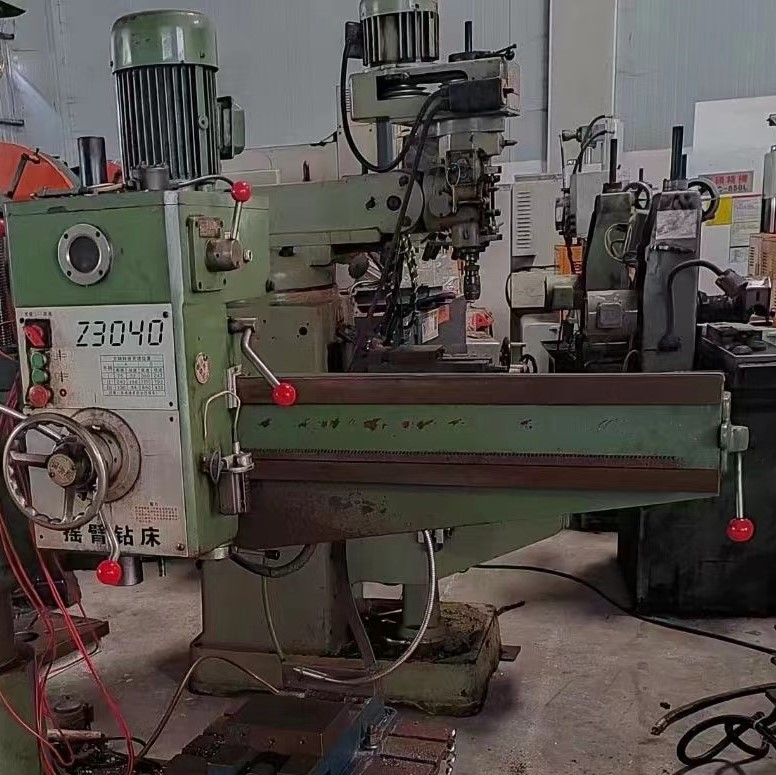

Máy khoan xuyên tâm VIGERT Z3040 đã qua sử dụng để bán

| Nhãn hiệu |

VIGERT |

|---|---|

| Tình trạng |

85% Mới |

| Hàm số |

khoan |

| Năm MFG |

2015 |

| Người mẫu |

Z3040 |

| Phương thức thanh toán |

T / T |

| Gốc |

Trung Quốc |

| Thời hạn giá |

EXW |

| Sự bảo đảm |

Một năm |

Máy khoan xuyên tâm Z3040

A Z3040 Radial Drilling Machine is a type of machine tool used for drilling holes in various materials, typically metal. It’s characterized by its radial arm, which can be moved in an arc around a central vertical column. This design allows the drill to reach different positions on the workpiece without needing to move the workpiece itself. Radial drilling machines are known for their versatility, as they can handle a wide range of drilling tasks, including drilling, tapping, counterboring, and reaming.

Key features and components of a radial drilling machine include:

Base: The base provides stability and support for the entire machine. It’s designed to withstand the vibrations and forces generated during drilling operations.

Column: On the basis of Z3040 Radial Drilling Machine. The vertical column supports the radial arm and provides vertical movement for the arm.

Radial Arm: On the basis of Z3040 Radial Drilling Machine. The radial arm is the distinguishing feature of the radial drilling machine. It can rotate around the vertical column, allowing the drill head to be positioned at various distances from the column and workpiece.

Drill Head: On the basis of Z3040 Radial Drilling Machine. The drill head houses the motor, spindle, and other components necessary for drilling operations. It can be raised or lowered along the radial arm to adjust the drilling depth.

Con quay: On the basis of Z3040 Radial Drilling Machine. The spindle holds the cutting tool, such as a drill bit, and provides the rotation needed for drilling. It can be equipped with different types of tool holders to accommodate various tool sizes and types.

Bàn: The table provides a flat surface for supporting the workpiece during drilling. It can be adjusted in height and rotated around the column to position the workpiece accurately.

Cơ chế kẹp: The workpiece is typically secured to the table using clamps or vises to prevent movement during drilling.

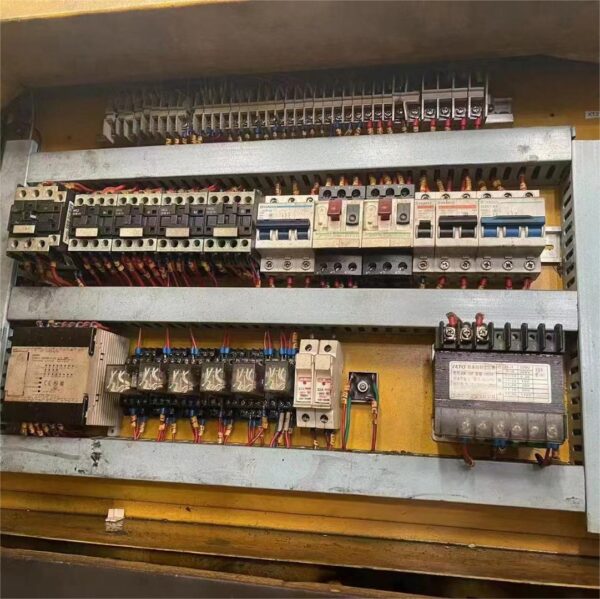

Control Mechanism: Many modern radial drilling machines are equipped with controls that allow for adjusting spindle speed, feed rate, and other parameters. Some machines may have digital readouts for accurate positioning.

Hệ thống làm mát: A coolant system is often integrated to lubricate the cutting tool and workpiece, prevent overheating, and remove chips.

Tại sao chọn VIGERT?

VIGERT là đại lý máy gia công kim loại đã qua sử dụng chuyên nghiệp tại Trung Quốc trong nhiều năm, các sản phẩm của chúng tôi đã được bán cho hơn 100 quốc gia trên thế giới!

Đánh giá

Chưa có đánh giá nào.