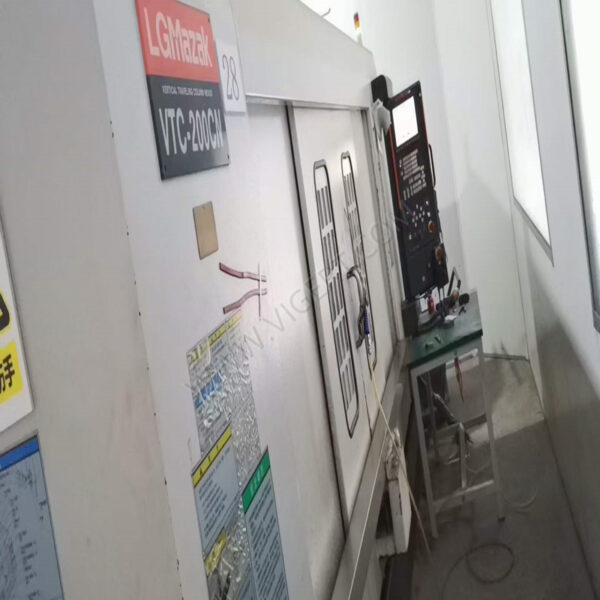

DAHE Used V1500 Advanced CNC Machining Center For Sale

| 무게 | 999 kg |

|---|---|

| 상태 |

85% 신규 |

| 제조 연도 |

2018 |

| 기원 |

중국 |

| 지불 방법 |

LC ,티/티 |

| 상표 |

다헤 |

| 가격 기간 |

EXW |

| 기능 |

갈기 |

| 보증 |

1년 |

| 모델 |

V1500 |

The V1500 Advanced CNC Machining Center is a cutting-edge industrial machine that redefines precision machining operations. Engineered for exceptional accuracy, efficiency, and versatility, this CNC machining center integrates state-of-the-art technology and features that set new standards for advanced manufacturing. Here’s a comprehensive description of its attributes:

CNC 기술: V1500 Advanced CNC Machining Center. The V1500 CNC Machining Center is equipped with advanced Computer Numerical Control (CNC) technology that empowers operators to program intricate machining operations with unparalleled precision. This CNC system enables automation, accuracy, repeatability, and the creation of complex shapes and profiles.

High-Performance Capability: V1500 Advanced CNC Machining Center. Engineered for outstanding performance, the V1500 CNC Machining Center excels in terms of speed, power, and adaptability. It’s optimized to handle a wide range of machining tasks with remarkable efficiency.

Generous Work Envelope: V1500 Advanced CNC Machining Center. The “V1500” designation highlights its generous work envelope. With a substantial working area of 1500mm (or an appropriate dimension), this machining center can accommodate a diverse range of workpieces for various industries and applications.

Innovative Features: V1500 Advanced CNC Machining Center. The CNC machining center incorporates innovative features that differentiate it from conventional machines. These could encompass advancements like multi-axis machining capabilities, real-time tool condition monitoring, adaptive machining algorithms, and integration with the Industrial Internet of Things (IIoT) for data-driven insights.

Enhanced Precision and Repeatability: Advanced technology ensures precise machining operations, minimizing errors and ensuring consistent results across various workpieces. This level of precision is crucial for industries demanding tight tolerances and superior machining quality.

Automation and Programming: The advanced CNC system empowers operators to program and automate complex machining sequences, reducing manual interventions, enhancing efficiency, and minimizing the risk of errors.

사용자 친화적인 인터페이스: The V1500 CNC Machining Center features an intuitive user interface, potentially incorporating touchscreens and streamlined programming and monitoring interfaces that enhance setup and operation.

Adaptive Machining: The machining center may incorporate adaptive machining techniques that continuously adjust cutting parameters based on real-time sensor data or material variations. This ensures optimal machining outcomes even as conditions change during the process.

안전 설비: Advanced safety features are integrated into the CNC machining center’s design to ensure operator protection during operation. These could include automated tool monitoring, collision detection, and emergency stop mechanisms.

Connectivity and Data Analytics: The CNC machining center might offer connectivity options for real-time data exchange and analysis. This involves transmitting production data to centralized systems for monitoring, analysis, and continuous process optimization.

다재: The V1500 Advanced CNC Machining Center is designed for versatility, making it suitable for industries such as aerospace, automotive, energy, and more. Its advanced features and capabilities make it adaptable to various applications.

상품평

아직 상품평이 없습니다.