Używane dwustanowiskowe centrum obróbcze UNION KC150/1 do poziomego wytaczania i frezowania na sprzedaż

| Waga | 999 kg |

|---|---|

| Stan: schorzenie |

90% Nowość |

| Początek |

Chiny |

| Metoda płatności |

LC ,T/T |

| Termin cenowy |

EXW |

| Gwarancja |

Rok |

| Marka |

VIGERT |

| Funkcjonować |

Przemiał |

| Rok MFG |

2021 |

| Model |

KC150/1 |

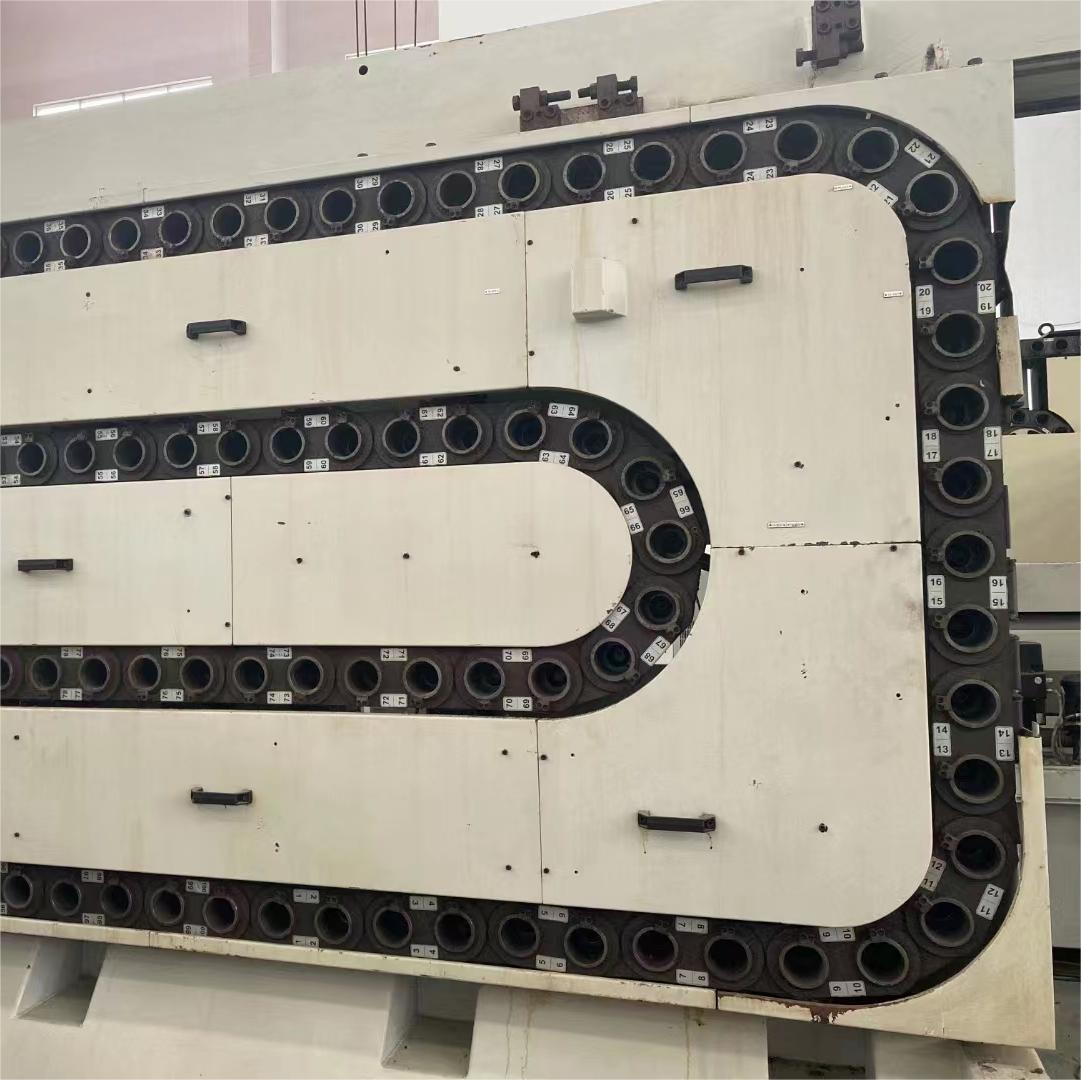

A Double Station Machining Center is an advanced industrial machine tool designed to increase productivity by providing two separate workstations within a single machine. This configuration allows for parallel processing, where one workstation can perform machining operations while the other is loaded/unloaded, increasing efficiency and reducing downtime. Double Station Machining Centers are used in various manufacturing industries to optimize production and maximize output. Here’s a description of the key features and functions of a Double Station Machining Center:

- Dual Workstations: The most distinctive feature of a Double Station Machining Center is its two workstations. Each workstation consists of a combination of a workholding fixture, cutting tools, and other machining equipment.

- Sterowanie CNC: Similar to other machining centers, a Double Station Machining Center is equipped with a CNC control system that manages the operations of both workstations. CNC control ensures precision, consistency, and automation of machining processes.

- Możliwość obsługi wielu osi: Each workstation typically has multi-axis movement, allowing for a variety of machining processes such as milling, drilling, tapping, and more. The number of axes depends on the complexity of the machine’s design.

- Zmieniacze narzędzi: Both workstations may feature automatic tool changers (ATCs) that allow for tool changes without manual intervention. This reduces downtime between machining operations.

- Obsługa materiałów: Double Station Machining Centers often include material handling systems, such as robotic arms or conveyors, to load and unload workpieces from one station to the other. This automation further enhances efficiency.

- Simultaneous Processing: While one workstation is machining a workpiece, the other can be loaded with a new workpiece or undergoing other preparation processes. This simultaneous processing minimizes idle time and increases throughput.

- Wysoka produktywność: The parallel processing capability of a Double Station Machining Center significantly increases productivity compared to traditional single-station machining centers.

- Flexible Manufacturing: The dual workstation design allows for flexibility in manufacturing processes. Different workpieces can be set up on each workstation, accommodating various part sizes and complexities.

- CAM Software Integration: Computer-Aided Manufacturing (CAM) software generates the toolpaths for both workstations, enabling precise and efficient machining operations. CAM-generated G-code is used by the CNC control system.

- Industry Applications: Double Station Machining Centers find applications in industries such as automotive, aerospace, electronics, and general manufacturing. They are ideal for high-volume production of components with repeatable machining processes.

- Personalizacja: The machining process and tooling for each workstation can be tailored to meet the specific requirements of the workpieces being produced.

- Kontrola jakości: Some models may include inspection and measurement systems to ensure the accuracy and quality of machined components.

Dlaczego warto wybrać firmę VIGERT?

VIGERT jest od wielu lat profesjonalnym sprzedawcą używanych maszyn do obróbki metali w Chinach, nasze produkcje zostały sprzedane do ponad 100 krajów na świecie!

Opinie

W razie nie ma opinii o produkcie.