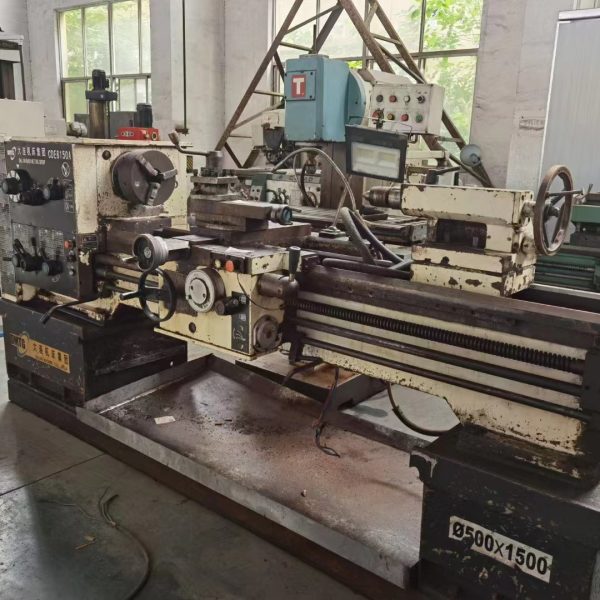

Used PRECION CW61180L Lathe For Sale

| Weight | 999 kg |

|---|---|

| Condition |

90% New |

| MFG Year |

2005 |

| Origin |

China |

| Payment Method |

LC ,T/T |

| Brand |

PRECION |

| Price Term |

EXW |

| Function |

Milling |

| Warranty |

One Year |

| Model |

CW61180L |

The CW61180L lathe is a specific model of lathe machine utilized in machining and manufacturing processes for turning and shaping cylindrical workpieces. The model number CW61180L provides information about the lathe’s specifications, capabilities, and potential features.

General Description:

The CW61180L lathe is likely a heavy-duty, precision lathe designed to handle large and long workpieces. It is ideal for various industrial applications, such as in metalworking, aerospace, automotive, and other manufacturing sectors where precision turning operations are essential.

Potential Features:

- Lathe Type:

- The CW61180L is a large, heavy-duty lathe, likely designed for handling substantial workpieces with long lengths and diameters.

- Bed and Structure:

- Constructed with a robust bed made of high-quality cast iron or steel to provide stability and rigidity for precise machining.

- Spindle and Chuck:

- CW61180L Lathe. Equipped with a spindle and chuck mechanism for holding and rotating the workpiece, facilitating turning and machining operations.

- Headstock and Tailstock:

- CW61180L Lathe. Features a headstock that houses the spindle and other drive mechanisms, while the tailstock provides support for longer workpieces.

- Tooling and Tool Posts:

- Likely includes tooling options such as tool posts and tool holders for mounting and using cutting tools during turning operations.

- Variable Speed Control:

- Provides adjustable spindle speeds to accommodate various materials and machining requirements, allowing for versatility in operations.

- Automatic Feed and Thread Cutting:

- Capable of automatic feed control and thread cutting, enhancing efficiency and accuracy in turning operations.

- Workholding Devices:

- Utilizes workholding devices like chucks, collets, or other fixtures to secure the workpiece during turning.

- Digital Readouts (DRO):

- Potentially includes digital readouts displaying the position of the tool, workpiece dimensions, and other relevant data for improved accuracy.

- Coolant System:

- May have a coolant system to dissipate heat and improve cutting efficiency and tool life during machining.

- Control System:

- Equipped with a control system, which could range from manual controls to computer numerical control (CNC) for automated and precise machining.

- Safety Features:

- Includes essential safety features such as emergency stop buttons, protective enclosures, and safety interlocks to ensure safe operation.

Why Choose VIGERT?

VIGERT is a professional used metalworking machine dealer in China for many years, our productions have been sold to over 100 countries in the world!

Reviews

There are no reviews yet.