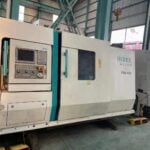

Used DOOSAN PUMA405 Machining Center For Sale

| Marca |

DOOSAN |

|---|---|

| Condiție |

90% Nou |

| Funcţie |

Centru de prelucrare |

| Anul MFG |

2013 |

| Model |

PUMA405 |

| garanție |

Un an |

| Termen de plata |

EXW |

| Modalitate de plată |

T/T |

| Origine |

COREEA |

10 în stoc

DOOSAN PUMA405 Machining Center

A DOOSAN PUMA405 Machining Center is a computer-controlled machine tool that can perform various machining operations with high precision and efficiency in a single setup. It combines the capabilities of a milling machine, drilling machine, and often other cutting processes such as tapping and boring into a single automated system. Machining centers are versatile and widely used in industries for the production of complex and precise components.

Here are the key features and components of a DOOSAN PUMA405 Machining Center:

Caracteristici cheie:

- Control CNC: Like other CNC machines, a machining center is controlled by a computer numerical control (CNC) system, which interprets the machining program and controls the movements and actions of the machine.

- Multi-Axis Movement: DOOSAN PUMA405 Machining Centers typically have three or more axes of movement, including X, Y, Z, and sometimes additional axes like A, B, or C for rotational or tilting movements. This allows for complex machining operations and multi-sided part processing.

- Schimbător automat de scule: DOOSAN PUMA405 Machining Centers are equipped with an automatic tool changer (ATC) that allows for quick and automated tool changes, enabling the use of multiple cutting tools without manual intervention.

- High Speed and Precision: DOOSAN PUMA405 Machining Centers are capable of high-speed machining and precise positioning, resulting in accurate and finely finished components.

- Versatilitate: They can perform a wide range of machining operations, including milling, drilling, tapping, boring, reaming, and more, making them highly versatile and suitable for diverse applications.

- Tool Holder Systems: Various tool holder systems are utilized, such as the CAT (V-flange), BT (tapered shank), HSK (hollow shank taper), and others, to secure cutting tools and enable efficient machining.

- Sistem de răcire: A coolant system is integrated to lubricate the cutting tools, cool the workpiece and tools, and evacuate chips generated during the machining process.

Components:

- Base and Frame: The base provides stability and support for the machining center, and the frame holds the main components such as the spindle and worktable.

- Ax: The spindle holds the cutting tool and rotates it at high speeds to perform cutting operations on the workpiece. It may have variable speeds and power.

- Masă de lucru: The worktable holds the workpiece and can move in various directions (X, Y, Z, A, B, C) to position the workpiece for machining.

- Tool Magazine: The tool magazine holds a variety of cutting tools and automatically selects and changes tools based on the machining program.

- Schimbător automat de scule (ATC): The ATC is a mechanism that automatically changes cutting tools during the machining process based on the programmed toolpath.

- Panou de control: The control panel or interface allows operators to input machining parameters, control the machine, monitor the machining process, and make adjustments.

- Transportor de așchii: A chip conveyor or evacuation system collects and removes chips generated during the machining process to maintain a clean work area.

Machining centers are essential in the manufacturing industry for producing complex parts with high precision, productivity, and repeatability. They are used in industries such as aerospace, automotive, medical device manufacturing, tool and die making, and more.

De ce să alegeți VIGERT?

VIGERT este un dealer profesionist de mașini pentru prelucrarea metalelor uzate în China de mulți ani, producțiile noastre au fost vândute în peste 100 de țări din lume!

Recenzii

Nu există recenzii până acum.