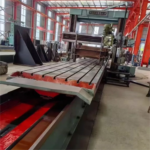

Продаётся б/у машина для литья под давлением LK DC280

| Вес | 999 кг |

|---|---|

| Габариты | 800 × 350 × 200 см |

| Марка |

ЛК |

| Состояние |

85% Новый |

| Функция |

Литье под давлением |

| MFG Год |

2019 |

| Модель |

DC280 |

| Источник |

Китай |

| Способ оплаты |

ЛК ,Т / Т |

| Срок действия цены |

EXW |

| Гарантия |

Один год |

An DC280 Die Casting Machine is a specialized industrial equipment used in the process of die casting, which is a manufacturing process for producing metal parts by forcing molten metal into a mold cavity under high pressure. Here’s a description of its key features and functionalities:

- Тоннаж: The “DC280 ” in the name refers to the machine’s clamping force, measured in tons. In this case, the machine has a clamping force of 1200 tons, indicating its ability to exert considerable pressure to keep the mold closed during the casting process.

- Процесс литья под давлением: Die casting machines like the DC280 Die Casting Machine use a process where molten metal is injected into a die (metal mold) under high pressure. The metal solidifies within the mold cavity to form the desired shape of the final product. Die casting is commonly used for producing complex, high-quality metal parts with tight tolerances.

- Гидравлическая система: The DC280 Die Casting Machine typically utilizes a hydraulic system to operate the clamping unit and injection system. Hydraulic power is essential for applying the high pressure required to force the molten metal into the mold cavity and to keep the mold closed during solidification.

- Блок впрыска: Машина оснащена инжекционным узлом, состоящим из резервуара для расплавленного металла, плунжера и впрыскивающей втулки. Инжекционный узел отвечает за подачу точного количества расплавленного металла в полость формы под контролируемым давлением и скоростью.

- Контроль температуры: Temperature control systems are crucial in die casting machines to ensure proper solidification of the molten metal and to prevent defects such as porosity and shrinkage. The DC280 Die Casting Machine machine may feature advanced temperature control systems for both the molten metal and the mold.

- Автоматизация и управление: Modern die casting machines like the DC280 often come equipped with advanced automation and control systems for precise operation and monitoring. These systems may include programmable logic controllers (PLCs), human-machine interfaces (HMIs), and sensors for monitoring parameters such as pressure, temperature, and cycle time.

- Универсальность: The DC280 Die Casting Machine is capable of producing a wide range of metal parts, from small and intricate components to large and complex shapes. Its high clamping force and precision control make it suitable for various industries, including automotive, aerospace, electronics, and consumer goods.

Overall, the DC280 Die Casting Machine is a powerful and versatile piece of equipment designed for high-volume production of metal parts with consistent quality and dimensional accuracy. Its robust construction, advanced features, and automation capabilities make it an essential tool in modern manufacturing processes.

Почему выбирают VIGERT?

VIGERT - профессиональный продавец подержанных металлообрабатывающих станков в Китае на протяжении многих лет, наша продукция продается более чем в 100 странах мира!

Отзывы

Отзывов пока нет.