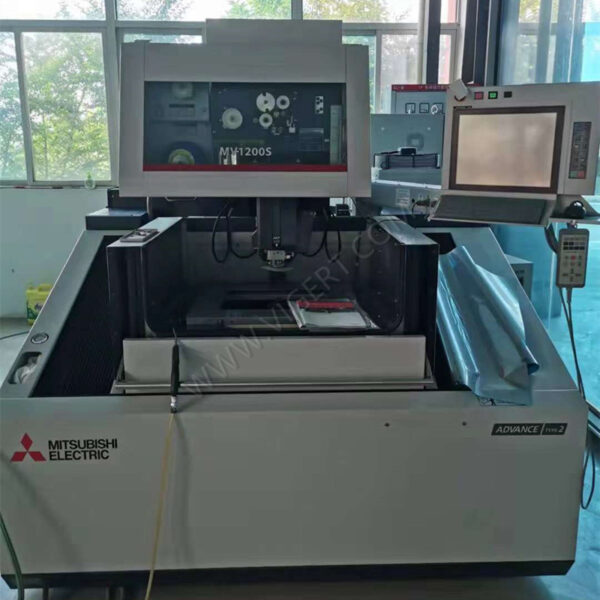

Used SODICK AQ360LXs Wire Erosion For Sale

| Weight | 999 kg |

|---|---|

| Dimensions | 2500 × 3000 × 3000 cm |

| Brand |

SODICK |

| Condition |

95% New |

| Function |

Wire Erosion |

| MFG Year |

2017 |

| Model |

AQ360LS |

| Origin |

China |

| Payment Method |

LC ,T/T |

| Price Term |

EXW |

| Warranty |

One Year |

The Used SODICK AQ360LXs Wire Erosion is an advanced machining tool designed for high-precision cutting of intricate shapes and contours in electrically conductive materials.

Here’s a detailed description of the Used SODICK AQ360LXs Wire Erosion:

- High Precision Cutting: The AQ360LXs utilizes a fine wire electrode and controlled electrical discharges to precisely erode material from the workpiece. This method allows for intricate features and tight tolerances to be achieved, making it suitable for applications where precision is critical.

- Linear Motor Drives: Similar to other Sodick EDM machines, the Used SODICK AQ360LXs Wire Erosion is likely equipped with linear motor drives. These drives provide high-speed and high-accuracy movement of the machine’s axes, ensuring superior cutting performance and surface finish.

- Large Workpiece Capacity: The AQ360LXs is designed with a large workpiece capacity, allowing it to handle relatively large components. This capability makes it versatile for a wide range of applications across various industries, including aerospace, automotive, mold and die making, and medical device manufacturing.

- Advanced CNC Control System: The machine features an advanced CNC control system that enables precise programming and control over the machining process. Operators can input precise cutting parameters and monitor the machining process in real-time, ensuring optimal results.

- Automatic Wire Threader: Wire EDM machines often feature automatic wire threading systems, which streamline setup and reduce downtime. The AQ360LXs is likely equipped with such a system, allowing for quick and efficient wire changes when necessary.

- Advanced Dielectric System: The machine is equipped with an advanced dielectric system that flushes away debris and maintains a stable machining environment. This ensures optimal cutting conditions and extends the life of the electrodes and workpiece.

- High Efficiency: Wire EDM is known for its high efficiency, as it can cut through even the toughest materials with ease. The Sodick AQ360LXs is designed to maximize productivity while maintaining exceptional precision, making it a valuable asset for manufacturing operations.

- Quality and Reliability: Sodick is renowned for producing high-quality EDM machines known for their reliability and durability. The AQ360LXs is likely built with robust components and materials to withstand the demands of industrial machining environments, ensuring long-term performance and minimal downtime.

In summary, the Used SODICK AQ360LXs Wire Erosion machine offers high precision cutting capabilities, large workpiece capacity, advanced CNC control systems, and high efficiency, making it an ideal solution for manufacturers requiring precise and efficient machining of electrically conductive materials.

Why Choose VIGERT?

VIGERT is a professional used metalworking machine dealer in China for many years, our productions have been sold to over 100 countries in the world!

Reviews

There are no reviews yet.