5 najważniejszych zalet stosowania giętarki panelowej CNC do blachy

When it comes to modern sheet metal fabrication, CNC panel benders are revolutionizing the way manufacturers handle precision bending. Unlike traditional press brakes, panel benders use advanced automation and intelligent control systems to bend sheet metal panels with exceptional speed, consistency, and flexibility. Whether you are producing electrical enclosures, cabinets, HVAC panels, or architectural facades, a CNC panel bender can dramatically boost your efficiency and product quality.

In this article, we will explore the top 5 advantages of using a CNC panel bender for sheet metal processing and provide a detailed breakdown of how this equipment can transform your production floor in both small and large manufacturing environments.

1. Unmatched Bending Speed and Productivity

One of the most significant benefits of CNC panel benders is their exceptional bending speed. Unlike conventional press brakes that require manual repositioning, realignment, and multiple tool changes, panel benders automate the entire bending sequence. The sheet metal is clamped in place, and a programmable bending blade performs each bend in sequence, rotating and adjusting automatically between bends.

This highly automated cycle dramatically reduces manual handling time, setup changes, and human error. CNC panel benders are particularly useful in Just-In-Time (JIT) production environments, where efficiency, speed, and repeatability are critical.

Real-World Benefits of Increased Speed:

- Shorter cycle times: Each panel is bent in seconds instead of minutes.

- Minimal downtime: Rapid changeover between part types with stored programs.

- High output: Suitable for high-volume production and custom batch runs alike.

- Quick setup: No need for frequent tool changes between bends.

Panel benders allow manufacturers to meet tight production schedules while delivering consistent results across hundreds or thousands of units.

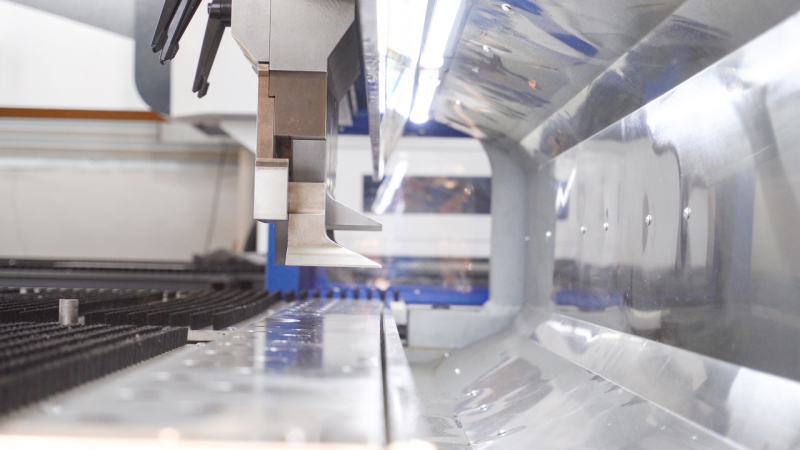

2. Superior Bending Consistency and Accuracy

Precision is paramount in any sheet metal operation. A CNC panel bender ensures accurate and repeatable bending for every single part, regardless of operator skill level or production volume. Traditional press brakes, while versatile, depend significantly on the operator’s expertise and manual calibration for each job, which can introduce variation.

With a panel bender, computer-controlled settings manage every motion of the blade, clamps, and sheet rotation. Sensors detect material properties and automatically compensate for springback and deformation, maintaining tight tolerances throughout the production process.

Consistency That Boosts Quality:

- Integrated angle measuring systems: Guarantee accuracy for each bend.

- Material sensing: Adjusts for sheet thickness or hardness variations in real time.

- Error elimination: No more guesswork or trial-and-error.

- Perfect for symmetrical parts: High consistency in enclosures, drawer fronts, and cabinet panels.

This level of precision is especially valuable when manufacturing parts that must fit together perfectly or where cosmetic finish is important, such as in appliance or electrical enclosure production.

3. Greater Design Flexibility and Capability

CNC panel benders support a vast range of bending operations, offering flexibility that is difficult to achieve with traditional press brakes. Unlike press brakes that require individual tools for each bend angle or flange size, panel benders use universal tooling that can create different geometries without changeover.

With advanced programming software, manufacturers can produce complex panel shapes that include multiple radii, closed hems, shallow boxes, offset flanges, and variable-height returns—all within a single cycle.

What Makes Panel Benders Versatile:

- Universal tooling: Handles different geometries without changeover.

- Multi-radius forming: Ideal for panels with varying profiles.

- Pre-coated and sensitive materials: Panel benders avoid surface marring.

- Different materials: Works with stainless steel, aluminum, galvanized, and painted sheets.

By removing tooling restrictions, CNC panel benders encourage innovation in part design. Engineers can design more complex, functional, and aesthetic parts without being limited by forming capabilities.

4. Reduced Operator Dependency and Labor Costs

One of the biggest challenges in manufacturing today is the shortage of skilled labor. CNC panel benders offer a compelling solution by reducing reliance on highly trained press brake operators. Their intuitive software and automated material handling systems allow even entry-level staff to produce high-quality parts after minimal training.

This democratization of sheet metal bending reduces labor bottlenecks and allows your experienced team members to focus on higher-value tasks such as design, quality control, or maintenance.

How Panel Benders Reduce Operator Burden:

- Graphical programming interfaces: Easy to learn and use.

- Job storage: Save hundreds of part programs for quick recall.

- Minimal manual handling: Automatic clamping, rotation, and positioning.

- Ergonomic operation: Less lifting, reducing fatigue and injury risk.

In regions facing skilled labor shortages, or for companies expanding rapidly, panel benders make it easier to scale production while maintaining high quality.

5. Lower Total Cost of Ownership (TCO)

Although the upfront cost of a CNC panel bender may appear higher than that of a press brake, the overall total cost of ownership is often significantly lower. Faster production, fewer reworks, less scrap, and lower labor requirements all contribute to long-term cost savings.

Additionally, the universal tooling used in panel benders drastically reduces tooling inventory, change over time, and maintenance costs. Many panel benders are designed for 24/7 operation with minimal downtime, and remote diagnostics further help reduce service interruptions.

Cost-Effective Factors to Consider:

- Fewer scrap parts: Thanks to precision bending and reduced operator error.

- Lower rework costs: Higher consistency means less quality control intervention.

- Energy savings: Servo-electric drives consume less power than hydraulic systems.

- Fewer tool purchases: Universal tooling supports multiple bend types.

- Higher machine uptime: Built-in diagnostics and remote support minimize maintenance downtime.

The ROI on a CNC panel bender can often be realized within a few years, especially in facilities with high mix/low volume or JIT production models.

Additional Benefits: Safety, Sustainability, and Scalability

Beyond speed, precision, and cost, panel benders offer a number of secondary benefits that are increasingly important in modern manufacturing.

Safety Improvements:

- Fully enclosed bending area with safety interlocks

- Reduced manual handling lowers injury risk

- Automatic part ejection keeps operator hands away from tooling

Sustainability and Environmental Efficiency:

- Many machines feature energy-efficient motors and standby modes

- Lower waste and scrap rates reduce raw material usage

- Cleaner operation with electric drives (compared to hydraulic systems)

Scalable Growth Potential:

- Integrates easily into smart factory systems and MES platforms

- Supports robotic loading/unloading for lights-out manufacturing

- Software updates and upgrades extend machine lifespan

These extended benefits make panel benders a strong investment not just for present needs, but also for future automation and sustainability goals.

Applications Across Industries

CNC panel benders are used across a variety of sectors where precision sheet metal fabrication is essential:

- Electrical enclosures and switchgear panels

- HVAC units and ventilation systems

- Furniture components, including drawer fronts and cabinet doors

- Appliance housing such as washing machines and ovens

- Części samochodowe like battery trays and structural reinforcements

- Architectural elements including decorative panels and metal facades

Their versatility, speed, and precision make them valuable assets in both job shop environments and high-throughput automated lines.

Wniosek

If your business involves regular production of sheet metal panels, investing in a CNC panel bender can lead to measurable improvements in speed, accuracy, flexibility, and cost savings. By replacing manual operations and simplifying complex bend sequences, these machines empower manufacturers to stay competitive in an increasingly demanding market.

From lower scrap rates to faster lead times and reduced reliance on skilled labor, the benefits of CNC panel benders are significant and far-reaching. As product designs become more complex and customer expectations rise, upgrading to a CNC panel bender could be the key to unlocking new levels of efficiency, scalability, and profitability in your fabrication process.

Whether you’re expanding your production line, starting a new shop, or simply modernizing your capabilities, a CNC panel bender offers long-term advantages that make it one of the most worthwhile investments in sheet metal manufacturing today.