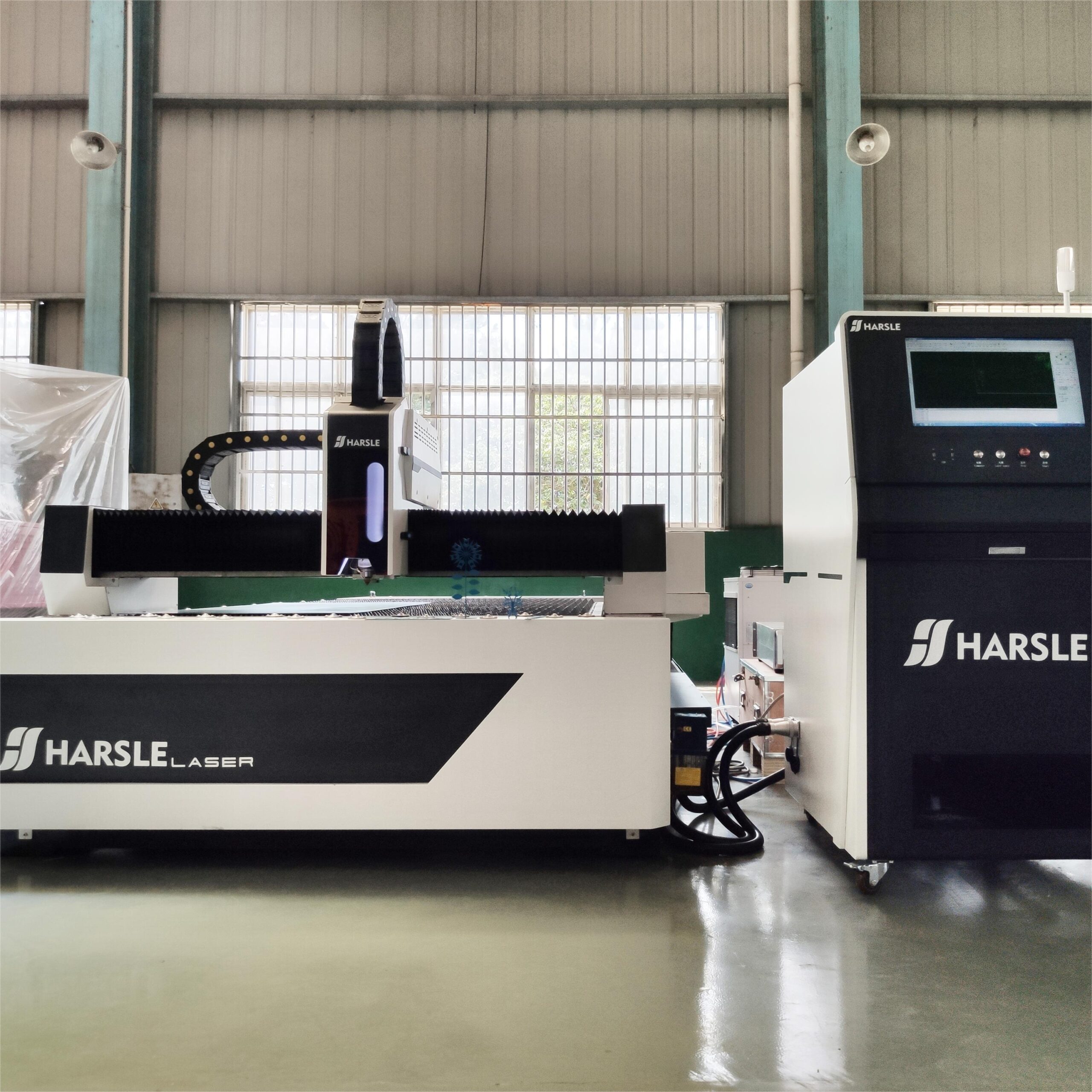

Used HARSLE HS-1000W3015 Laser Cutting Machine With RAYCUS For Sale

| Weight | 999 kg |

|---|---|

| Dimensions | 1000 × 3000 cm |

| Brand |

HARSLE |

| Condition |

99% New |

| Function |

Cutting |

| MFG Year |

2024 |

| Model |

HS-1000W3015 |

| Origin |

China |

| Payment Method |

LC ,T/T |

| Price Term |

EXW |

| Warranty |

One Year |

10 in stock

A HARSLE HS-1000W3015 Laser Cutting Machine is a tool used in manufacturing and fabrication processes to precisely cut materials using a high-powered laser beam. It offers several advantages over traditional cutting methods, including high precision, speed, and versatility.HARSLE HS-1000W3015 Laser Cutting Machine

Here’s a breakdown of the main components and functionalities of a typical laser cutting machine:

- Laser Source: The laser source generates the high-intensity beam of coherent light used for cutting. Common types of lasers used in laser cutting machines include CO2 lasers and fiber lasers. The choice of laser type depends on factors such as the material being cut, the thickness of the material, and the desired cutting speed.

- Beam Delivery System: The beam delivery system consists of mirrors and lenses that guide and focus the laser beam onto the material being cut. It ensures that the laser energy is concentrated at the desired location with high precision.

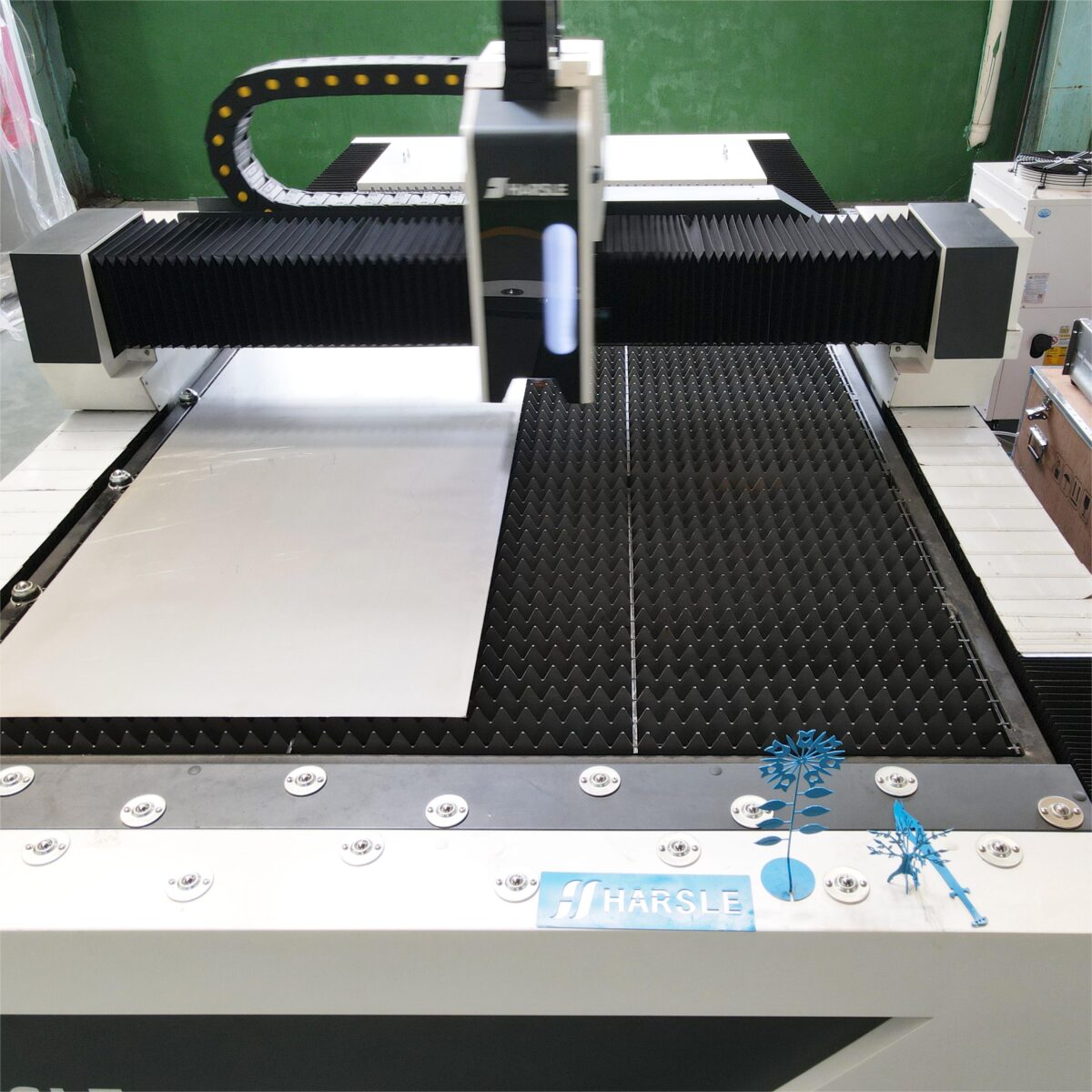

- Workpiece Handling System: The workpiece handling system holds and positions the material to be cut in the correct orientation relative to the laser beam. It may include a cutting table, conveyor system, or robotic arm for automated material handling.

- Control System: A control system manages the operation of the laser cutting machine, including setting parameters such as laser power, cutting speed, and focal length. It may also include software for designing cutting paths, importing CAD (Computer-Aided Design) files, and nesting parts to optimize material usage.

- Cutting Head: The cutting head directs the laser beam onto the material and may include features such as autofocus capability, capacitive height sensing, and collision protection. It may also contain a nozzle for assisting gas delivery, which helps to blow away molten material and maintain a clean cutting edge.

- Gas Supply System: In laser cutting processes, a assist gas (such as oxygen, nitrogen, or air) is often used to enhance the cutting process. The gas supply system delivers the appropriate gas to the cutting area at controlled flow rates.

- Exhaust System: Laser cutting generates smoke, fumes, and debris, so an exhaust system is essential to remove these byproducts from the cutting area and maintain a safe working environment. The exhaust system may include filters to remove particulates and gases before venting to the outside.

HARSLE HS-1000W3015 Laser Cutting Machines are used in various industries, including automotive, aerospace, electronics, signage, jewelry making, and medical device manufacturing. They can cut a wide range of materials, including metals, plastics, wood, ceramics, and composites, with high precision and minimal heat-affected zones. Laser cutting is particularly well-suited for intricate designs, small features, and rapid prototyping applications.

Why Choose VIGERT?

VIGERT is a professional used metalworking machine dealer in China for many years, our productions have been sold to over 100 countries in the world!

Reviews

There are no reviews yet.