Các phụ kiện máy ép thủy lực thiết yếu cho hiệu suất tối ưu và an toàn

To truly get the most out of your hydraulic press, they must be equipped with the right hydraulic press accessories. In this article, we’ll explore the top hydraulic press accessories that can significantly enhance performance, efficiency, and safety. Whether you’re a seasoned professional or just getting started, these must-have additions will take your hydraulic press operations to the next level.

Types of Thủy áp Accessories

Hydraulic presses are the workhorses of various industries, capable of exerting immense force with precision. While the hydraulic press itself is a powerful tool, its true potential is unlocked through a range of accessories designed to enhance performance, safety, and versatility. In this article, we will delve into the diverse world of hydraulic press accessories, exploring their types, functions, and applications.

Die Sets: Precision Shaping

Function: Die sets are essential accessories that determine the shape and form of materials during pressing operations. They provide precision and consistency, making them crucial for manufacturing and fabrication.

Types: Die sets come in various forms, including single-action dies for basic shapes and multiple-action dies for complex forms. Progressive dies are used for multi-step processes, offering efficiency in high-volume production.

Applications: Die sets find applications in industries such as metalworking, plastic molding, and even jewelry making, where precise shaping is paramount.

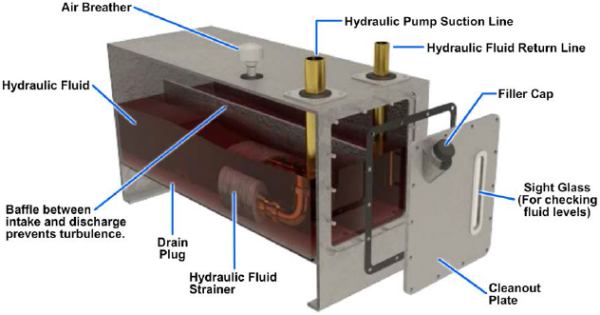

Hydraulic Fluids: The Lifeblood of the Press

Function: Hydraulic fluids serve as the vital medium for transmitting power, lubricating components, and dissipating heat within the hydraulic press. Choosing the right hydraulic fluid is crucial for efficient and trouble-free operation.

Types: Hydraulic fluids come in various types, including mineral oil-based, synthetic, and water-based fluids. The choice depends on factors such as viscosity requirements and temperature ranges.

Applications: Hydraulic fluids are essential in almost every hydraulic press application, from heavy-duty manufacturing to food processing.

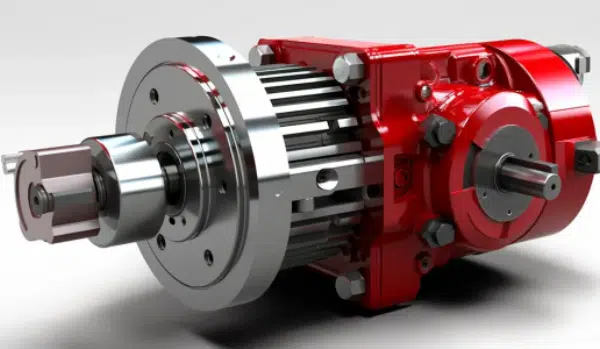

Hydraulic Pumps and Motors: Generating Power and Motion

Function: Hydraulic pumps and motors are responsible for generating the hydraulic force required for pressing tasks. These accessories determine the press’s power and speed.

Types: Hydraulic pumps can be gear pumps, vane pumps, or piston pumps, while hydraulic motors come in various designs such as radial piston motors or axial piston motors.

Applications: Hydraulic pumps and motors are at the heart of hydraulic presses, finding use in industries like construction, automotive, and aerospace.

Pressure Gauges and Sensors: Ensuring Safety and Precision

Function: Pressure gauges and sensors monitor the hydraulic pressure within the system, providing real-time feedback to ensure safe and accurate operations.

Types: Pressure gauges range from traditional analog dials to digital displays, while pressure sensors include pressure transducers and switches.

Applications: Pressure gauges and sensors are integral to applications where precision and safety are paramount, such as in the production of medical devices or aerospace components.

Safety Accessories

Safety is of paramount importance in any industrial setting, and when it comes to hydraulic presses—a powerful piece of machinery capable of exerting enormous force—the significance of safety is heightened. Safety accessories for hydraulic presses play a crucial role in mitigating risks, preventing accidents, and ensuring the well-being of operators. Let’s delve into the essential safety accessories designed to keep both personnel and equipment secure during hydraulic press operations.

Safety Guards:

Safety guards are physical barriers that enclose hazardous areas of the hydraulic press, preventing access to these areas during operation. They are designed to keep operators from inadvertently coming into contact with moving or dangerous components, minimizing the risk of injuries.

Interlocks:

Interlocks are safety devices that ensure certain conditions are met before allowing the hydraulic press to operate. These conditions could include proper closure of safety guards or the correct positioning of materials. Interlocks effectively reduce the likelihood of accidents by ensuring safe operating conditions.

Emergency Stop Systems:

Emergency stop systems, also known as e-stops or emergency stop buttons, are prominent safety features. When pressed, they instantly halt all hydraulic press operations, bringing the machine to a complete stop. This immediate response is critical in emergencies, preventing potential injuries or damage to the press.

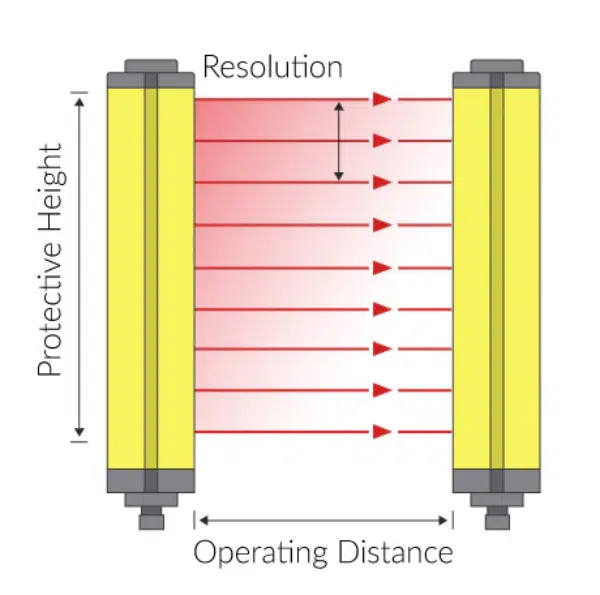

Light Curtains:

Light curtains are optical safety devices that create an invisible barrier or grid of light beams around the hydraulic press. If an operator or object breaks the light barrier, it triggers an automatic shutdown of the press, enhancing safety by preventing contact with hazardous areas.

Two-Hand Control Systems:

Two-hand control systems require the simultaneous activation of two separate controls by the operator to initiate a press operation. This ensures that both hands are away from the dangerous areas of the machine, enhancing safety and preventing inadvertent activation.

Safety Mats:

Safety mats are pressure-sensitive mats placed near the hydraulic press. If an operator steps onto the mat, it triggers a safety response such as stopping or halting the press operation. Safety mats are crucial in ensuring that operators are in safe positions before the press functions.

Sound and Visual Alarms:

These alarms provide audible and visible warnings to operators and other personnel when the press is about to start or if an unsafe condition is detected. They serve as a precautionary measure, alerting individuals to exercise caution.

Safety accessories for hydraulic presses are essential components that safeguard the well-being of operators and maintain a secure work environment. Integrating these safety measures not only reduces the risk of accidents but also enhances overall productivity and instills confidence in the workforce, allowing for smooth and efficient hydraulic press operations. It’s imperative for industries to prioritize safety and invest in the appropriate safety accessories to ensure responsible and secure use of hydraulic press machinery.

Maintenance and Lubrication Hydraulic Press Accessories

Maintenance and lubrication are critical aspects of keeping hydraulic presses in optimal condition. Hydraulic press accessories dedicated to maintenance and lubrication ensure that these powerful machines operate efficiently, and reliably, and have an extended lifespan. In this article, we will explore the significance of maintenance and lubrication accessories for hydraulic presses and how they contribute to the overall performance and longevity of the equipment.

Filters and Strainers

Hydraulic systems rely on clean fluids to function effectively. Filters and strainers are vital accessories that ensure hydraulic fluids remain free of contaminants and debris. They trap particles and impurities, preventing them from entering the hydraulic system and potentially damaging components. Regularly replacing and maintaining these filters and strainers is essential for the smooth and efficient operation of the hydraulic press.

Lubrication Systems

Proper lubrication is key to reducing friction and wear within the hydraulic press components. Lubrication accessories include centralized lubrication systems and automatic lubrication systems. These systems ensure that the moving parts of the press are adequately lubricated at all times, enhancing their performance and minimizing the risk of breakdowns.

Coolers and Heaters

Maintaining an optimal operating temperature is crucial for hydraulic press performance. Coolers and heaters are accessories that help regulate the temperature of the hydraulic fluid, preventing overheating or cold-start issues. These accessories play a vital role in extending the life of the hydraulic system and its components.

Gauges and Sensors for Monitoring

Monitoring the condition of a hydraulic press is essential for preventive maintenance. Pressure gauges and sensors are accessories that provide real-time data on the pressure, temperature, and other parameters of the hydraulic system. Monitoring these parameters allows operators to identify potential issues early and take necessary maintenance actions to prevent major problems.

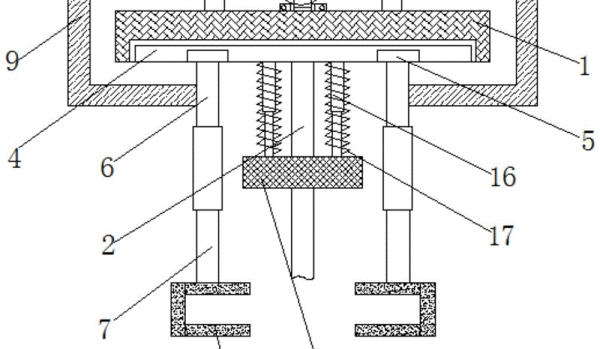

Seal Kits and O-rings

Hydraulic systems rely on seals and O-rings to prevent leaks and maintain pressure. Over time, these seals can wear out and need replacement. Seal kits and O-rings are maintenance accessories that provide the necessary components to replace worn or damaged seals, ensuring the hydraulic system remains leak-free and efficient.

Hydraulic Hose and Fittings

Hydraulic hoses and fittings are critical components that require regular inspection and replacement. These hydraulic press accessories ensure a secure and leak-free connection between various parts of the hydraulic system. Checking and replacing hoses and fittings as needed is essential for safe and efficient operation.

Maintenance and lubrication of hydraulic press accessories are indispensable for achieving optimal performance, longevity, and safety in hydraulic press operations. Investing in high-quality accessories and implementing regular maintenance schedules not only extends the life of the hydraulic press but also contributes to increased productivity, reduced downtime, and cost savings in the long run. Manufacturers and operators must prioritize the use of proper maintenance and lubrication accessories to ensure the hydraulic press operates at its best and delivers reliable results throughout its operational life.

Where to Find Hydraulic Press Accessories

Acquiring the right hydraulic press accessories is crucial to maintaining the efficiency, safety, and performance of hydraulic press machinery. Knowing where to find these accessories is essential for businesses and operators looking to enhance their hydraulic press operations. Here, we’ll explore various avenues where one can procure hydraulic press accessories to suit specific needs and applications.

Specialized Manufacturers and Suppliers:

Specialized manufacturers and suppliers of hydraulic press equipment often offer a wide range of compatible accessories. These entities focus on hydraulic systems and components, providing a diverse selection of die sets, hydraulic fluids, pressure gauges, safety features, and more. They understand the technical requirements and can offer expert guidance on the most suitable accessories for various applications.

Industrial Machinery Retailers:

Established industrial machinery retailers often have dedicated sections or departments catering to hydraulic press accessories. These retailers carry a variety of hydraulic press accessories such as hydraulic hoses, fittings, lubrication systems, and safety components. Their product offerings cater to a broad spectrum of industries, ensuring accessibility to a wide range of accessories.

Online Marketplaces:

E-commerce platforms have emerged as convenient and comprehensive sources for hydraulic press accessories. Online marketplaces offer a vast array of options, enabling buyers to compare prices, features, and specifications before making a purchase. This avenue provides easy access to both standard and specialized accessories from a multitude of sellers.

Local Distributors and Dealers:

Local distributors and dealers that specialize in industrial equipment often stock hydraulic press accessories. These establishments may have knowledgeable staff who can provide insights and recommendations based on specific requirements. Additionally, sourcing accessories locally can expedite procurement and reduce shipping lead times.

Industry Trade Shows and Exhibitions:

Industry trade shows, exhibitions, and conferences related to manufacturing, engineering, or industrial equipment often feature displays from manufacturers and suppliers of hydraulic press accessories. These events provide an excellent opportunity to physically examine the accessories, interact with experts, and establish direct connections with potential suppliers.

Networking and Industry Associations:

Networking within the industry and engaging with industry associations can lead to valuable recommendations and referrals for reputable suppliers of hydraulic press accessories. Industry professionals often share their experiences and insights, guiding others to reliable sources for the required accessories.

Equipment Service Providers:

Service providers who specialize in hydraulic press maintenance and repairs often have access to a range of hydraulic press accessories. Engaging with these providers can be advantageous, as they not only offer accessories but can also provide insights into the best-fit accessories for specific hydraulic press models.

In conclusion, the accessibility of hydraulic press accessories is diverse and expansive, providing ample options to suit varying needs and preferences. Whether through specialized manufacturers, online platforms, local suppliers, or industry events, businesses, and operators can find the right hydraulic press accessories to optimize performance, enhance safety, and prolong the life of their hydraulic press machinery. It’s essential to research and choose reputable sources to ensure the quality and compatibility of the accessories with the thủy áp system.