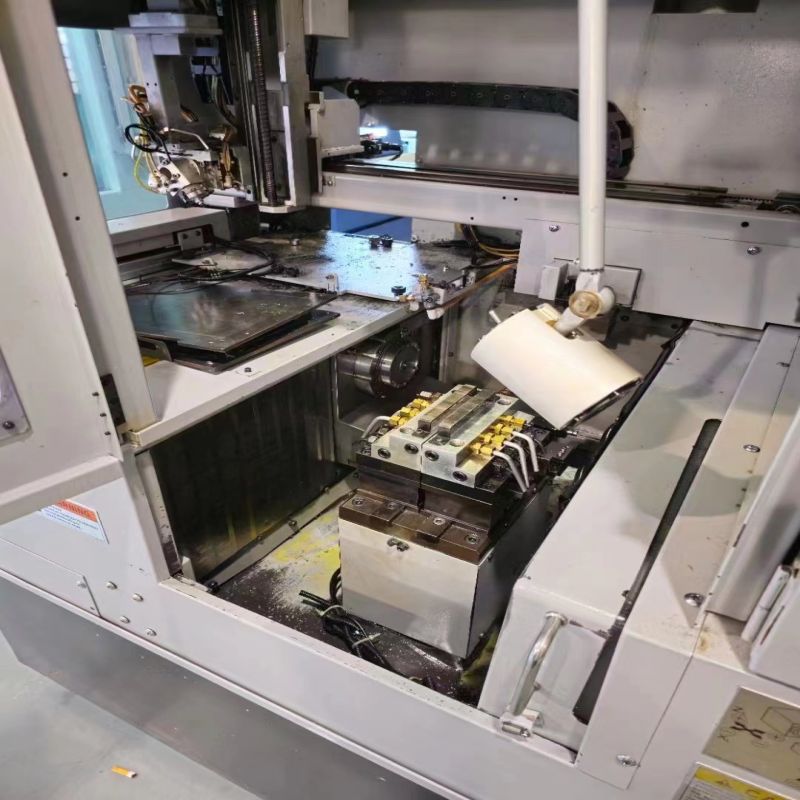

Used TSUGAMI C180 High Precision Double Spindle Lathe For Sale

| Weight | 400000 kg |

|---|---|

| Condition |

90% New |

| MFG Year |

2010 |

| Origin |

China |

| Payment Method |

LC ,T/T |

| Price Term |

EXW |

| Brand |

TSUGAMI |

| Warranty |

One Year |

| Model |

High |

| Function |

Milling |

18

People watching this product now!

Description

High Precision Double Spindle Lathe, his design allows for simultaneous machining of a workpiece from both ends, improving efficiency and reducing cycle times. Here’s a detailed breakdown of its key components and functionalities:

- Spindles: High Precision Double Spindle Lathe. A double spindle lathe has two spindles, typically located on opposite ends of the lathe bed. Each spindle is independently motorized and equipped with its own chuck to hold the workpiece securely during machining.

- Tooling: High Precision Double Spindle Lathe. Each spindle is equipped with a set of cutting tools for various turning operations such as facing, turning, drilling, and threading. The tooling setup allows for complex and precise machining operations.

- Bed and Guideways: High Precision Double Spindle Lathe. The lathe bed provides the foundation and rigidity for the machine. It supports the spindles and other critical components. Precision guideways ensure smooth and accurate movement of the cutting tools and workpieces.

- Workholding: Workholding devices like chucks, collets, and fixtures are used to securely hold the workpiece in place during machining. These are attached to the spindles and provide stability and precision during turning operations.

- Control System (CNC): The lathe is typically controlled by a computer numerical control (CNC) system. This allows for precise control over tool movements, spindle speeds, feed rates, and other machining parameters. CNC programming enables automation and repeatability.

- Tool Turrets: Double spindle lathes often have multiple tool turrets associated with each spindle. Tool turrets can hold a variety of cutting tools and quickly change tools during the machining process, allowing for efficient and versatile operations.

- Coolant and Chip Management: A coolant system is used to keep the cutting tools and workpieces cool during machining, improving tool life and surface finish. Chip management systems help remove chips and swarf from the machining area for efficient operation.

Reviews (0)

Be the first to review “Used TSUGAMI C180 High Precision Double Spindle Lathe For Sale” Cancel reply

About VIGERT

Why Choose VIGERT?

VIGERT is a professional used metalworking machine dealer in China for many years, our productions have been sold to over 100 countries in the world!

Reviews

There are no reviews yet.