Used MAKINO F5 Machining Center For Sale

| Marke |

MAKINO |

|---|---|

| Zustand |

95% Neu |

| Funktion |

Schneiden |

| MFG-Jahr |

2016 |

| Modell |

F5 |

| Preisbedingung |

EXW |

| Herkunft |

Japan |

| Bezahlverfahren |

T/T |

| Garantie |

Ein Jahr |

10 vorrätig

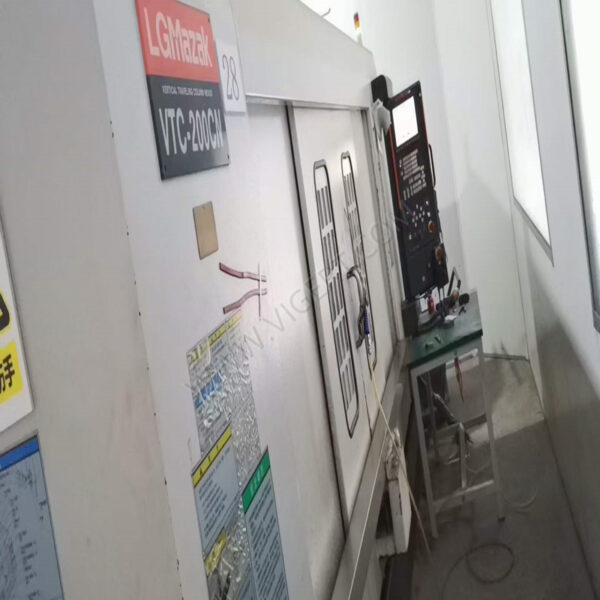

A Used MAKINOF5 Machining Center , also known as a CNC (Computer Numerical Control) machining center, is a highly automated manufacturing machine used for various machining operations, such as milling, drilling, tapping, and other processes. It is a computer-controlled machine tool that can perform complex and precise cuts on various materials, including metal, plastic, and composites.

Here are key features and components of a typical Used MAKINO F5 Steady Machining Center :

- Machine Structure:

- F5 Machining Center. The machine’s structure comprises a bed or base, columns, a spindle, and a worktable. The bed provides stability and support for the machine components.

- Spindel:

- F5 Machining Center. The spindle is a critical component that holds and rotates the cutting tool. It’s responsible for the actual machining processes, such as cutting, drilling, and milling.

- Werkzeugwechsler:

- Machining centers often have an automatic tool changer (ATC) that allows for quick and automated changes of cutting tools during the machining process. This enhances efficiency and minimizes downtime.

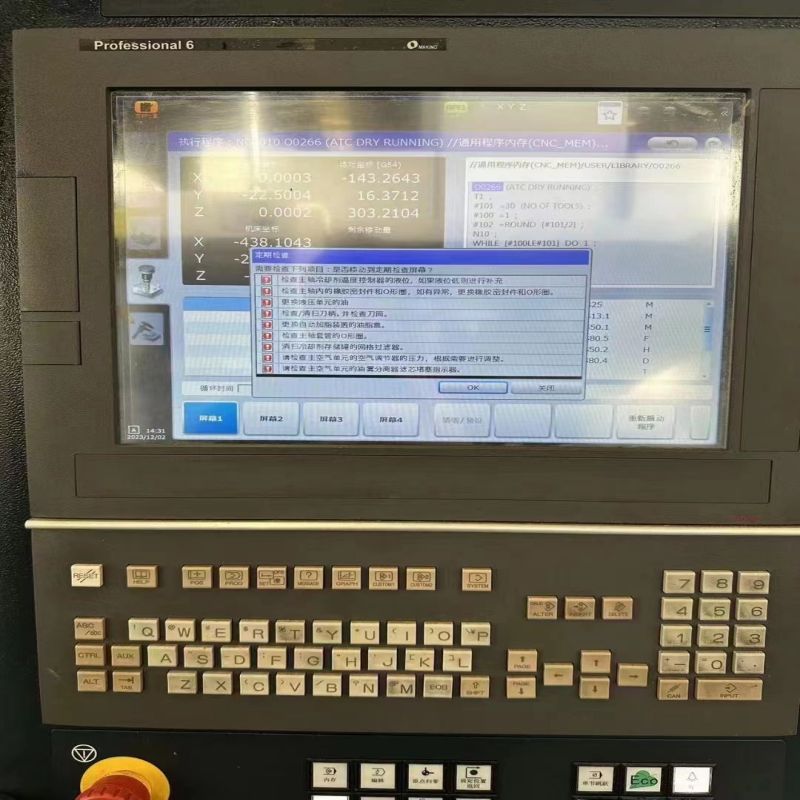

- Steuerungssystem:

- The control system includes a computer, software, and a control panel that enables the operator to program and control the machining operations. CNC programming dictates the tool’s path, speed, and depth of cut.

- Arbeitstisch:

- The worktable holds the workpiece in place during machining. It can move in different directions (X, Y, and Z axes) to position the workpiece for machining at various angles and orientations.

- Axes:

- F5 Machining center typically have three or more axes (X, Y, Z) that allow for movement and positioning of the cutting tool in three-dimensional space.

- Kühlmittelsystem:

- F5 Machining generates heat, so a coolant system is often incorporated to keep the cutting tools and workpiece at appropriate temperatures, prolonging tool life and improving machining accuracy.

- Guideways and Linear Motion Systems:

- These systems enable smooth and precise movement of the machine components, ensuring accurate machining.

- Sicherheitsvorrichtungen:

- Used MAKINO Machining Center s are equipped with safety features like emergency stop buttons, interlocks, and safety guards to ensure operator safety during machine operation.

Used MAKINO Machining Center s are widely used in various industries, including automotive, aerospace, medical, and manufacturing, due to their ability to produce complex and high-precision parts efficiently. CNC programming allows for a high level of automation, accuracy, and repeatability in manufacturing processes.

Warum VIGERT wählen?

VIGERT ist seit vielen Jahren ein professioneller Händler für gebrauchte Metallbearbeitungsmaschinen in China, unsere Produktionen wurden in über 100 Länder der Welt verkauft!

Rezensionen

Es gibt noch keine Rezensionen.