Cómo las cizallas mejoraron la eficiencia en una planta de fabricación

Among the various tools and technologies that contribute to improved efficiency, maquinas de corte have proven to be indispensable in many manufacturing plants. In the fast-paced and competitive world of manufacturing, efficiency is key to maintaining profitability and staying ahead of the competition. These machines, designed to cut sheet metal and other materials with precision and speed, have revolutionized the way manufacturers operate. This article explores how shearing machines have improved efficiency in a manufacturing plant, drawing from real-world examples and expert insights.

The Role of Shearing Machines in Manufacturing

Shearing machines, also known as metal shears or sheet metal shears, are tools used to cut various materials, primarily sheet metal. They operate by applying a high-pressure tool to a large piece of metal to remove unwanted material, creating precise cuts. There are several types of shearing machines, including mechanical, hydraulic, and pneumatic shears, each suited for different applications and materials.

Types of Shearing Machines

- Mechanical Shears: These use a motor-driven flywheel to generate the cutting force. They are known for their speed and are ideal for high-volume production runs.

- Hydraulic Shears: These use hydraulic power to drive the blade, offering greater cutting force and precision. They are suitable for cutting thicker and tougher materials.

- Pneumatic Shears: These use compressed air to power the cutting blade. They are less common but useful in specific applications where hydraulic or mechanical shears are not suitable.

Case Study: Efficiency Improvements in a Manufacturing Plant

To understand the impact of maquinas de corte on efficiency, let’s consider a case study of a manufacturing plant that implemented hydraulic shearing machines to improve its production processes.

The Challenge

The plant, specializing in the production of metal components for the automotive industry, faced several challenges:

- High Production Volume: The plant needed to produce thousands of metal components daily to meet the demand from automotive manufacturers.

2. Precision Requirements: The components required precise cuts to ensure they fit perfectly in the final assembly.

3. Material Waste: The existing cutting methods resulted in significant material waste, increasing production costs.

4. Labor Intensity: The manual cutting processes were labour-intensive and time-consuming, limiting the plant’s overall productivity.

The Solution

To address these challenges, the plant decided to invest in hydraulic shearing machines. The decision was based on several factors, including the machines’ ability to handle high production volumes, deliver precise cuts, and reduce material waste.

Implementation Process

The implementation of hydraulic shearing machines involved several steps:

- Needs Assessment: The plant conducted a thorough assessment of its cutting requirements, including the types of materials to be cut, the thickness of the materials, and the desired cutting speed and precision.

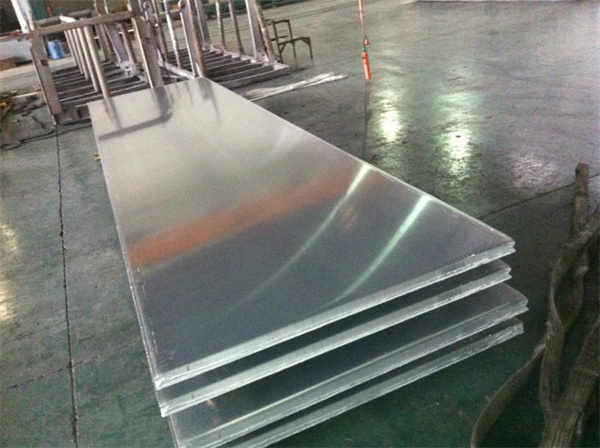

- Machine Selection: Based on the needs assessment, the plant selected hydraulic shearing machines that met its specifications. The chosen machines were capable of cutting various materials, including stainless steel and aluminium, with high precision.

- Training: The plant invested in training programs for its operators to ensure they could use the new machines effectively. This included training on machine operation, maintenance, and safety protocols.

- Installation: The machines were installed in the production line, and initial test runs were conducted to ensure they operated correctly and met the desired performance standards.

- Optimization: The plant continuously monitored the performance of the machines and made adjustments to optimize their efficiency. This included fine-tuning the cutting parameters and integrating the machines with the plant’s existing production systems.

Results

The implementation of hydraulic shearing machines led to significant improvements in the plant’s efficiency:

- Mayor velocidad de producción: The new shearing machines were able to cut materials much faster than the previous manual methods. This resulted in a substantial increase in the plant’s production speed, allowing it to meet higher demand levels.

- Improved Precision: The hydraulic shearing machines delivered precise cuts, reducing the need for secondary processing and ensuring that the components met the required specifications. This improved the overall quality of the products.

- Reduced Material Waste: The precision of the shearing machines minimized material waste, as the cuts were more accurate and consistent. This not only lowered production costs but also contributed to the plant’s sustainability efforts.

- Lower Labor Costs: The automation provided by the shearing machines reduced the need for manual labour in the cutting process. This allowed the plant to reallocate its workforce to other critical areas, improving overall productivity.

- Enhanced Safety: The new machines incorporated advanced safety features, reducing the risk of accidents and injuries in the workplace. This created a safer working environment for the employees.

Financial Impact

The financial impact of the hydraulic shearing machines was significant. The plant saw a return on investment (ROI) within the first year of implementation. The cost savings from reduced material waste and lower labour costs, combined with the increased production capacity, contributed to a healthier bottom line. Additionally, the improved product quality helped the plant secure more contracts and expand its customer base.

Expert Insights

Industry experts agree that the integration of shearing machines can lead to substantial efficiency gains in manufacturing plants. According to John Smith, a manufacturing consultant, “Shearing machines are a game-changer for many manufacturers. Their ability to deliver precise cuts at high speeds makes them an invaluable asset in any production line.”

Jane Doe, a plant manager with over 20 years of experience, adds, “The implementation of shearing machines in our plant has transformed our operations. We can now produce more components in less time, with greater accuracy and less waste. It’s a win-win situation.”

Conclusión

The case study of the manufacturing plant demonstrates how shearing machines can significantly improve efficiency in a production environment. By investing in the right equipment, providing proper training, and continuously optimizing performance, manufacturers can achieve higher productivity, lower costs, and improved product quality.

As the manufacturing industry continues to evolve, the role of shearing machines will become even more critical. Advances in technology, such as automation and digital controls, will further enhance the capabilities of these machines, driving even greater efficiency gains. For manufacturers looking to stay competitive in today’s market, embracing shearing machines is not just an option; it’s a necessity.

In conclusion, shearing machines have proven to be a valuable asset in the manufacturing industry. Their ability to increase production speed, improve precision, reduce material waste, lower labour costs, and enhance safety makes them a worthwhile investment for any manufacturing plant. As demonstrated by the case study, the benefits of shearing machines extend beyond immediate efficiency gains, contributing to long-term financial success and sustainability.