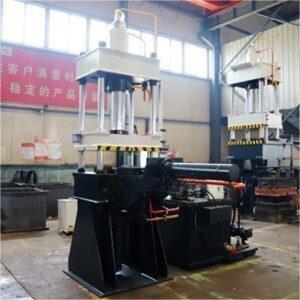

Used VIGERT 200T Vertical Die Casting Machine For Sale

| Peso | 999 kg |

|---|---|

| Dimensões | 800 × 350 × 200 cm |

| Marca |

VIGERT |

| Doença |

85% Novo |

| Função |

Fundição sob pressão |

| Ano MFG |

2019 |

| Modelo |

200 toneladas |

| Origem |

China |

| Forma de pagamento |

LC ,T / T |

| Termo de preço |

EXW |

| garantia |

Um ano |

VIGERT 200T Vertical Die Casting Machine is a specialized industrial equipment used in the process of die casting,which is a manufacturing process for producing metal parts by forcing molten metal into a mold cavity under high pressure. Here’s a description of its key features and functionalities:

- Tonelagem: The “200T” in the name refers to the machine’s clamping force, measured in tons. In this case, indicating its ability to exert considerable pressure to keep the mold closed during the casting process.

- Processo de fundição sob pressão: Die casting machines like the VIGERT 200T Vertical Die Casting Machine use a process where molten metal is injected into a die (metal mold) under high pressure. The metal solidifies within the mold cavity to form the desired shape of the final product. Die casting is commonly used for producing complex, high-quality metal parts with tight tolerances.

- Sistema hidráulico: The VIGERT 200T Vertical Die Casting Machine typically utilizes a hydraulic system to operate the clamping unit and injection system. Hydraulic power is essential for applying the high pressure required to force the molten metal into the mold cavity and to keep the mold closed during solidification.

- Unidade de Injeção: A máquina é equipada com uma unidade de injeção composta por um reservatório de metal fundido, um êmbolo e uma luva de injeção. A unidade de injeção é responsável por injetar quantidades precisas de metal fundido na cavidade do molde sob pressão e velocidade controladas.

- Controle de temperatura: Temperature control systems are crucial in die casting machines to ensure proper solidification of the molten metal and to prevent defects such as porosity and shrinkage. The VIGERT 200T Vertical Die Casting Machine machine may feature advanced temperature control systems for both the molten metal and the mold.

- Automação e Controle: Modern die casting machines like the 200T often come equipped with advanced automation and control systems for precise operation and monitoring. These systems may include programmable logic controllers (PLCs), human-machine interfaces (HMIs), and sensors for monitoring parameters such as pressure, temperature, and cycle time.

- Versatilidade: The VIGERT 200T Vertical Die Casting Machine is capable of producing a wide range of metal parts, from small and intricate components to large and complex shapes. Its high clamping force and precision control make it suitable for various industries, including automotive, aerospace, electronics, and consumer goods.

Overall, the VIGERT 200T Vertical Die Casting Machine is a powerful and versatile piece of equipment designed for high-volume production of metal parts with consistent quality and dimensional accuracy. Its robust construction, advanced features, and automation capabilities make it an essential tool in modern manufacturing processes.

Por que escolher o VIGERT?

VIGERT é um revendedor profissional de máquinas para usinagem de metais na China há muitos anos, nossas produções foram vendidas para mais de 100 países no mundo!

Avaliações

Ainda não há avaliações.