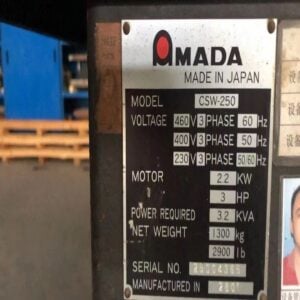

Prodám NOVOU hydraulickou drážkovačku AMADA CSW-250

| Značka |

AMADA |

|---|---|

| Stav |

99% Nový |

| Funkce |

Zářez |

| Rok MFG |

2023 |

| Modelka |

CSW-250 |

| Původ |

Japonsko |

| Způsob platby |

LC ,T/T |

| Cenový termín |

EXW |

| Záruka |

Jeden rok |

10 skladem

A AMADA CSW-250 Hydraulic Notcher typically consists of a sturdy frame housing various components required for the notching process. The key components of a AMADA CSW-250 Hydraulic Notcher include:

- Řezací mechanismus: This can vary depending on the type of notching machine. It may feature a rotating saw blade, a punching tool, or an abrasive wheel. The cutting mechanism is responsible for removing material to create the notch.

- Systém upínání obrobků: To secure the workpiece in place during the notching process, a variety of clamping mechanisms or fixtures are often employed. These ensure that the workpiece remains stable and accurately positioned throughout the operation.

- Adjustment Mechanisms: Notching machines typically feature adjustment mechanisms that allow for precise control over the depth, width, and angle of the notch being created. These adjustments can be manual, hydraulic, or controlled electronically, depending on the complexity of the machine.

- Bezpečnostní funkce: Given the potential hazards associated with operating machinery, notching machines are equipped with various safety features to protect operators. These may include guards around moving parts, emergency stop buttons, and safety interlocks.

- Power Source: AMADA CSW-250 Hydraulic Notcher s may be powered by electricity, hydraulics, or pneumatics, depending on their size and intended application. Larger industrial machines often use hydraulic power for increased cutting force and precision.

- Řídicí rozhraní: In modern notching machines, especially those equipped with automation or CNC capabilities, there is typically a control interface where operators can input parameters such as notch dimensions, cutting speed, and other settings.

Aplikace: AMADA CSW-250 Hydraulic Notcher s find applications in a wide range of industries, including metal fabrication, automotive manufacturing, aerospace, construction, and woodworking. They are used to create various components such as brackets, frames, chassis, sheet metal panels, tubing, and profiles with precise cutouts or notches.

Závěr: In summary, a AMADA CSW-250 Hydraulic Notcher is a versatile and essential tool in many manufacturing processes, offering the capability to produce intricate shapes and profiles with high accuracy and repeatability. Its versatility, combined with its ability to handle a wide range of materials, makes it indispensable in modern manufacturing operations.

Proč si vybrat VIGERT?

VIGERT je profesionální prodejce použitých kovoobráběcích strojů v Číně po mnoho let, naše produkce byla prodána do více než 100 zemí světa!

Recenze

Zatím zde nejsou žádné recenze.