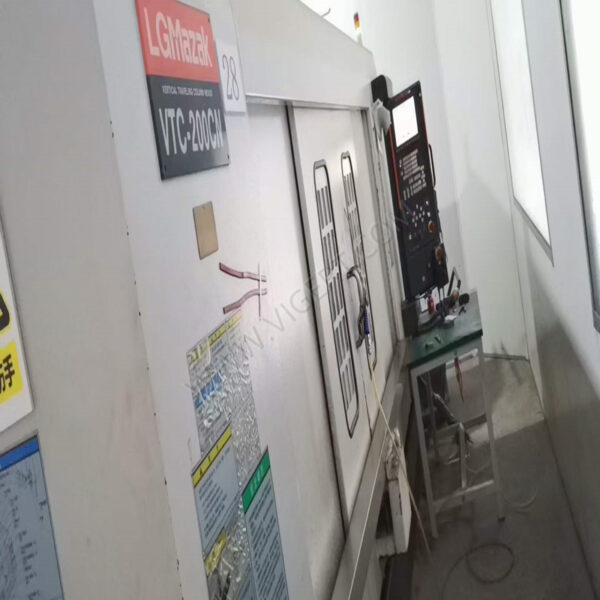

Used KDVM1370 practical Vertical Machining Center For Sale

| Марка |

КЕНТ |

|---|---|

| Состояние |

80% Новый |

| Функция |

Обрабатывающий центр |

| MFG Год |

2015 |

| Модель |

KDVM1370 |

| Источник |

Китай |

| Способ оплаты |

Т / Т |

| Срок действия цены |

EXW |

| Гарантия |

Один год |

practical Vertical Machining Center

A practical vertical machining center (VMC) is a versatile machine tool used in various manufacturing industries for precision machining operations. A VMC is designed to efficiently and accurately perform milling, drilling, and other operations on workpieces held in a vertical orientation. A “practical” VMC would typically refer to a machine that strikes a balance between functionality, features, and cost-effectiveness. Here are the key aspects of a practical vertical machining center:

- Pre

- cision and Accuracy: A practical VMC should offer reliable precision and accuracy, ensuring that finished parts meet the required tolerances and specifications.

- Жесткая конструкция: The machine’s construction should be sturdy and rigid to minimize vibrations and ensure stable machining, which is essential for achieving high-quality results.

- Tooling Flexibility: The VMC should accommodate a range of tool sizes and types, allowing operators to perform various machining operations, from roughing to finishing.

- Axis Configuration: Practical VMCs usually have 3-axis (X, Y, and Z) capabilities, which is suitable for many common machining tasks. Some models might have additional axes or

- capabilities like 4-axis or 5-axis machining.

- Work Envelope: The machine’s work envelope, which defines the maximum dimensions of the workpiece it can handle, should be appropriate for the types of parts you intend to produce.

- Система контроля: On the basis of practical Vertical Machining Center. The VMC should be equipped with a user-friendly CNC control system that enables efficient programming, operation, and monitoring of machining processes.

- Устройство смены инструмента: On the basis of practical Vertical Machining Center. A practical VMC would have an automatic tool changer (ATC) to facilitate quick tool changes, minimizing downtime between operations.

- Spindle Power and Speed: On the basis of practical Vertical Machining Center. The spindle’s power and speed range should be adequate for the materials and cutting tools you plan to use. A practical VMC would strike a balance between power and energy efficiency.

- Система охлаждения:

- An effective coolant system is important for maintaining tool life, improving surface finish, and managing chip removal.

- Operator Safety: Safety features such as enclosures, interlocks, and emergency stop buttons should be integrated to ensure the safety of operators.

- Совместимость с автоматизацией: While practical VMCs might not have advanced automation capabilities, they should still be compatible with basic automation solutions like pallet changers or robotic loaders.

- Область применения: A practical VMC should be versatile enough to handle a variety of materials, part sizes, and machining operations commonly found in industries like aerospace, automotive, and general manufacturing.

- Cost-Effective: A practical VMC aims to provide a good balance between features and cost, making it suitable for small to medium-sized businesses looking for reliable machining capabilities without unnecessary complexities.

- Обслуживание и поддержка: Practical VMCs should come with maintenance support, training options, and access to spare parts to ensure optimal machine performance and longevity.

Почему выбирают VIGERT?

VIGERT - профессиональный продавец подержанных металлообрабатывающих станков в Китае на протяжении многих лет, наша продукция продается более чем в 100 странах мира!

Отзывы

Отзывов пока нет.