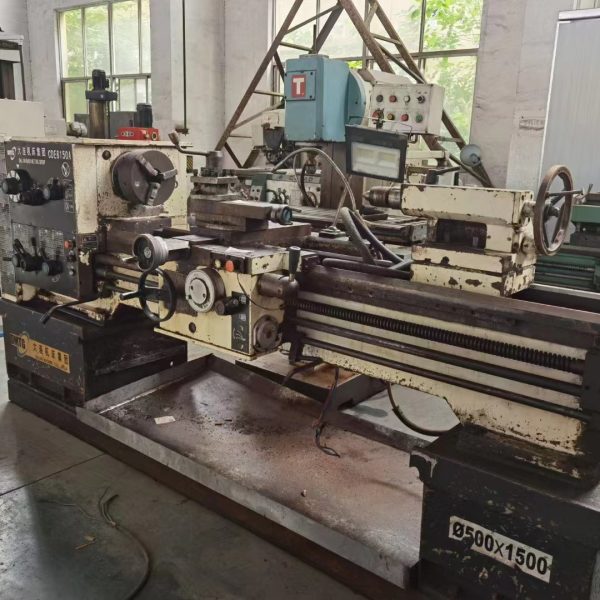

Tornio di precisione DMTG GM6125 usato in vendita

| Peso | 999 kg |

|---|---|

| Condizione |

90% Nuovo |

| Origine |

Cina |

| Metodo di pagamento |

LC ,T/T |

| Termine di prezzo |

EXW |

| Garanzia |

Un anno |

| Marca |

DMTG |

| Anno MFG |

2018 |

| Modello |

GM6125 |

| Funzione |

Fresatura |

As of my last knowledge update in September 2021, I don’t have specific information on a “GM6125 Precision Lathe.” However, I can provide you with a general description of what a precision lathe might entail:

A precision lathe is a specialized machine tool designed for accurate and high-quality machining of workpieces with tight tolerances and fine finishes. While I don’t have information on the specific GM6125 model, here’s a general idea of what a precision lathe might include:

Key Features and Characteristics (Typical for Precision Lathes):

- High Accuracy: GM6125 Precision Lathe are known for their ability to produce parts with very tight tolerances. These lathes are engineered to minimize errors and deviations during machining.

- Costruzione rigida: GM6125 Precision Lathe structure is designed to be rigid and stable, reducing vibrations and enhancing precision during cutting operations.

- Sistema di controllo avanzato: GM6125 Precision Lathe often feature CNC (Computer Numerical Control) systems, allowing for accurate and repeatable machining processes.

- Capacità multiasse:might offer multi-axis machining, including X, Y, Z, and sometimes additional rotational axes, enabling complex machining operations.

- Fine Feed Control: GM6125 Precision Lathe allow for very fine feed rate adjustments, ensuring the precise removal of material.

- High-Quality Spindle: The spindle is a crucial component, and precision lathes might have high-quality spindles with low runout to maintain accuracy.

- Tool Holders and Tooling: These lathes typically support a variety of tool holders and cutting tools suitable for achieving intricate details.

- Tailstock and Chuck: Precision lathes may feature precise tailstocks and chucks to securely hold and accurately position workpieces.

- Sistema di raffreddamento: To manage heat and chips during machining, precision lathes often have efficient coolant systems.

- Digital Readouts: Some lathes have digital readouts that provide real-time measurements, aiding in precise machining.

- Applicazioni: Precision lathes are commonly used in industries where tight tolerances are critical, such as aerospace, medical device manufacturing, electronics, and more.

- Tool Presetters: Some models may have tool presetters to accurately measure and set tools before machining, reducing setup times.

Perché scegliere VIGERT?

VIGERT è un rivenditore di macchine per la lavorazione dei metalli usate professionale in Cina da molti anni, le nostre produzioni sono state vendute in oltre 100 paesi nel mondo!

Recensioni

Ancora non ci sono recensioni.