23 puntos importantes de las máquinas plegadoras

A máquina de freno de prensa is a specialized tool used in metal fabrication to bend and shape sheet metal and plates. It operates by applying force to a piece of metal to deform it, creating bends, angles, and forms according to the desired specifications. Press brake machines are a crucial part of modern manufacturing processes, offering precision and versatility in creating a wide range of metal components and products.

Types of Press Brake Machines

Press brake machines come in various types, each designed to cater to specific bending needs, materials, and production requirements. These machines serve as the workhorses of modern metal fabrication, providing versatility, precision, and efficiency in shaping sheet metal and plates. Here are the main types of press brake machines:

Mechanical Press Brake: This traditional type of press brake employs a mechanical linkage system to generate the bending force. Mechanical press brakes are known for their simplicity, reliability, and cost-effectiveness. They are suitable for simple bending tasks and can handle a range of materials. However, they may have limitations in terms of precision and speed compared to more modern types.

Hydraulic Press Brake: Hydraulic press brakes use hydraulic cylinders to generate the bending force. They offer higher precision, control, and power compared to mechanical press brakes. Hydraulic systems allow for greater flexibility in adjusting bending speed, force, and stroke length, making them suitable for a wide range of bending applications, from simple to complex.

Servo-Electric Press Brake: These press brakes utilize servo-electric motors to control the bending process. They offer exceptional accuracy, repeatability, and energy efficiency. Servo-electric press brakes are well-suited for applications that demand high precision, such as industries that require fine-tuned bends and intricate shapes. They also offer faster setup times and reduced maintenance compared to hydraulic systems.

CNC Press Brake: Computer Numerical Control (CNC) press brakes are equipped with advanced control systems and software. These machines allow for automated and programmable bending operations. CNC press brakes are highly versatile, capable of handling complex bending sequences and producing consistent results across large batches. They often integrate with CAD/CAM systems, enabling seamless translation of design data into precise bending instructions.

Each type of press brake machine has its own strengths and limitations, making them suitable for different production scenarios. Factors such as the type of material, the complexity of bends required, precision demands, production volume, and budget considerations influence the choice of press brake type. As technology continues to advance, press brake machines are evolving to offer higher levels of automation, customization, and energy efficiency, further enhancing their role in modern manufacturing processes. Whether it’s a simple mechanical press brake, a versatile hydraulic machine, a precision servo-electric model, or a sophisticated CNC system, press brake machines remain indispensable tools in shaping the metal components that drive various industries forward.

Components and Structure of Press Brake Machines

The components and structure of press brake machines are crucial elements that determine their performance, precision, and versatility in metal bending and forming processes. Press brake machines’ design is meticulously engineered to accommodate the forces involved in bending while providing a stable platform for accurate and consistent results. Understanding the key components and structure sheds light on the complexity behind this essential tool in modern metal fabrication.

At the heart of a press brake machine is its main frame and construction materials. The main frame is typically made from heavy-duty steel, cast iron, or a combination of both to ensure rigidity and stability during bending operations. This robust construction minimizes vibrations and deflections caused by the immense forces exerted during bending, guaranteeing precision and repeatability.

The hydraulic or mechanical power system is another vital component. In hydraulic press brakes, hydraulic cylinders generate the force required for bending. These cylinders are powered by hydraulic pumps that deliver hydraulic fluid to create pressure, which in turn moves the ram (upper beam) downward to perform the bend. Mechanical press brakes, on the other hand, employ a mechanical linkage system that converts rotational motion into linear force for bending. The choice between hydraulic and mechanical systems depends on factors like bending force requirements, speed, and precision.

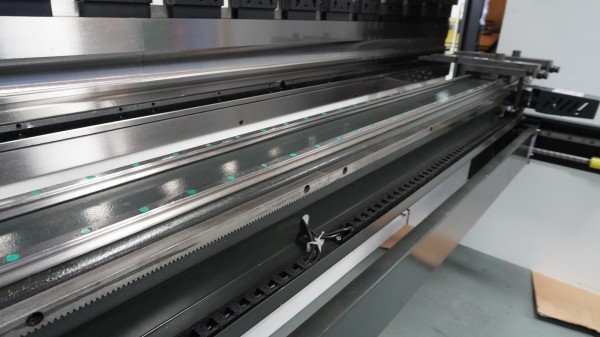

The bed and ram structure defines the working area of the press brake. The bed provides a flat and level surface where the sheet metal or plate rests during bending. The ram, equipped with the tooling, moves vertically to bend the material against the bed. The tooling consists of punches and dies that determine the final shape of the bend. These tooling components come in various sizes and profiles to accommodate different bending requirements.

A back gauge system is integral for accurate and repeatable bends. This system consists of adjustable fingers or stops that position the material precisely relative to the tooling. Advanced press brake machines incorporate CNC-controlled back gauges, enabling automation and the creation of complex bending sequences with minimal manual intervention.

The control panel and user interface provide the operator with control over various parameters, such as bend angle, bend length, and force. Modern press brake machines often feature intuitive touchscreens and software interfaces that allow operators to program, simulate, and execute bending operations with ease. CNC-enabled machines take this a step further by offering the capability to store and recall multiple bending programs.

The interplay of these components within the press brake’s structure is what empowers this machine to transform flat sheets of metal into intricate forms, angles, and bends. The careful engineering of the frame, the power system’s efficiency, the precision of the tooling, and the sophistication of the control system all contribute to the press brake’s ability to deliver consistent and high-quality results across a range of metal bending applications.

Working Principles of Press Brake Machines

Press brake machines are at the forefront of modern metal fabrication, enabling precise bending and forming of sheet metal and plates. These machines operate based on a set of well-defined principles, combining mechanics, hydraulics, and control systems to transform raw materials into intricate shapes and angles. Understanding the working principles of press brake machines sheds light on the intricate dance of forces and mechanisms that underlie their remarkable capabilities.

Bending Process Overview: At its core, the bending process involves applying force to a piece of metal to deform it and create a bend. This is achieved by pressing a punch (an upper tool) against a die (a lower tool), with the material placed between them. As the punch descends, it presses the material against the die, causing it to bend along the die’s contour. The degree of bending depends on factors such as the punch’s shape, the die’s profile, the material’s properties, and the applied force.

Role of Hydraulic Systems: In hydraulic press brake machines, hydraulic systems play a pivotal role in generating the force needed for bending. Hydraulic cylinders, powered by hydraulic pumps, create hydraulic pressure that moves the ram (upper beam) downward. This downward motion of the ram applies the bending force to the material. The hydraulic fluid’s pressure is distributed evenly across the hydraulic system, ensuring a controlled and uniform bending action.

Ram Movement and Control: The ram’s movement is carefully controlled to achieve accurate and consistent bends. The control system, often computer-based, regulates the movement of the ram. It allows operators to set parameters such as bending angle, bend length, and force. As the ram descends, the material comes into contact with the die and starts bending. The control system ensures that the ram stops at the desired position, achieving the precise angle specified by the operator.

Interaction Between Tooling, Material, and Bending Force: The tooling, comprising punches and dies, is essential in determining the bend’s final shape. The material’s thickness, elasticity, and yield strength also influence the bending process. The bending force must be calculated carefully to ensure that it is sufficient to deform the material without causing permanent damage. Excessive force can lead to over-bending or even material failure, while insufficient force results in incomplete bends.

Importance of Proper Alignment and Positioning: Accurate alignment and positioning of the material are critical for achieving precise bends. Press brake machines are equipped with back gauge systems that help position the material correctly relative to the tooling. These back gauges can be manually adjusted or CNC-controlled, allowing for consistent and repeatable setups. Proper alignment ensures that the bending action occurs exactly where intended, resulting in uniform and symmetrical bends.

Press brake machines epitomize the marriage of engineering and precision in metal fabrication. Their working principles harmonize mechanical force, hydraulic power, tooling precision, and control system sophistication to transform raw metal into precisely bent and shaped components. These machines exemplify the intersection of artistry and science, enabling manufacturers to create products that push the boundaries of design while adhering to the demands of accuracy and repeatability. As technology continues to advance, the working principles of press brake machines will evolve, driving innovation and shaping the future of metal fabrication.

Types of Bends Achievable

Press brake machines are versatile tools that can achieve a wide array of bends in sheet metal and plates. These machines are vital to industries ranging from automotive to construction, enabling the creation of complex components with precision and consistency. The types of bends achievable with press brake machines are as diverse as the industries they serve, each with its unique characteristics and applications.

Air Bending: Air bending is a common bending technique where the material is bent using only a fraction of the machine’s maximum force. The material’s bend angle is determined by the interaction between the punch, die, and material properties. Air bending is versatile and allows for a range of bend angles without requiring specialized tooling.

Bottoming: Bottoming, also known as coining, involves applying maximum force to bend the material against the die until it contacts the bottom of the die. This technique produces precise and consistent bends with sharp angles. Bottoming is often used when high accuracy and tight tolerances are required.

Coining: Coining is a controlled and precise bending technique that results in a highly accurate bend with minimal spring back. The punch presses the material into the die cavity, creating a sharp bend angle and well-defined features. Coining is ideal for applications that demand strict dimensional accuracy and a polished finish.

V-Die Bending: V-die bending utilizes a V-shaped die and punches to achieve bends with a sharp angle. The material is pressed into the V-shaped cavity, creating a bend that resembles a V. V-die bending is particularly useful for achieving consistent bends on materials of varying thicknesses.

U-Bending: U-bending creates a U-shaped bend by using a punch and die with curved surfaces. The punch presses the material into the U-shaped die, forming a smooth and uniform bend. U-bends are often employed in applications where aesthetic appeal and structural integrity are crucial.

Hemming: Hemming involves folding the edges of a sheet of metal over itself to create a clean and safe edge. Hemming not only enhances the appearance of the component but also adds rigidity to the edge, reducing the risk of injury. This technique is commonly used in automotive and appliance manufacturing.

Doblado descentrado: Off-center bending involves creating bends that are not aligned with the center of the material. This technique is used to achieve specific design requirements or to create complex shapes that cannot be achieved with traditional centered bends. Off-center bending requires precise tooling and control to maintain accuracy.

Each of these bending techniques requires a deep understanding of material properties, tooling selection, and machine parameters. Press brake operators must consider factors such as material thickness, bend angle, tooling geometry, and the machine’s tonnage capacity to achieve the desired results. The versatility of press brake machines allows manufacturers to produce a wide range of components, from simple brackets to intricate architectural details, all while maintaining the highest standards of precision and quality. As industries continue to evolve, press brake technology will play a vital role in shaping the future of metal fabrication and design.

Press brake machines stand as indispensable pillars in the world of modern metal fabrication and manufacturing. Their significance resonates across various industries, from automotive and aerospace to construction and beyond. These machines serve as the conduit through which flat sheets of metal are transformed into complex, precisely bent components that form the foundation of countless products and structures.