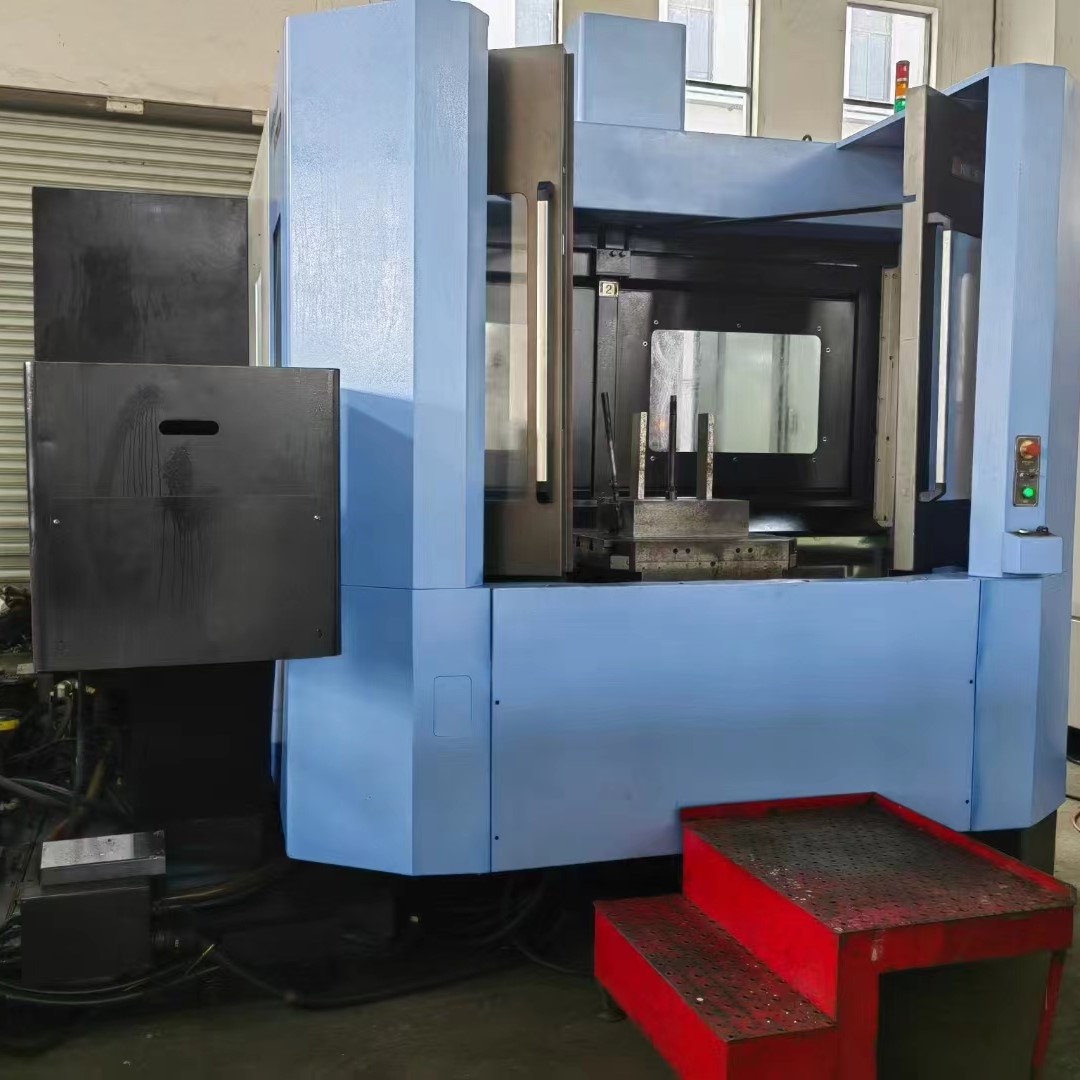

Used DOOSAN HM630 Steady Horizontal Machining Center With 31i-A For Sale

| Condizione |

85% Nuovo |

|---|---|

| Marca |

DOOSAN |

| Anno MFG |

2018 |

| Origine |

COREA |

| Funzione |

Centro di lavoro |

| Modello |

HM630 |

| Metodo di pagamento |

T/T |

| Termine di prezzo |

EXW |

| Garanzia |

Un anno |

HM630 Steady Horizontal Machining Center

A HM630 Steady Horizontal Machining Center (HMC) is a type of machine tool used in manufacturing and machining processes. It is designed for precision machining of various materials, typically metals, by removing material from a workpiece to create intricate shapes, holes, and surfaces. The primary distinguishing feature of an HMC is its horizontally oriented spindle, which is parallel to the worktable.

Key characteristics and features of a Horizontal Machining Center include:

- Horizontal Spindle Orientation: On the basis of HM630 Steady Horizontal Machining Center. The spindle of the machine is oriented horizontally, allowing the cutting tool to approach the workpiece from various angles and directions. This can be advantageous for specific machining operations and chip evacuation.

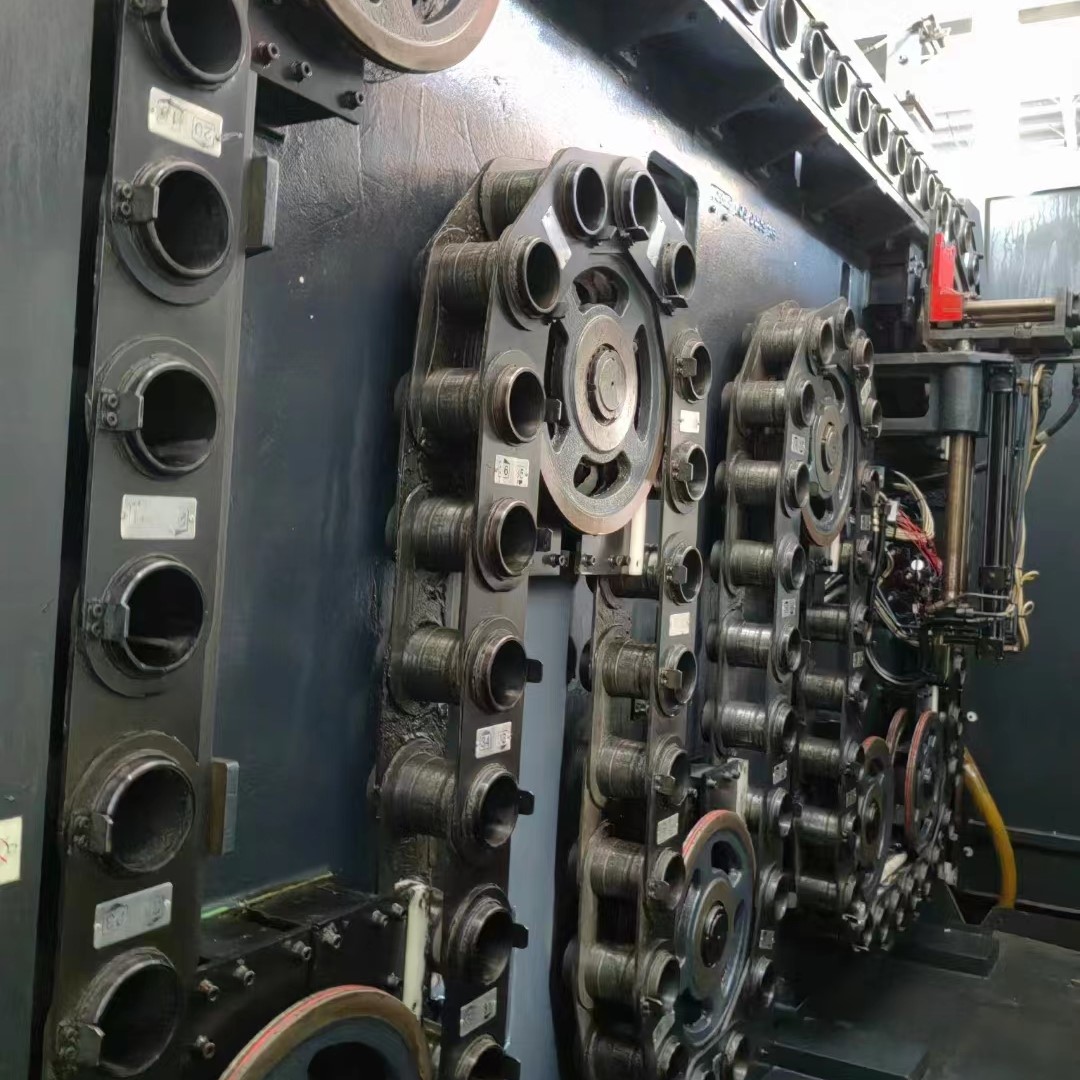

- Capacità multiasse: On the basis of HM630 Steady Horizontal Machining Center. Many modern HMCs are equipped with multiple axes, typically ranging from three to five axes. This enables the machine to perform complex machining operations on multiple sides of the workpiece without repositioning.

- Alta precisione: On the basis of HM630 Steady Horizontal Machining Center. HMCs are designed for high-precision machining, with the ability to achieve tight tolerances and fine surface finishes. This is essential for industries that require precise components.

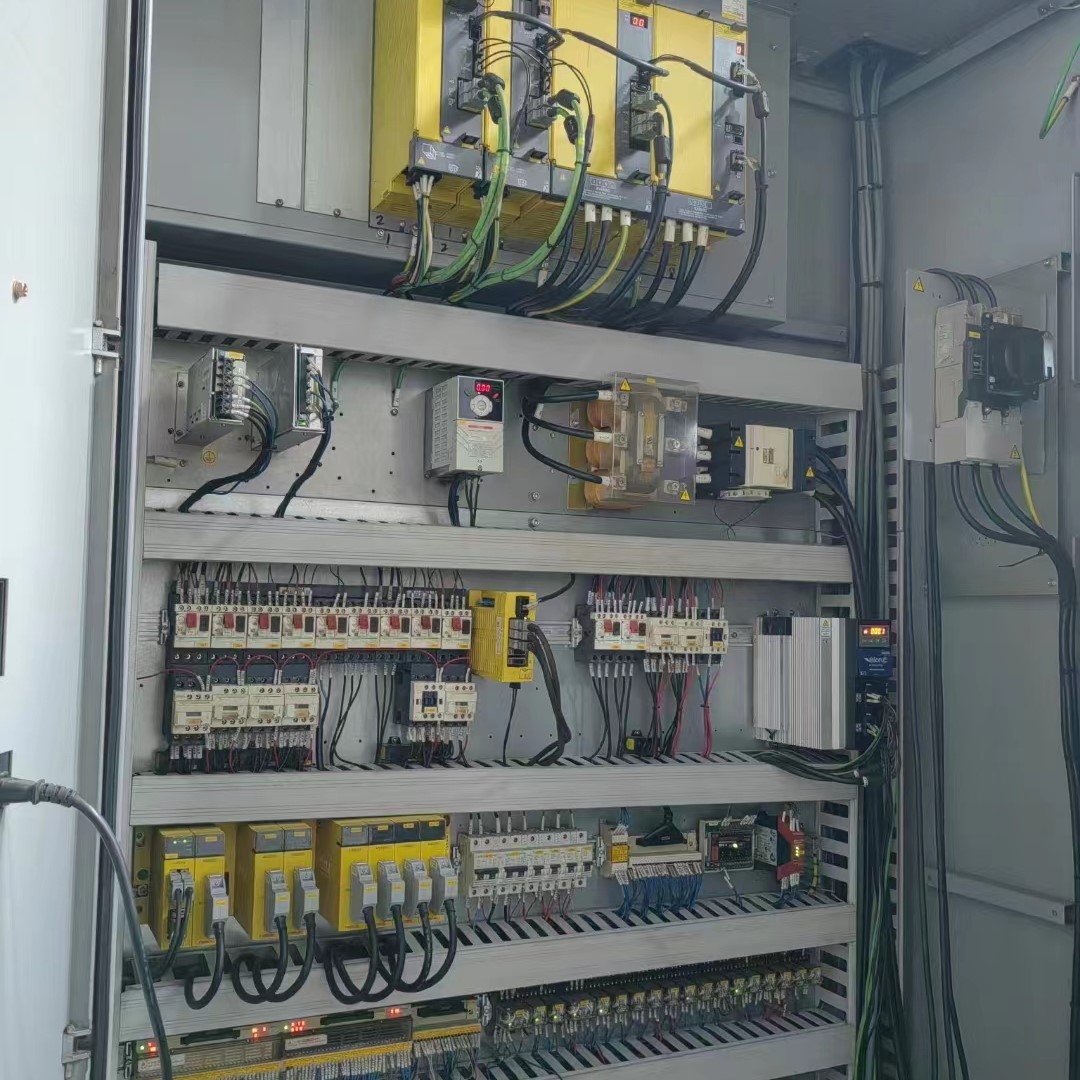

- Automazione: HMCs can often be integrated into automated manufacturing systems. They can feature automatic tool changers, pallet changers, and robotic systems that enhance productivity and reduce downtime.

- Versatilità: HMCs can handle a wide variety of machining tasks, from roughing to finishing. They can work with different materials, including metals, plastics, and composites.

- Gestione dei chip: The horizontal orientation of the spindle aids in chip evacuation. Chips produced during machining tend to fall away from the work area, reducing the risk of interference and improving overall efficiency.

- Stabilità: The horizontal spindle orientation can provide better stability, particularly for heavy or large workpieces. This contributes to improved surface finish and dimensional accuracy.

- Gestione del refrigerante: The design of HMCs often allows for efficient coolant flow, aiding in cooling and lubrication during machining.

- Workpiece Handling: HMCs can accommodate various workpiece sizes and shapes due to their flexible workholding setups. Pallet changers can further streamline workpiece loading and unloading.

Perché scegliere VIGERT?

VIGERT è un rivenditore di macchine per la lavorazione dei metalli usate professionale in Cina da molti anni, le nostre produzioni sono state vendute in oltre 100 paesi nel mondo!

Recensioni

Ancora non ci sono recensioni.