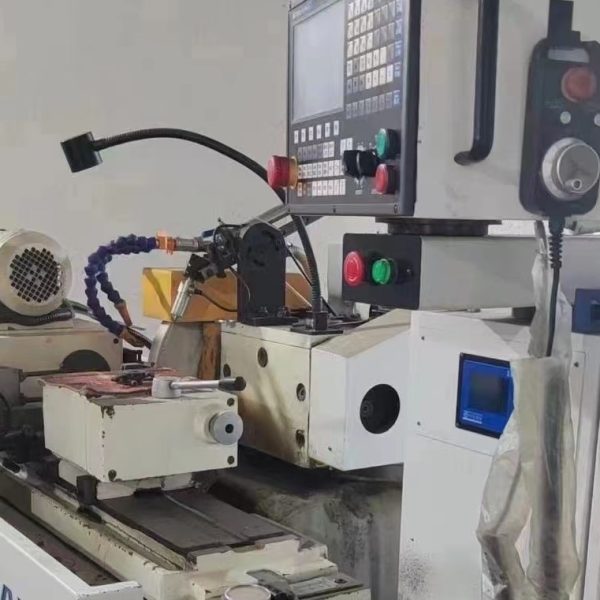

Máquina de retificação de precisão SEEDTEC 1632AHD usada à venda

| Marca |

VIGERT |

|---|---|

| Doença |

85% Novo |

| Função |

Esmerilhamento |

| Modelo |

1632AHD |

| Origem |

Taiwan da China |

| Ano MFG |

2020 |

| Forma de pagamento |

T / T |

| Termo de preço |

EXW |

| garantia |

Um ano |

Máquina de retificação de precisão 1632AHD

Precision grinding machines are used in manufacturing processes to achieve high levels of accuracy and surface finish in the machining of various materials. These machines use abrasive wheels to remove material from a workpiece to create precise shapes, sizes, and surface qualities. They are commonly used in industries such as aerospace, automotive, electronics, and tool manufacturing.

Here are some general features you might expect to find in the “1632AHD Precision Grinding Machine” or a similar precision grinding machine model:

- High Precision Operation: On the basis of 1632AHD Precision Grinding Machine . Precision grinding machines are designed to achieve extremely tight tolerances and surface finish requirements.

- Controle CNC: On the basis of 1632AHD Precision Grinding Machine . Many modern precision grinding machines are equipped with computer numerical control (CNC) technology, allowing for precise control over grinding operations.

- Multiple Axes: Precision grinding machines often have multiple axes of movement, which can include X, Y, Z, and rotary axes, enabling complex grinding operations.

- Automatic Tool Changers: Some models may come with automatic tool changers for different types of grinding wheels or tools, allowing for versatile grinding processes.

- Parâmetros programáveis: Operators can input various parameters such as grinding wheel speed, feed rate, depth of cut, and dressing frequency to customize the grinding process.

- Wheel Dressing: Precision grinding machines might have features for automatic or manual wheel dressing, ensuring the grinding wheel remains sharp and accurate.

- Sistemas de refrigeração: Many precision grinding machines are equipped with coolant systems to control heat generated during grinding and to improve surface finish.

- Workpiece Fixturing: The machine’s design might include various options for securely holding and positioning the workpiece during grinding.

- Monitoring and Feedback: CNC grinding machines often offer monitoring and feedback systems to ensure consistent grinding results and to detect any anomalies.

- Características de segurança: Like any machinery, precision grinding machines have safety features such as emergency stop buttons, interlocks, and protective enclosures.

Por que escolher o VIGERT?

VIGERT é um revendedor profissional de máquinas para usinagem de metais na China há muitos anos, nossas produções foram vendidas para mais de 100 países no mundo!

Avaliações

Ainda não há avaliações.