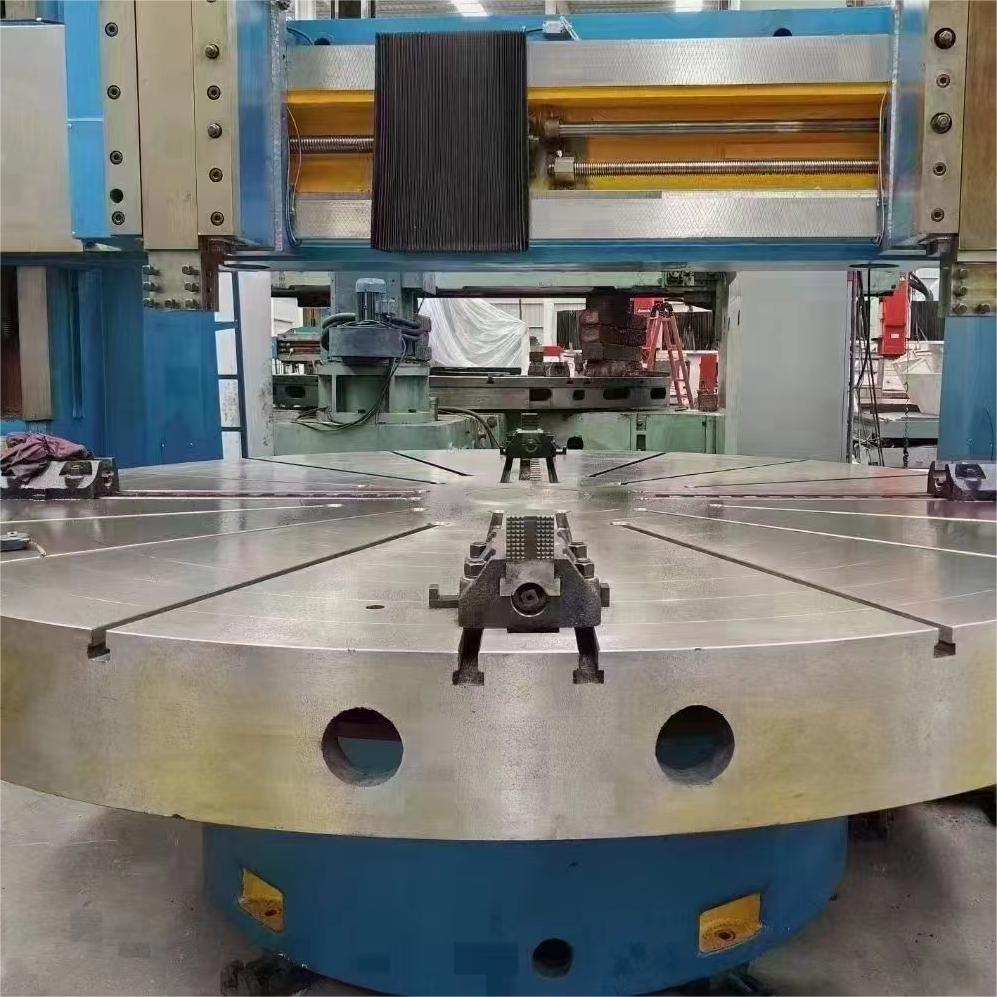

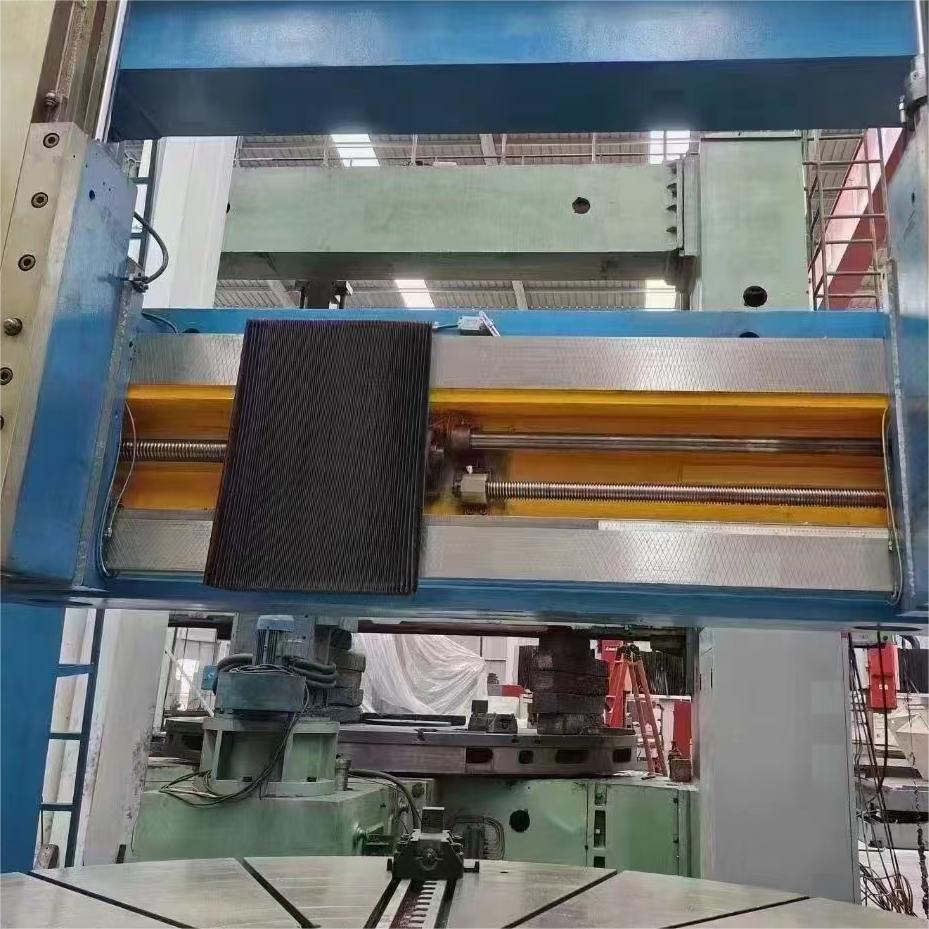

중고 VIGERT C5240E CNC 정밀 수직 선반 판매

| 무게 | 999 kg |

|---|---|

| 상태 |

90% 신규 |

| 기원 |

중국 |

| 지불 방법 |

LC ,티/티 |

| 가격 기간 |

EXW |

| 보증 |

1년 |

| 상표 |

비게르트 |

| 기능 |

갈기 |

| 제조 연도 |

2016 |

| 모델 |

C5240E |

15

지금 이 제품을 보고 있는 사람들!

설명

A CNC Precision Vertical Lathe is a specialized machine used for precision turning operations on large and heavy workpieces. It combines the capabilities of a conventional vertical lathe with computer numerical control (CNC) technology, enabling automated and highly accurate machining processes. Turning is a machining operation where a cutting tool removes material from the workpiece to create cylindrical or conical shapes.

Here’s a breakdown of the key features and components commonly found in a CNC Precision Vertical Lathe:

- Base and Column: The machine’s base and column provide stability and support for the components and workpieces. This ensures accurate machining by minimizing vibrations.

- Workholding Mechanism: CNC precision vertical lathe,The workpiece, which can be a large and heavy component, is securely held in a vertical orientation on a rotary table or chuck. The workholding mechanism allows for controlled rotation of the workpiece during machining.

- 도구 포탑: The tool turret or tool changer holds multiple cutting tools. It can be indexed to select different tools for various machining operations without manual intervention.

- 축: The spindle holds the cutting tool and provides the rotational motion necessary for turning. It can operate at various speeds and can be controlled for precise cutting conditions.

- Axis of Rotation (C-Axis): The workpiece can be rotated around its vertical axis, often referred to as the C-axis. This rotation allows the cutting tool to move along the workpiece’s length, creating cylindrical shapes and features.

- Axis of Vertical Movement (Z-Axis): The Z-axis controls the vertical movement of the cutting tool along the workpiece’s length. This axis determines the depth of cut and the final dimensions of the machined part.

- CNC 제어 시스템: The CNC control system, consisting of software and hardware components, guides the machine’s movements and machining processes. Operators input the desired specifications and parameters, and the control system translates these instructions into precise tool movements.

- 냉각수 시스템: A coolant system is used to cool and lubricate the cutting area, extend tool life, and evacuate chips from the machining zone.

- Enclosure: An enclosed design contains coolant, chips, and noise, enhancing operator safety and maintaining a clean working environment.

- Measuring and Inspection: Some CNC precision vertical lathes incorporate measuring and inspection systems to ensure the accuracy of machined features. These systems provide real-time feedback for adjustments during the machining process.

상품평 (0)

“Used VIGERT C5240E CNC Precision Vertical Lathe For Sale”의 첫 상품평을 남겨 주세요 명확하다

상품평

아직 상품평이 없습니다.