Safety Measures and Best Practices for Operating Rolling Machines

Operating rolling machines is a critical aspect of the metalworking and manufacturing industries. These machines, used to bend and shape metal sheets into cylindrical forms, play a pivotal role in producing various components essential for multiple applications. However, the operation of rolling machines poses significant safety risks, making it imperative to adhere to stringent safety measures and best practices. This article explores comprehensive safety measures and best practices for operating rolling machines, ensuring a safe and efficient work environment.

Understanding Rolling Machines

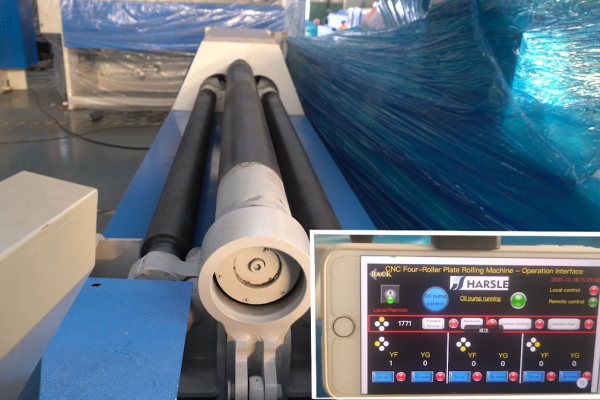

Rolling machines, also known as plate rolls or bending rolls, come in various types, including three-roller and four-roller machines. These machines are designed to bend and shape metal sheets into cylindrical or conical shapes by passing the metal through a series of rollers that apply pressure to achieve the desired curvature. The precise control and handling of these machines require skilled operators and a robust understanding of safety protocols.

Importance of Safety Measures

The operation of rolling machines involves several hazards, including:

- Pinch Points: Where the metal sheet enters the rollers, posing a risk of fingers or hands getting caught.

- High Pressure: The force exerted by the rollers can cause severe injuries if proper precautions are not taken.

- Heavy Materials: Handling and maneuvering large, heavy metal sheets can lead to strains and injuries.

- Machine Malfunctions: Faulty or poorly maintained machines can lead to accidents.

Implementing comprehensive safety measures can significantly mitigate these risks, ensuring the well-being of operators and the efficient functioning of the machines.

Pre-Operation Safety Checks

Before commencing any operation with a rolling machine, it is essential to conduct thorough safety checks to ensure the machine is in proper working condition and that the operators are prepared.

1. Inspect the Machine

Visual Inspection: Check for any visible damage or wear on the rollers, gears, and other components.

Safety Guards: Ensure all safety guards and emergency stop buttons are in place and functional.

Bedienfeld: Verify that the control panel is working correctly and that all indicators and displays are operational.

2. Review Safety Procedures

Operating Manual: Ensure all operators are familiar with the machine’s operating manual and safety procedures.

Safety Briefing: Conduct a safety briefing to review the operation plan and potential hazards.

3. Personal Protective Equipment (PPE)

Appropriate Gear: Operators should wear appropriate PPE, including gloves, safety glasses, and steel-toed boots.

Securing Attire: Loose clothing, jewelry, and long hair should be secured to prevent them from getting caught in the machine.

Safe Operation Practices

Following best practices during the operation of rolling machines is crucial to maintaining safety and efficiency.

1. Proper Training

Certified Training: Ensure all operators are adequately trained and certified to use the rolling machine.

Refresher Courses: Provide regular refresher training sessions to keep operators updated on safety protocols and machine operation.

2. Clear Communication

Team Coordination: Maintain clear communication among team members involved in the operation.

Noise Management: Use hand signals or radios if the noise level in the workspace is high to ensure effective communication.

3. Machine Setup

Manufacturer Guidelines: Set up the machine according to the manufacturer’s guidelines and the specific requirements of the job.

Roller Adjustment: Adjust the rollers to the appropriate settings for the material thickness and desired bend radius.

4. Feeding the Material

Mechanical Aids: Use mechanical aids or team assistance to handle and feed heavy metal sheets into the machine.

Alignment: Ensure that the sheet is aligned correctly to prevent jamming or uneven bends.

5. Monitoring the Operation

Continuous Monitoring: Continuously monitor the machine and the material during the operation.

Safe Distance: Keep hands and other body parts away from pinch points and moving parts.

6. Emergency Procedures

Emergency Stops: Know the location of the emergency stop buttons and how to use them.

Response Protocol: Establish a clear protocol for responding to emergencies and accidents, ensuring all team members are aware of their roles.

Post-Operation Safety

After completing the operation, it is essential to follow proper shutdown and maintenance procedures to ensure continued safety and efficiency.

1. Machine Shutdown

Power Down: Turn off the machine and ensure it has come to a complete stop before performing any maintenance or adjustments.

Disconnect Power: Disconnect the power supply to prevent accidental startups.

2. Material Handling

Safe Removal: Safely remove the finished product from the machine using mechanical aids or team assistance.

Proper Storage: Store the finished product in a designated area to prevent clutter and potential hazards.

3. Cleaning and Maintenance

Debris Removal: Clean the machine and the surrounding area to remove any metal shavings or debris.

Inspection: Inspect the machine for any signs of wear or damage and perform necessary maintenance.

Regular Maintenance

Regular maintenance is crucial for the safe and efficient operation of rolling machines, helping prevent malfunctions and extending the machine’s lifespan.

1. Scheduled Inspections

Component Check: Conduct regular inspections of the machine components, including rollers, gears, and hydraulic systems.

Wear and Tear: Check for any signs of wear, corrosion, or damage and replace faulty parts promptly.

2. Lubrication

Proper Lubricants: Ensure all moving parts are adequately lubricated to reduce friction and wear.

Manufacturer Recommendations: Use the recommended lubricants as specified by the manufacturer.

3. Calibration

Periodic Calibration: Periodically calibrate the machine to ensure it produces accurate and consistent results.

Follow Guidelines: Adhere to the manufacturer’s guidelines for calibration procedures.

4. Record Keeping

Maintenance Logs: Maintain detailed records of all maintenance activities, including inspections, repairs, and part replacements.

Performance Tracking: Use these records to track the machine’s performance and plan future maintenance schedules.

Enhancing Safety Culture

Promoting a strong safety culture within the workplace is essential for the long-term safety of operators and other employees.

1. Safety Training

Regular Sessions: Provide regular safety training sessions for all employees, focusing on the specific hazards associated with rolling machines.

Emergency Response: Include training on emergency response procedures and first aid.

2. Safety Audits

Identify Hazards: Conduct regular safety audits to identify potential hazards and areas for improvement.

Employee Involvement: Involve employees in the audit process to gain their insights and promote a culture of safety.

3. Employee Involvement

Report Concerns: Encourage employees to report any safety concerns or near-miss incidents.

Address Issues: Create a system for addressing and resolving safety issues promptly.

4. Safety Incentives

Reward Compliance: Implement a safety incentive program to reward employees for following safety protocols and maintaining a safe work environment.

Celebrate Milestones: Recognize and celebrate milestones, such as periods without accidents or injuries.

Abschluss

Operating rolling machines safely requires a combination of proper training, diligent maintenance, and a strong safety culture. By following these safety measures and best practices, operators can minimize the risk of accidents and ensure a safe and productive work environment. Regular training, clear communication, and adherence to safety protocols are essential for the safe operation of rolling machines. Implementing these practices not only protects employees but also enhances the efficiency and longevity of the machines, contributing to the overall success of the manufacturing process.

In conclusion, a proactive approach to safety, involving comprehensive training, regular maintenance, and fostering a safety-first culture, is paramount in the operation of rolling machines. By prioritizing these aspects, businesses can safeguard their workforce, maintain high productivity levels, and ensure the seamless operation of their rolling machines.