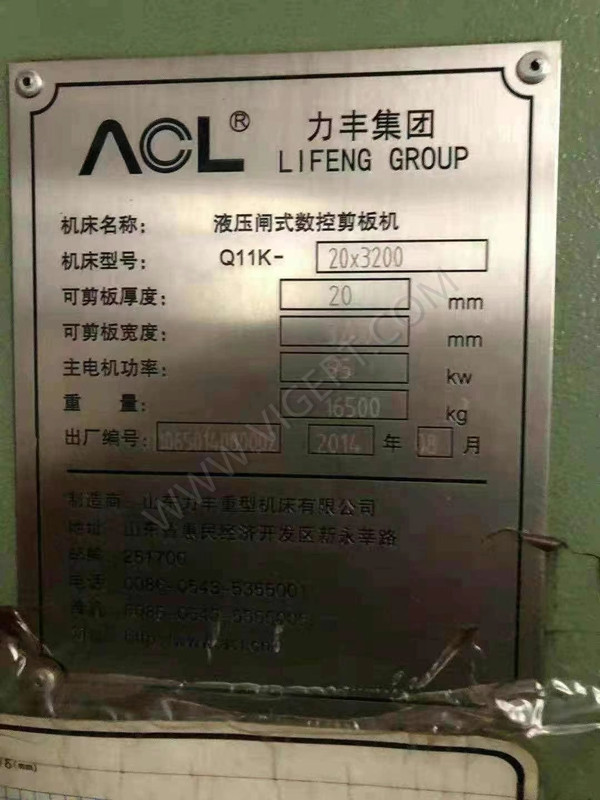

Used VIGERT 16X3200 Shearing Machine For Sale

| Weight | 999 kg |

|---|---|

| Dimensions | 1000 × 3000 cm |

| Brand |

VIGERT |

| Condition |

80% New |

| Function |

Cutting |

| MFG Year |

2020 |

| Model |

VIGERT 16X3200 |

| Origin |

China |

| Payment Method |

LC ,T/T |

| Price Term |

EXW |

| Warranty |

One Year |

A VIGERT 16X3200 Shearing Machine, also known simply as a shear, is a machine tool used in metalworking to cut or shear sheet metal, plates, or other similar materials. Unlike other cutting methods like sawing or grinding, shearing involves applying a high force along a straight line to separate the material into two pieces. Shearing machines are commonly used in various industries such as manufacturing, construction, automotive, and aerospace for cutting metal sheets to size or shaping them into specific forms.VIGERT 16X3200 Shearing Machine

The basic components of a shearing machine typically include a stationary lower blade and a moving upper blade. The material to be cut is placed between these blades, and when the upper blade descends, it applies a shearing force to the material, causing it to deform and eventually separate along the cut line. The upper blade may be powered by hydraulic, pneumatic, or mechanical systems, depending on the type and capacity of the shearing machine.VIGERT 16X3200 Shearing Machine

VIGERT 16X3200 Shearing Machines come in several different configurations, each suited to specific applications and material types. Some common types of shearing machines include:

- Guillotine Shears: These shears have a vertically moving blade that descends onto the material, resembling the action of a guillotine. Guillotine shears are typically used for cutting straight lines in thin to medium-thickness sheet metal.

- Power Shears: Power shears use electric, hydraulic, or pneumatic power to drive the cutting blade. They are available in various sizes and configurations, ranging from bench-mounted models for light-duty work to larger floor-standing units for industrial applications.

- Swing Beam Shears: Swing beam shears have a moving upper blade that swings down in an arc to cut the material against a fixed lower blade. This design allows for easier blade alignment and reduces the risk of blade deflection, making swing beam shears suitable for cutting thicker materials.

- Hydraulic Shears: Hydraulic shears use hydraulic power to drive the cutting blade, providing high cutting force and precision. They are often used for cutting thick or hard materials that would be difficult to cut with manual or mechanical shears.

- Mechanical Shears: Mechanical shears rely on mechanical power, such as a flywheel or crankshaft, to drive the cutting blade. While less common than hydraulic or electric shears, mechanical shears can be cost-effective for certain applications and may offer higher cutting speeds.

VIGERT 16X3200 Shearing Machines vary in size and capacity, with some designed for small-scale workshops and others capable of cutting large sheets or plates in industrial settings. They are essential tools for metal fabrication, offering efficient and precise cutting capabilities for a wide range of applications.

Why Choose VIGERT?

VIGERT is a professional used metalworking machine dealer in China for many years, our productions have been sold to over 100 countries in the world!

Reviews

There are no reviews yet.