Used GLEASON P90 CNC Gear Milling Machine For Sale

| Peso | 999 kg |

|---|---|

| Dimensões | 1000 × 3000 cm |

| Marca |

GLEASON |

| Doença |

90% Novo |

| Função |

Fresamento de engrenagens |

| Ano MFG |

2016 |

| Modelo |

P90 |

| Origem |

Suíça |

| garantia |

Um ano |

| Termo de preço |

EXW |

| Forma de pagamento |

T / T |

10 em estoque

A GLEASON P90 CNC Gear Milling Machine is a specialized machine tool used in the process of gear manufacturing. It’s designed to produce gears by the process of gear hobbing, which is a type of milling process for creating cylindrical gears. Gear hobbing machines are essential in the production of a wide range of gears used in various industries, including automotive, aerospace, heavy machinery, and more.

Here are the key components and features of a GLEASON P90 CNC Gear Milling Machine:

- Hobbing Tool: The hobbing tool is a cutting tool with multiple cutting edges. It is the primary tool used to shape the gear teeth during the hobbing process.

- Workpiece: The workpiece is the gear blank or gear blank material on which the gear teeth are cut. It is mounted on the machine and rotated during the hobbing process.

- Hob Arbor: The hob arbor holds the hobbing tool securely and provides the necessary rotation to perform the cutting.

- Hob Head: The hob head houses the hob arbor and controls its movement, allowing for precise positioning and depth of cut during the hobbing process.

- Workholding Fixture: P90 CNC Gear Milling Machine. The workholding fixture securely holds the workpiece in place during the hobbing process, ensuring accurate gear cutting.

- Feed Mechanism: The feed mechanism controls the rate at which the hobbing tool engages with the workpiece, determining the depth and speed of the gear tooth cutting.

- Rotation Mechanism: This mechanism controls the rotational movement of the workpiece, enabling the hobbing tool to cut the gear teeth.

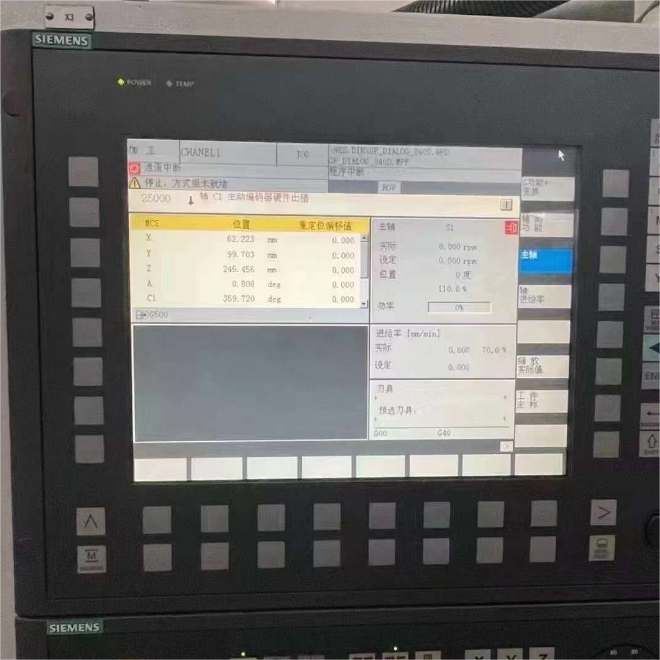

- Controlador CNC: Modern gear hobbing machines often incorporate a CNC controller that allows for precise control over the cutting process, including speed, feed, depth of cut, and other parameters.

- Sistema de refrigeração: A coolant system is used to cool the cutting area during the hobbing process, preventing overheating and prolonging tool life.

The gear hobbing process involves the hobbing tool gradually cutting into the workpiece to create gear teeth. As the workpiece rotates and the hobbing tool traverses along its length, it generates the desired gear profile.

GLEASON P90 CNC Gear Milling Machines are versatile and capable of producing a wide range of gears, from small gears to large and complex ones. They are essential in achieving high precision and productivity in gear manufacturing, making them a vital component in the production of machinery and mechanical components.

Por que escolher o VIGERT?

VIGERT é um revendedor profissional de máquinas para usinagem de metais na China há muitos anos, nossas produções foram vendidas para mais de 100 países no mundo!

Avaliações

Ainda não há avaliações.