring accurate positioning.

- Workhead and Chuck: The workhead holds the workpiece and can be equipped with various types of chucks or fixtures to securely grip the workpiece during grinding. The chuck may rotate the workpiece or allow for precise angular adjustments.

- Dressing System: Some machines feature an automatic dressing system that maintains the shape and condition of the grinding wheel for consistent performance. Properly dressed grinding wheels ensure accurate and efficient grinding.

- 냉각수 시스템: A coolant system is essential for cooling the grinding process, reducing friction and heat generation, and evacuating grinding debris. This maintains the quality of the workpiece and prolongs the life of the grinding wheel.

- Wheel Balancing System: Balancing systems help ensure uniform grinding results by minimizing vibration and chatter that can affect the quality of the ground surface.

- Measuring and Feedback Systems: Some advanced machines include measuring probes or sensors that provide real-time feedback on the workpiece dimensions during grinding. This information can be used to adjust the grinding process for optimal results.

- 안전 설비: Safety measures, including protective enclosures, emergency stop buttons, and interlocks, are essential to protect operators and prevent accidents during operation.

- Programming and Simulation: Many CNC internal circular grinding machines offer programming software and simulation capabilities that allow operators to create, edit, and verify grinding programs before execution.

- Connectivity: Connectivity options enable the transfer of design files, remote monitoring of machine performance, and receiving maintenance alerts.

- Accuracy and Repeatability: Designed for high precision, these machines offer accurate and repeatable results within tight tolerances, ensuring consistent quality in the finished workpieces.

상품평 (0)

“Used SMTCL YK2110 CNC Internal Circular Grinding Machine For Sale”의 첫 상품평을 남겨 주세요 명확하다

상품평

아직 상품평이 없습니다.