Used MAKINO F5 Machining Center For Sale

| Brand |

MAKINO |

|---|---|

| Condition |

95% New |

| Function |

Cutting |

| MFG Year |

2016 |

| Model |

F5 |

| Price Term |

EXW |

| Origin |

Japan |

| Payment Method |

T/T |

| Warranty |

One Year |

10 in stock

A Used MAKINOF5 Machining Center , also known as a CNC (Computer Numerical Control) machining center, is a highly automated manufacturing machine used for various machining operations, such as milling, drilling, tapping, and other processes. It is a computer-controlled machine tool that can perform complex and precise cuts on various materials, including metal, plastic, and composites.

Here are key features and components of a typical Used MAKINO F5 Steady Machining Center :

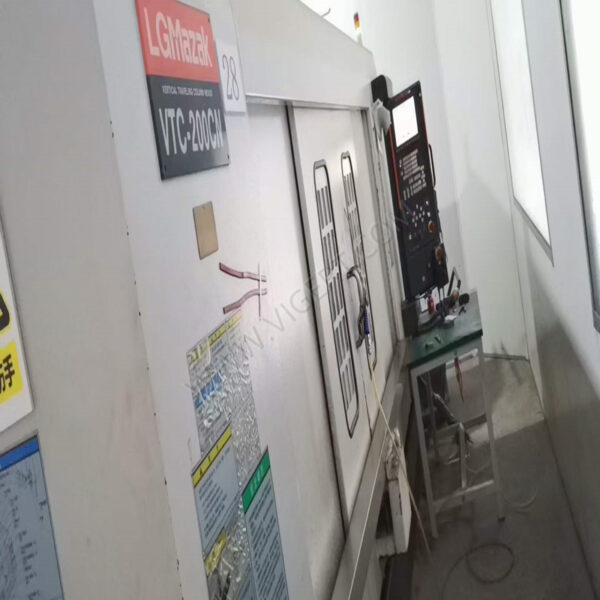

- Machine Structure:

- F5 Machining Center. The machine’s structure comprises a bed or base, columns, a spindle, and a worktable. The bed provides stability and support for the machine components.

- Spindle:

- F5 Machining Center. The spindle is a critical component that holds and rotates the cutting tool. It’s responsible for the actual machining processes, such as cutting, drilling, and milling.

- Tool Changer:

- Machining centers often have an automatic tool changer (ATC) that allows for quick and automated changes of cutting tools during the machining process. This enhances efficiency and minimizes downtime.

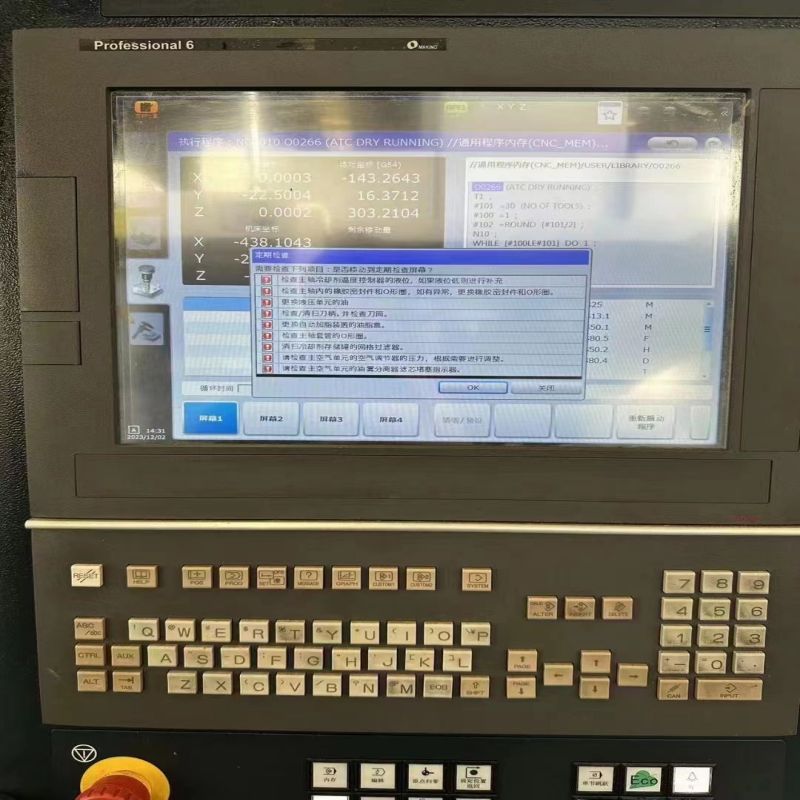

- Control System:

- The control system includes a computer, software, and a control panel that enables the operator to program and control the machining operations. CNC programming dictates the tool’s path, speed, and depth of cut.

- Worktable:

- The worktable holds the workpiece in place during machining. It can move in different directions (X, Y, and Z axes) to position the workpiece for machining at various angles and orientations.

- Axes:

- F5 Machining center typically have three or more axes (X, Y, Z) that allow for movement and positioning of the cutting tool in three-dimensional space.

- Coolant System:

- F5 Machining generates heat, so a coolant system is often incorporated to keep the cutting tools and workpiece at appropriate temperatures, prolonging tool life and improving machining accuracy.

- Guideways and Linear Motion Systems:

- These systems enable smooth and precise movement of the machine components, ensuring accurate machining.

- Safety Features:

- Used MAKINO Machining Center s are equipped with safety features like emergency stop buttons, interlocks, and safety guards to ensure operator safety during machine operation.

Used MAKINO Machining Center s are widely used in various industries, including automotive, aerospace, medical, and manufacturing, due to their ability to produce complex and high-precision parts efficiently. CNC programming allows for a high level of automation, accuracy, and repeatability in manufacturing processes.

Why Choose VIGERT?

VIGERT is a professional used metalworking machine dealer in China for many years, our productions have been sold to over 100 countries in the world!

Reviews

There are no reviews yet.