Used HARSLE W12 8X2000 Rolling Machine For Sale

| Вес | 999 кг |

|---|---|

| Габариты | 1000 × 3000 см |

| Марка |

HARSLE |

| Состояние |

99% Новый |

| Функция |

прокатка |

| MFG Год |

2020 |

| Модель |

HARSLE W12 8X2000 |

| Источник |

Китай |

| Способ оплаты |

ЛК ,Т / Т |

| Срок действия цены |

EXW |

| Гарантия |

Один год |

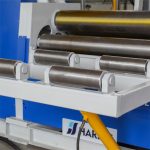

A HARSLE W12 8X2000 Rolling Machine, also known as a rolling mill or rolling press, is a sophisticated piece of industrial equipment designed to shape and manipulate metal materials through a series of continuous processes. The primary function of a rolling machine is to reduce the thickness of a metal sheet or shape it into a desired form by passing it through a pair of rotating rolls. These rolls exert pressure on the metal, causing it to deform plastically and conform to the shape of the rolls.HARSLE W12 8X2000 Rolling Machine

The basic components of a rolling machine include:HARSLE W12 8X2000 Rolling Machine

- Rolls: These are cylindrical or semi-cylindrical metal components that rotate in opposite directions. They are typically made of hardened steel or other durable materials to withstand the high pressures and temperatures generated during the rolling process.HARSLE W12 8X2000 Rolling Machine

- Rolling Stand: The rolls are mounted on a frame called the rolling stand, which provides support and alignment. The stand may be fixed or adjustable to accommodate different thicknesses and shapes of metal.

- Drive Mechanism: A motor and gearbox system provide the necessary power to rotate the rolls at controlled speeds. The drive mechanism may also include gears, belts, or chains to transmit motion from the motor to the rolls.

- Rolling Passes: The rolling process is divided into multiple passes, each of which gradually reduces the thickness of the metal. In some cases, intermediate annealing or heat treatment steps may be incorporated between passes to relieve stress and improve the formability of the metal.HARSLE W12 8X2000 Rolling Machine

- Система охлаждения: To prevent overheating of the rolls and maintain consistent operating temperatures, a cooling system is often integrated into the rolling machine. This may involve circulating water or other cooling fluids through channels within the rolls or the rolling stand.

- Система контроля: Modern rolling machines are equipped with advanced control systems that monitor and regulate various parameters such as roll speed, pressure, temperature, and thickness reduction. These systems ensure precise control over the rolling process and enable operators to achieve the desired product specifications with high accuracy.

Rolling machines are widely used in industries such as steel manufacturing, automotive, aerospace, construction, and metal fabrication. They are capable of producing a wide range of products including sheets, plates, bars, rods, tubes, and structural shapes in various sizes and thicknesses. The versatility and efficiency of rolling machines make them indispensable tools for shaping and transforming metal materials into finished products with the required mechanical properties and dimensional accuracy.

Почему выбирают VIGERT?

VIGERT - профессиональный продавец подержанных металлообрабатывающих станков в Китае на протяжении многих лет, наша продукция продается более чем в 100 странах мира!

Отзывы

Отзывов пока нет.