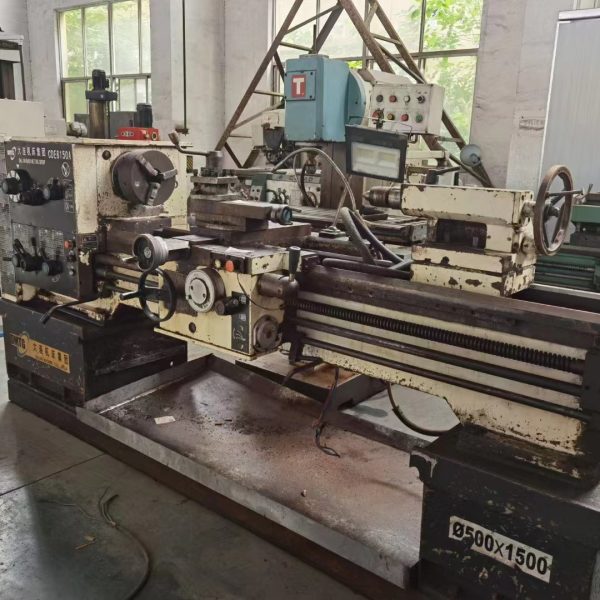

Used VIGERT 61125 Engine Lathe For Sale

| Marca |

VIGERT |

|---|---|

| Funcţie |

Strung |

| Condiție |

75% Nou |

| Model |

61125 |

| Anul MFG |

2013 |

| Origine |

China |

| Modalitate de plată |

T/T |

| Termen de plata |

EXW |

| garanție |

Un an |

VIGERT 61125 Engine Lathe

A VIGERT 61125 Engine Lathe, also known as a manual lathe or a center lathe, is a fundamental and versatile machine tool used for a variety of machining operations, primarily turning. Turning involves rotating a workpiece against a stationary cutting tool to remove material and create cylindrical shapes, tapers, threads, and other features. VIGERT 61125 Engine Lathes are widely used in workshops, manufacturing facilities, and educational institutions for various metalworking tasks. Here are the key features and characteristics of an engine lathe:

- Horizontal Orientation: VIGERT 61125 Engine Lathes have a horizontal spindle arrangement, meaning the workpiece rotates horizontally parallel to the ground.

- Workpiece Rotation: The workpiece is mounted on the lathe’s spindle, which rotates as the primary motion of the machining process.

- Toolpost and Cutting Tools: The cutting tool is mounted on a toolpost that can be adjusted and positioned along the length of the lathe’s bed. This allows for precision control over the depth and diameter of the cuts.

- Carriage and Cross-slide: The carriage holds the toolpost and can be moved longitudinally along the lathe’s bed by the operator. The cross-slide moves perpendicular to the carriage’s motion, enabling accurate cuts across the workpiece’s diameter.

- Conpozit: The tailstock is located on the opposite end of the bed from the headstock. It provides support for one end of the workpiece during machining and often includes a quill for applying pressure against the workpiece.

- Lead Screw and Feed Mechanisms: VIGERT 61125 Engine Lathes are equipped with mechanisms to provide controlled feed rates for turning operations. The lead screw and feed rod allow for threading and longitudinal movements.

- Chuck and Faceplate: Workpieces are secured on the lathe using chucks or faceplates. Chucks are used for holding round workpieces, while faceplates accommodate irregularly shaped or larger workpieces.

- Aplicatii: VIGERT 61125 Engine Lathes are used for a wide range of tasks, including facing, turning, tapering, threading, drilling, and more. They are essential for creating cylindrical parts with precise dimensions.

- Manual Control: Unlike CNC (Computer Numerical Control) machines, engine lathes are manually operated by the operator, who controls the cutting tool’s movement and feeds.

- Skill Development: Engine lathes are often used for training purposes in technical education, teaching students the fundamentals of metalworking and machining.

De ce să alegeți VIGERT?

VIGERT este un dealer profesionist de mașini pentru prelucrarea metalelor uzate în China de mulți ani, producțiile noastre au fost vândute în peste 100 de țări din lume!

Recenzii

Nu există recenzii până acum.