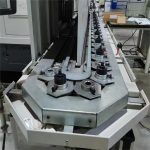

Używana frezarka obwiedniowa CNC LIEBHERR LC180 z 840D na sprzedaż

| Marka |

VIGERT |

|---|---|

| Stan: schorzenie |

95% Nowość |

| Funkcjonować |

Frezowanie kół zębatych |

| Rok MFG |

2021 |

| Model |

LC180 |

| Początek |

Niemcy |

| Metoda płatności |

T/T |

| Termin cenowy |

EXW |

| Gwarancja |

Rok |

Obróbka frezarska CNC z przekładnią 840D

On the basis of CNC Gear Hobbing Machine With 840D. A CNC Gear Hobbing Machine with the Siemens 840D control system refers to a computer numerical control (CNC) machine used for the process of gear hobbing, which is a common method for producing gears. The “840D” is a specific model of CNC control system developed by Siemens, known for its advanced capabilities in controlling machine tools and industrial automation processes. Here’s a breakdown of the components and concepts involved:

1. CNC Gear Hobbing Machine: On the basis of CNC Gear Hobbing Machine With 840D. A gear hobbing machine is a specialized machine tool used for manufacturing gears. It uses a cutting tool called a hob to create gear teeth by gradually cutting into the workpiece material. Gear hobbing machines can produce various types of gears, including spur gears, helical gears, and worm gears.

2. Siemens 840D Control System: The Siemens 840D is a widely used CNC control system in the manufacturing industry. It provides the software and hardware necessary to control various types of machine tools, including gear hobbing machines. The 840D control system offers features such as high-speed machining, advanced toolpath programming, and support for various programming languages.

3. CNC (Computer Numerical Control): CNC refers to the automation of machine tools through the use of computers to execute pre-programmed sequences of commands. In the context of a gear hobbing machine, CNC technology allows for precise control over the cutting process, ensuring accurate gear profiles and minimizing operator intervention.

4. Gear Hobbing Process: On the basis of CNC Gear Hobbing Machine With 840D. The gear hobbing process involves the use of a rotating hob, which has cutting teeth that gradually cut into the workpiece material to form gear teeth. The workpiece is typically mounted on a rotating spindle, and the hob’s motion is synchronized with the workpiece rotation to achieve the desired gear geometry.

5. 840D Control Features: On the basis of CNC Gear Hobbing Machine With 840D. The Siemens 840D control system offers a range of features tailored to gear hobbing machines. These features may include:

- Axis Control: Precise control over the movement of the machine’s axes, ensuring accurate hob positioning.

- Toolpath Programming: Generating and controlling the toolpath that the hob follows to create the gear teeth.

- Speed and Feed Control: Adjusting the cutting speed and feed rate for optimal cutting performance.

- Interpolation: Calculating complex toolpath motions to create intricate gear profiles.

- Monitoring and Diagnostics: Real-time monitoring of machine performance and diagnostics to detect and address issues.

Dlaczego warto wybrać firmę VIGERT?

VIGERT jest od wielu lat profesjonalnym sprzedawcą używanych maszyn do obróbki metali w Chinach, nasze produkcje zostały sprzedane do ponad 100 krajów na świecie!

Opinie

W razie nie ma opinii o produkcie.