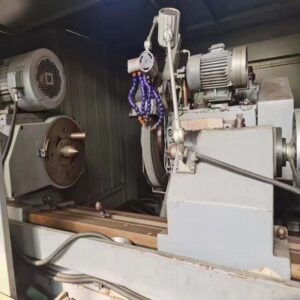

Rectificadora VIGERT MGK1450 usada en venta

| Peso | 999 kg |

|---|---|

| Condición |

90% Nuevo |

| Año MFG |

2010 |

| Origen |

porcelana |

| Método de pago |

LC ,T / T |

| Término de precio |

EXW |

| Garantía |

Un año |

| Modelo |

MGK1450 |

| Marca |

VIGERT |

| Función |

Molienda |

Este producto ya está en su lista de solicitud de cotización.

28

¡Gente mirando este producto ahora!

Descripción

MGK1450 Grinding Machine. The process involves rotating the workpiece against the grinding wheel, resulting in material removal through abrasion.

MGK1450 Grinding Machine. Here’s a more detailed description of the key components and features of a typical grinding machine:

- Muela:MGK1450 Grinding Machine. The grinding wheel is the primary tool used for grinding. It is usually made of abrasive particles bonded together with a bonding material like resin, vitrified, or metal. Different types of wheels are used for various applications, such as cutting, rough grinding, and finishing.

- Pieza de trabajo:MGK1450 Grinding Machine. The workpiece is the material being machined or ground. It is secured in the machine and rotated against the grinding wheel during the grinding process.

- Workholding Device: This device holds and secures the workpiece in place during the grinding operation. It ensures stability and accuracy in the grinding process.

- Grinding Machine Table: The table is where the workpiece is placed or mounted. It can be a stationary table or a rotating table, depending on the type of grinding machine.

- Grinding Head or Spindle: The grinding head houses the grinding wheel and is responsible for its rotation. The spindle can be vertical or horizontal, and it provides the necessary power and movement for the grinding operation.

- Grinding Wheel Guard: A safety feature that protects the operator from debris and sparks generated during the grinding process.

- Wheel Dresser: This tool is used to true the surface of the grinding wheel, ensuring it is in the correct shape and sharpness for efficient grinding.

- Sistema de refrigerante: Many grinding machines use a coolant to prevent overheating of the workpiece and the grinding wheel. This helps in extending the life of the grinding wheel and achieving better surface finishes.

- Sistema de control: Modern grinding machines often have computer numerical control (CNC) systems that allow for precise control of the grinding process, including parameters like feed rate, depth of cut, and spindle speed.

- Feed Mechanism: The feed mechanism controls the movement of the grinding wheel or workpiece relative to each other, determining the material removal rate and the quality of the finish.

- Power Supply: Provides the necessary electrical power to drive the grinding wheel, workholding devices, and other components of the machine.

Valoraciones (0)

Sé el primero en valorar “Used VIGERT MGK1450 Grinding Machine For Sale” Cancelar la respuesta

Sobre VIGERT

¿Por qué elegir VIGERT?

VIGERT es un distribuidor profesional de máquinas para trabajar metales usadas en China desde hace muchos años, ¡nuestras producciones se han vendido a más de 100 países en el mundo!

Productos relacionados

Used REISHAUER RG500 Grinding Machine For Sale

Este producto ya está en su lista de solicitud de cotización.

Rectificadora cilíndrica OKAMOTO OGM-330 usada en venta

Este producto ya está en su lista de solicitud de cotización.

Rectificadora CNC SUPERTEC GM-45 usada en venta

Este producto ya está en su lista de solicitud de cotización.

Amoladora de roscas universal de alta velocidad VIGERT S7520A usada a la venta

Este producto ya está en su lista de solicitud de cotización.

Rectificadora circular interna CNC SMTCL YK2110 usada en venta

Este producto ya está en su lista de solicitud de cotización.

Rectificadora de interiores versátil VIGERT MK2110 usada en venta

Este producto ya está en su lista de solicitud de cotización.

Rectificadora vertical versátil VIGERT de 2 metros 2MKM95200 usada en venta

Este producto ya está en su lista de solicitud de cotización.

Rectificadora vertical TAIYO KOKI usada IGV-3N con controlador FANUC 21i-TB

Este producto ya está en su lista de solicitud de cotización.

Valoraciones

No hay valoraciones aún.