Used VIGERT L600AW Machining Center For Sale

| 상표 |

비게르트 |

|---|---|

| 상태 |

95% 새로운 |

| 기원 |

중국 |

| 모델 |

L600AW |

| 제조 연도 |

2015 |

| 가격 기간 |

EXW |

| 기능 |

머시닝센터 |

| 지불 방법 |

티/티 |

| 보증 |

1년 |

10개 재고

15

지금 이 제품을 보고 있는 사람들!

설명

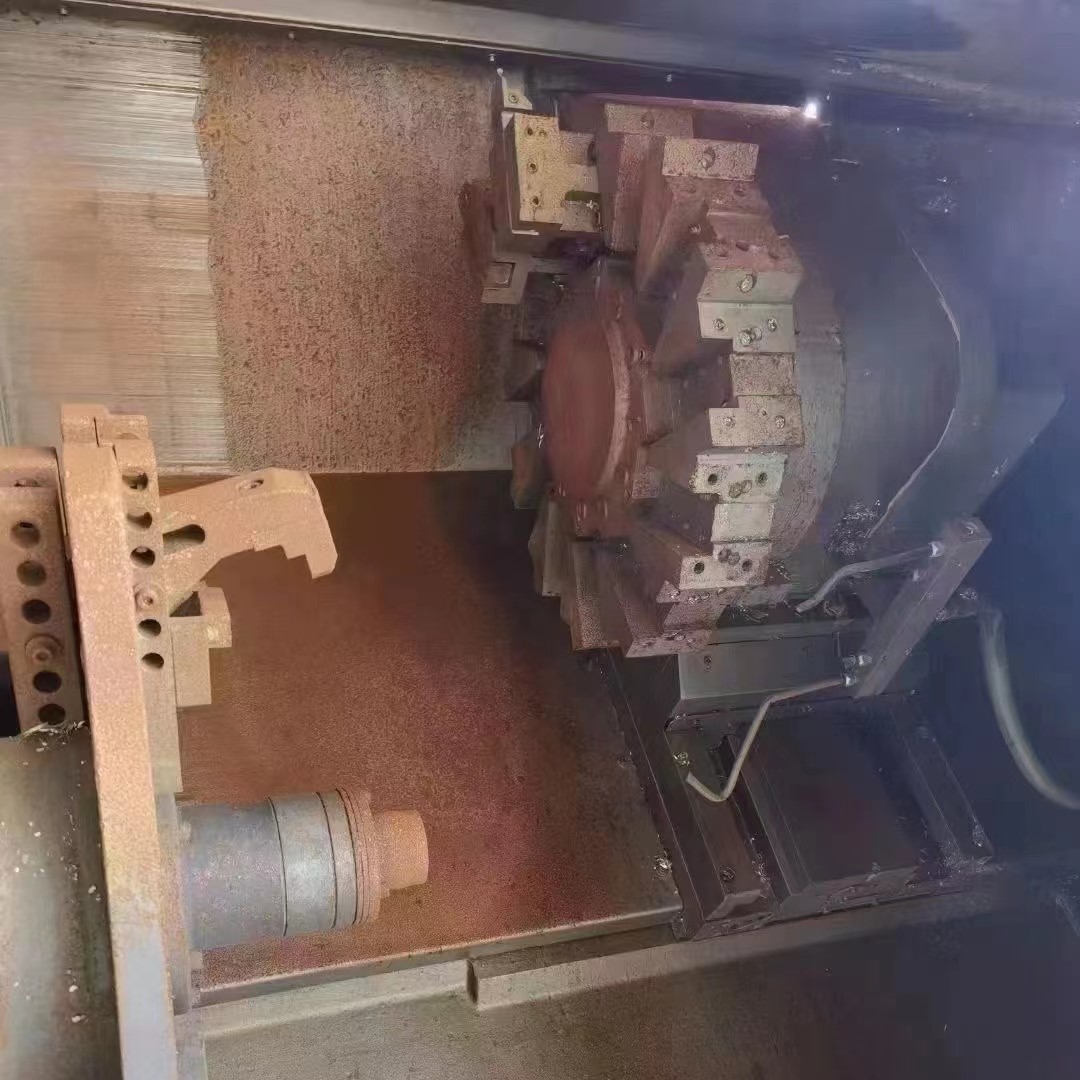

Used VIGERT L600AW Machining Center

A Used VIGERT L600AW Machining Center, also known as a CNC machining center, is a computer-controlled machine tool that can perform various machining operations with high precision and automation. It’s a versatile and powerful tool used in manufacturing and production environments to efficiently create complex parts and components. Here are the key features and aspects of a machining center:

- 컴퓨터 수치 제어(CNC): Similar to a CNC lathe, a machining center is controlled by a computer program that guides the tooling and workpiece movements to achieve the desired machining operations.

- 다축 가공: Machining centers often have multiple axes of movement, including three or more linear axes (X, Y, Z) and rotational axes (A, B, C). This enables the machining of intricate and complex geometries.

- 자동 공구 교환기(ATC): Used VIGERT L600AW Machining Centers are equipped with automatic tool changers that allow for rapid and automated changing of cutting tools, improving efficiency and reducing downtime.

- 다재: Machining centers can perform a wide range of machining operations, such as milling, drilling, tapping, contouring, boring, and more, all in a single setup.

- Rigid Structure and High Precision: The machine’s structure is designed to be rigid and stable, providing high precision and accuracy during machining operations.

- Integration with CAD/CAM Systems: Machining centers are often integrated with Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software, enabling seamless transfer of designs and automated programming.

- Tool Holding Systems: Machining centers use various tool-holding systems, such as collets, chucks, and automatic tool clamping systems, to secure cutting tools during machining.

- 작업 고정 장치: Different workholding devices, such as vises, clamps, and fixtures, are used to secure the workpiece in place and ensure stability during machining.

- High-Speed Machining (HSM): Machining centers can achieve high spindle speeds and feed rates, allowing for faster material removal and increased productivity.

- Coolant Systems: Machining centers are equipped with coolant systems to lubricate and cool the cutting tools and workpiece during machining, enhancing tool life and surface finish.

- 모니터링 및 피드백 시스템: Advanced machining centers often include sensors and monitoring systems to track tool wear, detect errors, and provide real-time feedback for process optimization.

- Production Efficiency: Used VIGERT L600AW Machining Centers significantly improve production efficiency by reducing setup times, minimizing manual intervention, and optimizing tool paths for efficient material removal.

Used VIGERT L600AW Machining Centers are essential tools in modern manufacturing, playing a critical role in producing precise and complex components across various industries, including aerospace, automotive, medical devices, and more.

상품평 (0)

“Used VIGERT L600AW Machining Center For Sale”의 첫 상품평을 남겨 주세요 명확하다

상품평

아직 상품평이 없습니다.