10 tính năng hàng đầu cần có ở một máy đục lỗ hiện đại

Punching machines have evolved significantly over the years, transitioning from simple mechanical devices to advanced, computer-controlled systems. These machines are crucial in various industries, including metalworking, automotive, and electronics, where precision and efficiency are paramount. Choosing the right punching machine can greatly enhance production quality and speed while reducing operational costs. This article delves into the top ten features you should look for when investing in a modern punching machine.

1. Độ chính xác và độ chính xác cao of Máy đột

One of the most critical features of a modern punching machine is its ability to perform high-precision and accurate punches. Precision is crucial for ensuring that each hole or cut is placed exactly where it should be, which is vital in applications where even the slightest deviation can lead to significant issues.

Modern punching machines are equipped with advanced control systems, such as CNC (Computer Numerical Control), that allow for incredibly precise movements. CNC systems can control the position, speed, and path of the punch with remarkable accuracy, often within microns. This precision ensures consistency and quality across large production runs.

2. Versatility in Material Handling

A modern punching machine should be capable of handling a wide range of materials and thicknesses. This versatility is essential for manufacturers who work with various metals and need to switch between different types of materials without having to invest in multiple machines.

Look for a machine that can handle materials such as aluminium, stainless steel, copper, and even some non-metallic materials like plastics or composites. Additionally, the machine should be able to handle different thicknesses, from thin sheets to thick plates, to accommodate diverse production needs.

3. Advanced Tooling Options

The tooling options available for a punching machine can significantly impact its performance and versatility. Modern punching machines should support a wide variety of tooling configurations, including standard and custom tools. This flexibility allows manufacturers to perform a range of operations, such as punching, forming, tapping, and engraving, with a single machine.

Advanced tooling systems often include quick-change mechanisms that minimize downtime during tool changes. Some machines also feature automatic tool changers, which can hold multiple tools and switch between them as needed without manual intervention, further enhancing productivity.

4. High-Speed Operation

Speed is a crucial factor in any manufacturing process, and modern punching machines are designed to deliver high-speed operations without sacrificing precision or quality. High-speed punching machines can perform thousands of strokes per minute, significantly increasing throughput and reducing production time.

When evaluating a machine’s speed, consider both the punching speed (the number of hits per minute) and the feed rate (the speed at which the material is moved into position). Machines with high punching speeds and fast feed rates can handle large production volumes efficiently, making them ideal for high-demand environments.

5. Hiệu quả năng lượng

As energy costs continue to rise, energy efficiency has become a key consideration for manufacturers. Modern punching machines are designed with energy-saving features that help reduce power consumption without compromising performance.

Look for machines that incorporate features like regenerative braking, which recovers and reuses energy generated during machine operation. Additionally, some machines use servo-electric drives instead of traditional hydraulic systems, which can be more energy-efficient and environmentally friendly.

6. User-friendly interface and Software

A modern punching machine should come with a user-friendly interface and powerful software that makes programming and operation straightforward and intuitive. CNC machines, in particular, rely on sophisticated software for programming and control, so it’s essential that the interface is easy to use, even for operators with limited experience.

Features to look for include touch-screen controls, graphical programming interfaces, and the ability to import CAD files directly. Software that supports offline programming can also be beneficial, allowing operators to create and test programs without taking the machine offline, which enhances productivity.

7. Robust Construction and Durability

Durability is a key factor in the longevity and reliability of a punching machine. Modern machines should be constructed from high-quality materials that can withstand the rigours of continuous operation and heavy use.

Look for machines with a robust frame and components that are designed to minimize vibration and maintain stability during operation. This not only extends the machine’s lifespan but also contributes to higher accuracy and precision by reducing the potential for movement or misalignment during punching.

8. Automation and Integration Capabilities

Automation is increasingly important in modern manufacturing, and punching machines are no exception. Advanced machines come equipped with features like automatic loading and unloading, part sorting, and integration with other systems, such as robotic arms or conveyor belts.

These automation capabilities can greatly enhance efficiency and reduce the need for manual intervention, leading to lower labour costs and faster production times. Additionally, the ability to integrate with other manufacturing systems and software enables seamless workflow management and data sharing across different stages of the production process.

9. Các tính năng an toàn

Safety is paramount in any manufacturing environment, and modern punching machines should come with a range of safety features to protect operators and equipment. These may include physical barriers, emergency stop buttons, light curtains, and safety interlocks that prevent the machine from operating when guards are not in place.

Some machines also feature advanced monitoring systems that can detect issues like tool wear or material misfeeds and automatically stop the machine to prevent damage or accidents. Ensuring that the machine complies with relevant safety standards and regulations is also essential for maintaining a safe working environment.

10. Comprehensive After-Sales Support

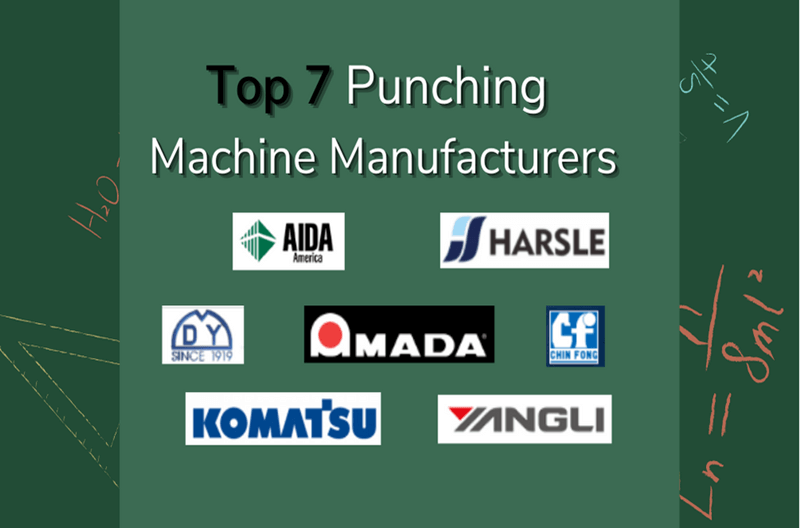

Investing in a punching machine is a significant commitment, and having access to comprehensive after-sales support can make a substantial difference in the machine’s long-term performance and reliability. Look for manufacturers or suppliers that offer extensive support services, including training, maintenance, repairs, and access to spare parts.

Good after-sales support ensures that any issues can be quickly addressed, minimizing downtime and keeping your production line running smoothly. It also provides peace of mind, knowing that you have expert assistance available whenever you need it.

Phần kết luận

Choosing the right punching machine involves considering a range of features that can impact your production efficiency, quality, and overall operational costs. High precision and accuracy, versatility in material handling, advanced tooling options, high-speed operation, and energy efficiency are just a few of the critical features to look for.

Additionally, a user-friendly interface, robust construction, automation capabilities, comprehensive safety features, and strong after-sales support are all essential factors that contribute to the overall value and performance of the machine. By carefully evaluating these features, you can select a modern punching machine that meets your specific needs and helps you achieve your manufacturing goals.

Investing in a high-quality, feature-rich punching machine not only enhances your production capabilities but also positions your business for future growth and success in an increasingly competitive market.