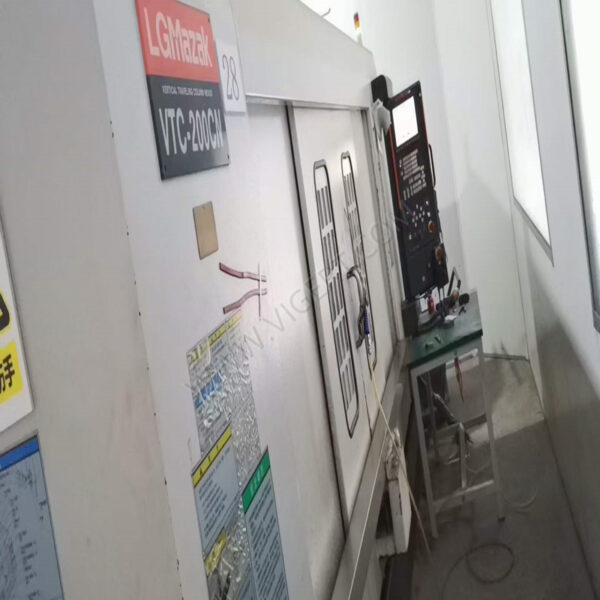

Used VIGERT NBP-1000A CNC Machining Center For Sale

| Waga | 999 kg |

|---|---|

| Stan: schorzenie |

90% Nowość |

| Rok MFG |

2011 |

| Początek |

Chiny |

| Metoda płatności |

LC ,T/T |

| Termin cenowy |

EXW |

| Marka |

VIGERT |

| Gwarancja |

Rok |

| Model |

EV850 |

| Funkcjonować |

Przemiał |

NBP-1000A CNC Machining Center. I can provide a general description of what a CNC machining center typically involves, and you can use this as a reference for the NBP-1000A model.

NBP-1000A CNC Machining Center. A CNC machining center, like the NBP-1000A (assuming this is a specific model), is a sophisticated and automated machine tool used for precision machining and manufacturing of various materials, including metals, plastics, and composites. Here’s a breakdown of the key components and functionalities commonly associated with CNC machining centers:

- Control System (CNC): NBP-1000A CNC Machining Center. The CNC system is the central control unit that interprets computer-aided design (CAD) models and translates them into precise movements and operations. Operators use the CNC interface to input machining parameters, tool paths, and other necessary instructions.

- Spindle and Cutting Tools: NBP-1000A CNC Machining Center. The machining center is equipped with a spindle motor capable of high-speed rotations. Various cutting tools (end mills, drills, etc.) are mounted on the spindle to perform cutting, drilling, milling, and other machining operations.

- Zmieniacz narzędzi: A tool changer automatically selects and replaces tools as needed during the machining process, optimizing efficiency and minimizing downtime.

- Stół do pracy: The worktable is where the workpiece is securely clamped for machining. It can move along different axes (X, Y, Z) to position the workpiece accurately under the cutting tools.

- Coolant and Lubrication System: A coolant system is integrated to cool the cutting tools and workpiece during machining, preventing overheating and ensuring a better surface finish. Additionally, a lubrication system is used to reduce friction and wear on moving parts.

- Control Panel and Display: The control panel typically includes a user interface, buttons, and a display for operators to input commands, monitor the machining process, and make adjustments.

- Funkcje bezpieczeństwa: Modern machining centers are equipped with safety features such as emergency stops, protective enclosures, and interlocks to ensure safe operation for operators.

- Dokładność i precyzja: CNC machining centers are designed to achieve high levels of accuracy and precision, meeting tight tolerances required for various applications.

Dlaczego warto wybrać firmę VIGERT?

VIGERT jest od wielu lat profesjonalnym sprzedawcą używanych maszyn do obróbki metali w Chinach, nasze produkcje zostały sprzedane do ponad 100 krajów na świecie!

Opinie

W razie nie ma opinii o produkcie.