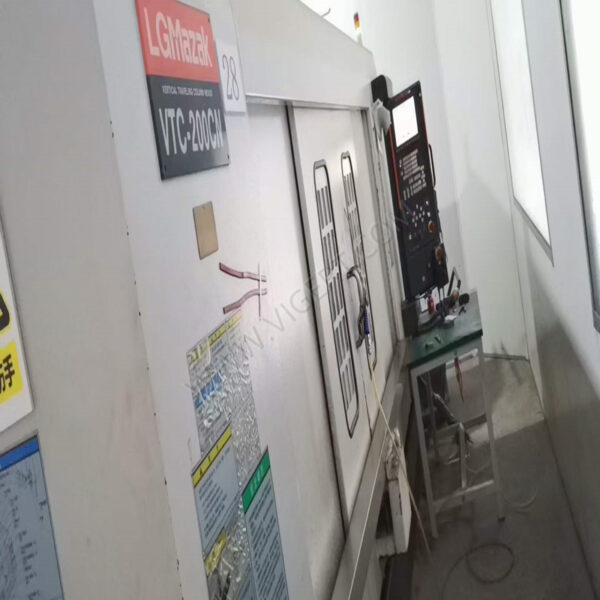

Used KDVM1370 practical Vertical Machining Center For Sale

| Značka |

KENT |

|---|---|

| Stav |

80% Nový |

| Funkce |

Obráběcí centrum |

| Rok MFG |

2015 |

| Modelka |

KDVM1370 |

| Původ |

Čína |

| Způsob platby |

T/T |

| Cenový termín |

EXW |

| Záruka |

Jeden rok |

24

Lidé nyní sledují tento produkt!

Popis

practical Vertical Machining Center

A practical vertical machining center (VMC) is a versatile machine tool used in various manufacturing industries for precision machining operations. A VMC is designed to efficiently and accurately perform milling, drilling, and other operations on workpieces held in a vertical orientation. A “practical” VMC would typically refer to a machine that strikes a balance between functionality, features, and cost-effectiveness. Here are the key aspects of a practical vertical machining center:

- Pre

- cision and Accuracy: A practical VMC should offer reliable precision and accuracy, ensuring that finished parts meet the required tolerances and specifications.

- Tuhá konstrukce: The machine’s construction should be sturdy and rigid to minimize vibrations and ensure stable machining, which is essential for achieving high-quality results.

- Flexibilita nástrojů: The VMC should accommodate a range of tool sizes and types, allowing operators to perform various machining operations, from roughing to finishing.

- Axis Configuration: Practical VMCs usually have 3-axis (X, Y, and Z) capabilities, which is suitable for many common machining tasks. Some models might have additional axes or

- capabilities like 4-axis or 5-axis machining.

- Work Envelope: The machine’s work envelope, which defines the maximum dimensions of the workpiece it can handle, should be appropriate for the types of parts you intend to produce.

- Kontrolní systém: On the basis of practical Vertical Machining Center. The VMC should be equipped with a user-friendly CNC control system that enables efficient programming, operation, and monitoring of machining processes.

- Měnič nástrojů: On the basis of practical Vertical Machining Center. A practical VMC would have an automatic tool changer (ATC) to facilitate quick tool changes, minimizing downtime between operations.

- Spindle Power and Speed: On the basis of practical Vertical Machining Center. The spindle’s power and speed range should be adequate for the materials and cutting tools you plan to use. A practical VMC would strike a balance between power and energy efficiency.

- Chladicí systém:

- An effective coolant system is important for maintaining tool life, improving surface finish, and managing chip removal.

- Operator Safety: Safety features such as enclosures, interlocks, and emergency stop buttons should be integrated to ensure the safety of operators.

- Automation Compatibility: While practical VMCs might not have advanced automation capabilities, they should still be compatible with basic automation solutions like pallet changers or robotic loaders.

- Application Range: A practical VMC should be versatile enough to handle a variety of materials, part sizes, and machining operations commonly found in industries like aerospace, automotive, and general manufacturing.

- Cost-Effective: A practical VMC aims to provide a good balance between features and cost, making it suitable for small to medium-sized businesses looking for reliable machining capabilities without unnecessary complexities.

- Maintenance and Support: Practical VMCs should come with maintenance support, training options, and access to spare parts to ensure optimal machine performance and longevity.

Hodnocení (0)

Buďte první, kdo ohodnotí „Used KDVM1370 practical Vertical Machining Center For Sale“ Zrušit odpověď na komentář

O společnosti VIGERT

Proč si vybrat VIGERT?

VIGERT je profesionální prodejce použitých kovoobráběcích strojů v Číně po mnoho let, naše produkce byla prodána do více než 100 zemí světa!

Související produkty

Použité vertikální obráběcí centrum CNC DOOSAN DNM6705 na prodej

Hodnocení 5.00 z 5

Recenze

Zatím zde nejsou žádné recenze.